Cutter handle heater and operation method thereof

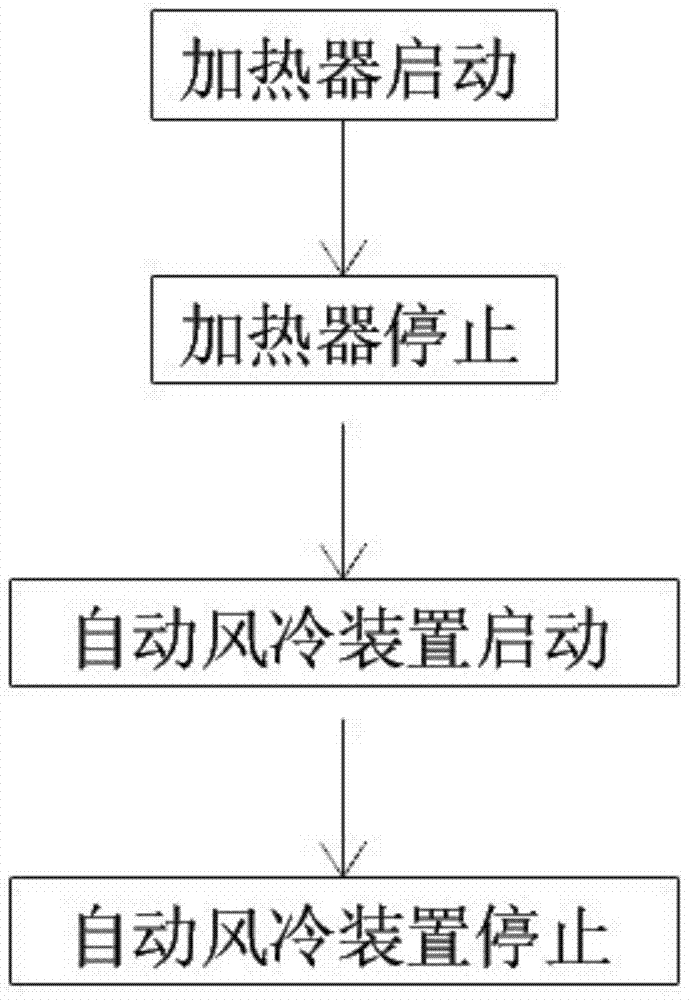

A heater and tool handle technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to set the precise time and temperature of the tool handle heating, poor heating effect, damage to the tool, etc., to achieve structural Simple, good heating effect, accurate heating control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

