Preparation method of rare earth doped LiNi0.5 Mn1.5O4 as anode material for super capacitor

A technology for supercapacitors and cathode materials, which is applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problems of low specific capacity and high cost, and achieve the effects of good crystalline performance, improved conductivity and high purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

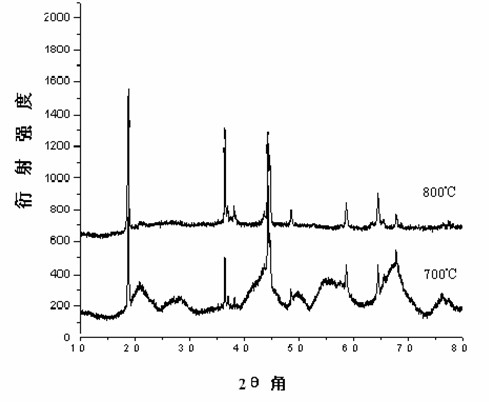

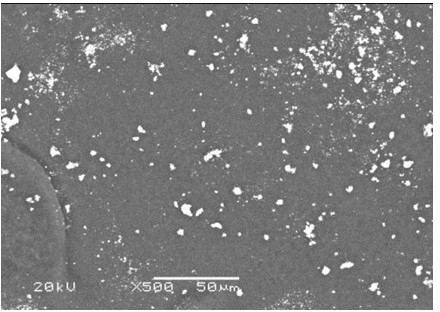

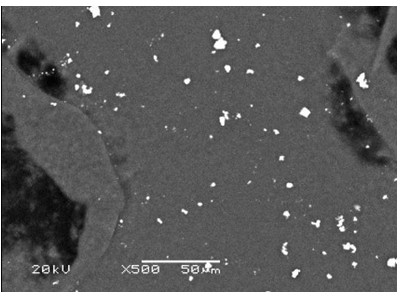

Image

Examples

Embodiment 1

[0032]A supercapacitor cathode material rare earth doped LiNi 0.5 mn 1.5 o 4 The preparation method comprises the following steps:

[0033] (1) 18650 grams of nickel acetate Ni(CH 3 COO) 2 4H 2 O, 55150 grams of manganese acetate Mn (CH 3 COO) 2 4H 2 O, 6720 g lithium hydroxide LiOH·H 2 O is added in the reaction tank; Add 270Kg of pure water, stir and make it dissolve, obtain solution A;

[0034] (2) Measure 5400 grams of citric acid and 81Kg of purified water respectively, add citric acid into purified water, stir well to obtain an aqueous solution of citric acid; then add 258 grams of cerium oxide and 150 grams of sodium tripolyphosphate and stir well to obtain citric acid , Mixture B of cerium oxide;

[0035] (3) Slowly add solution B to solution A while stirring, and continue stirring for about 20 minutes to obtain solution C;

[0036] (4) Add ammonia water dropwise to solution C, adjust its pH to 5-7, and then stir for 20-40 minutes;

[0037] (5) Put the pH-a...

Embodiment 2

[0041] A supercapacitor cathode material rare earth doped LiNi 0.5 mn 1.5 o 4 The preparation method comprises the following steps:

[0042] (1) 21811 grams of nickel nitrate Ni(NO 3 ) 2 ·6H 2 O, 55150 grams of manganese acetate Mn (CH 3 COO) 2 4H 2 O, 6090 grams of lithium carbonate (Li 2 CO 3 ) into the reaction tank; add 405Kg of pure water, stir to dissolve it, and obtain solution A;

[0043] (2) Measure 5400 grams of citric acid and 135Kg of purified water respectively, add citric acid into purified water, stir well to obtain an aqueous solution of citric acid; then add 245 grams of lanthanum oxide La 2 o 3 , 60 gram sodium hexametaphosphate, fully stir, obtain the mixed solution B of citric acid, lanthanum oxide;

[0044] (3) Slowly add solution B to solution A under stirring, and continue stirring for about 20 minutes to obtain solution C;

[0045] (4) Add ammonia water dropwise to solution C, adjust its pH to 5-7, and then stir for 20-40 minutes;

[0046]...

Embodiment 3

[0050] A supercapacitor cathode material rare earth doped LiNi 0.5 mn 1.5 o 4 The preparation method comprises the following steps:

[0051] (1) 18650 grams of nickel acetate Ni(CH 3 COO) 2 4H 2 O, 55150 grams of manganese acetate Mn (CH 3 COO) 2 4H 2 O, 6200 grams of lithium carbonate (Li 2 CO 3 ) into the reaction tank; add 300Kg of pure water, stir to dissolve it, and obtain solution A;

[0052] (2) Measure 5400 grams of citric acid and 135 Kg of purified water respectively, add citric acid to purified water, and stir evenly to obtain an aqueous solution of citric acid; then add 130.5 grams of dipraseodymium trioxide and 40 grams of sodium pyrophosphate to fully stir to obtain lemon Mixture B of acid and praseodymium trioxide;

[0053] (3) Slowly add solution B to solution A under stirring, and continue stirring for about 20 minutes to obtain solution C;

[0054] (4) Add ammonia water dropwise to solution C, adjust its pH to 5-7, and then stir for 20-40 minutes;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com