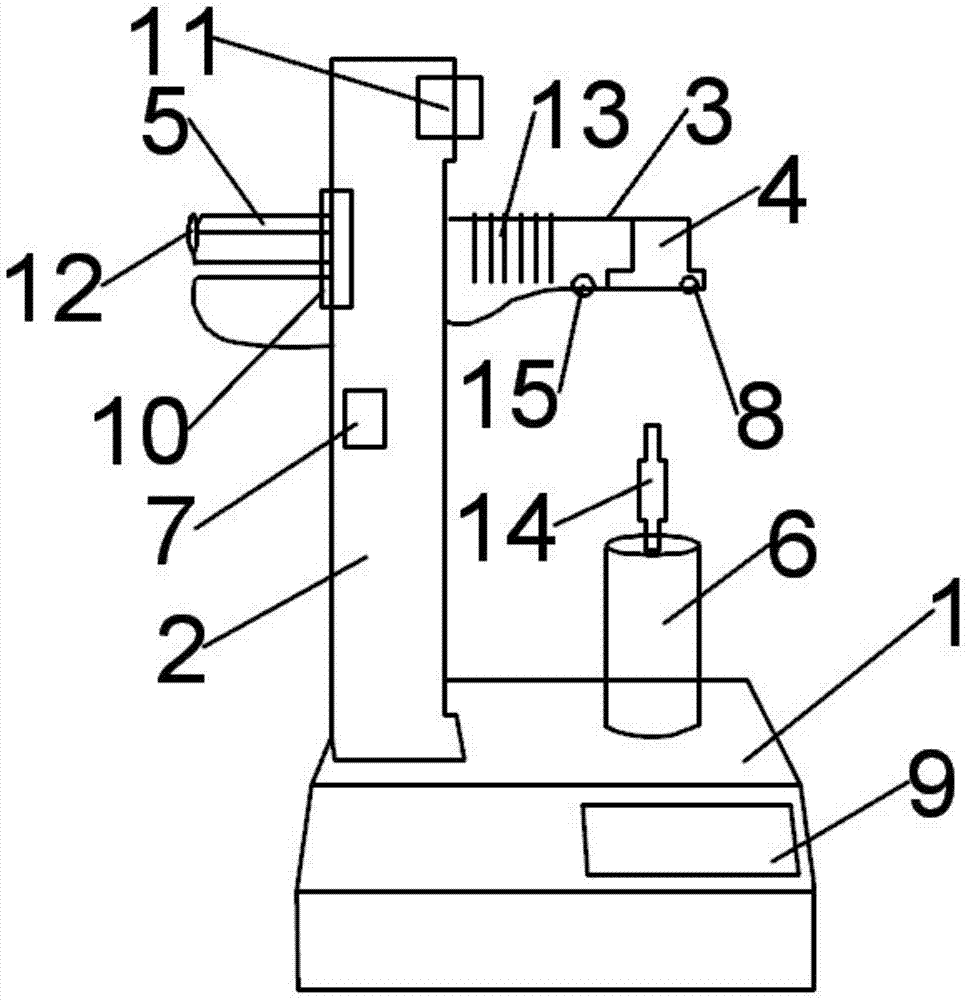

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings. Only the main parts related to the present invention are marked in the figure, and this figure is only a model, without any size or proportion limitation.

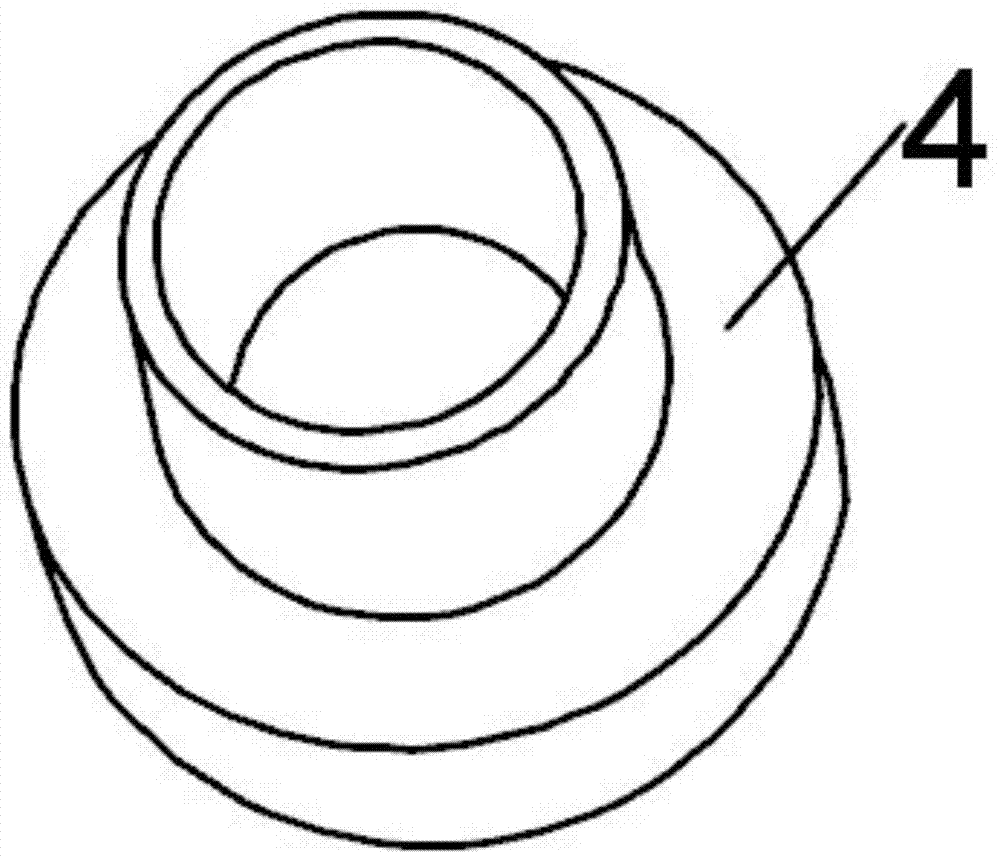

[0026] Such as figure 1 As shown, the present invention provides a kind of handle heater, and described handle heater comprises working platform 1, and one side of described working platform 1 is provided with lifting support 2, and lifting support 2 is provided with can lift support 2 The heating device 3 that rises and falls, the heating device 3 includes a heat gun 4 and a heat gun body 5 and is respectively arranged on the inner and outer sides of the lifting bracket 2, and a working platform 1 directly below the heat gun 4 is provided with a For the base 6 of the fixed cutter 14, the base 6 is optional, and different types of handles have corresponding bases 6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com