Method for preparing spinel lithium titanate of cathode material of lithium ion battery

A lithium-ion battery and negative electrode material technology, applied in the direction of electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of poor conductivity, high cost, low specific capacity of titanium oxide compounds, etc., achieve good crystallization performance, improve conductivity, The effect of shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

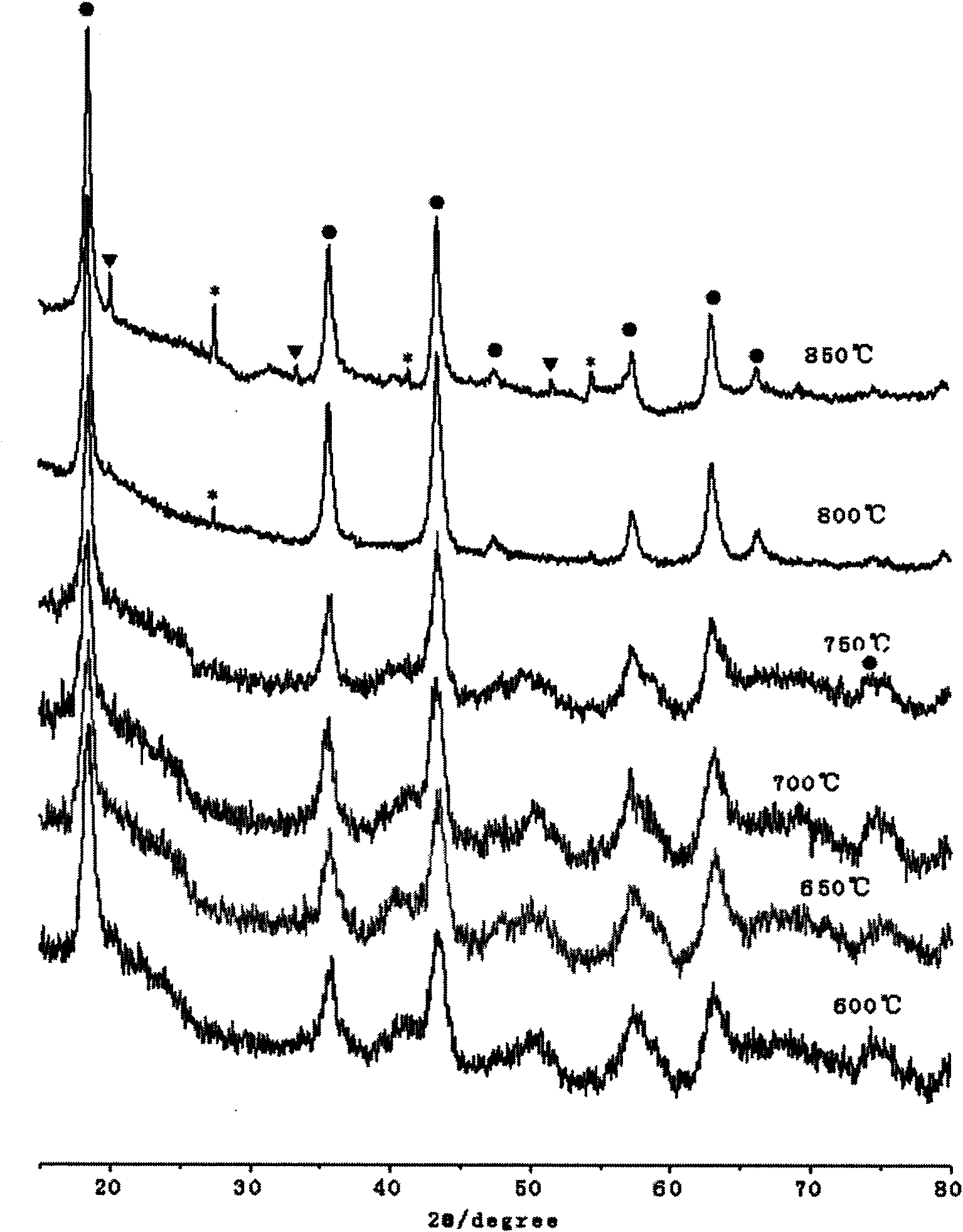

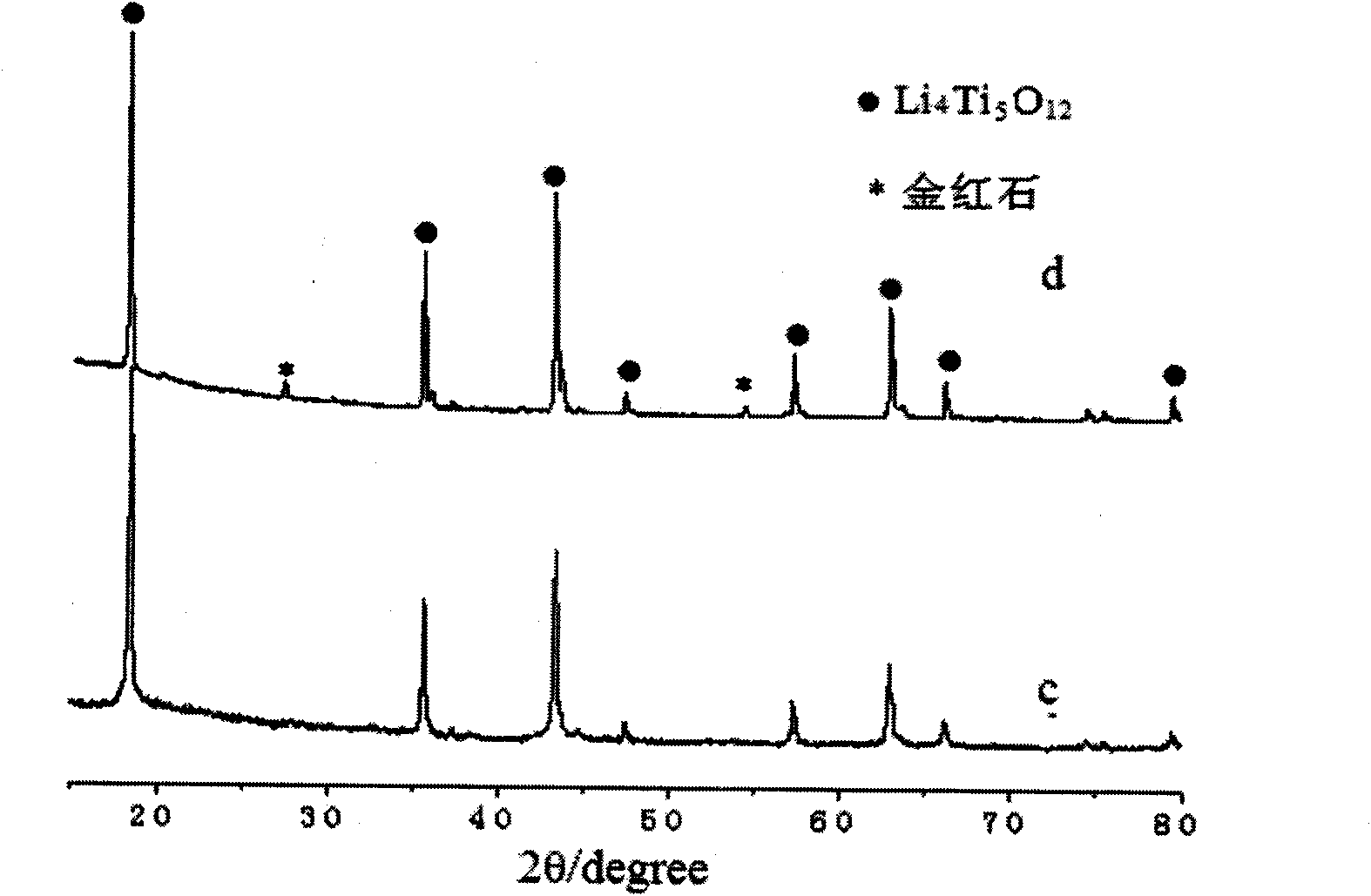

[0050] Embodiment one: a kind of lithium-ion battery negative electrode material Li 4 Ti 5 o 12 The preparation method comprises the following steps:

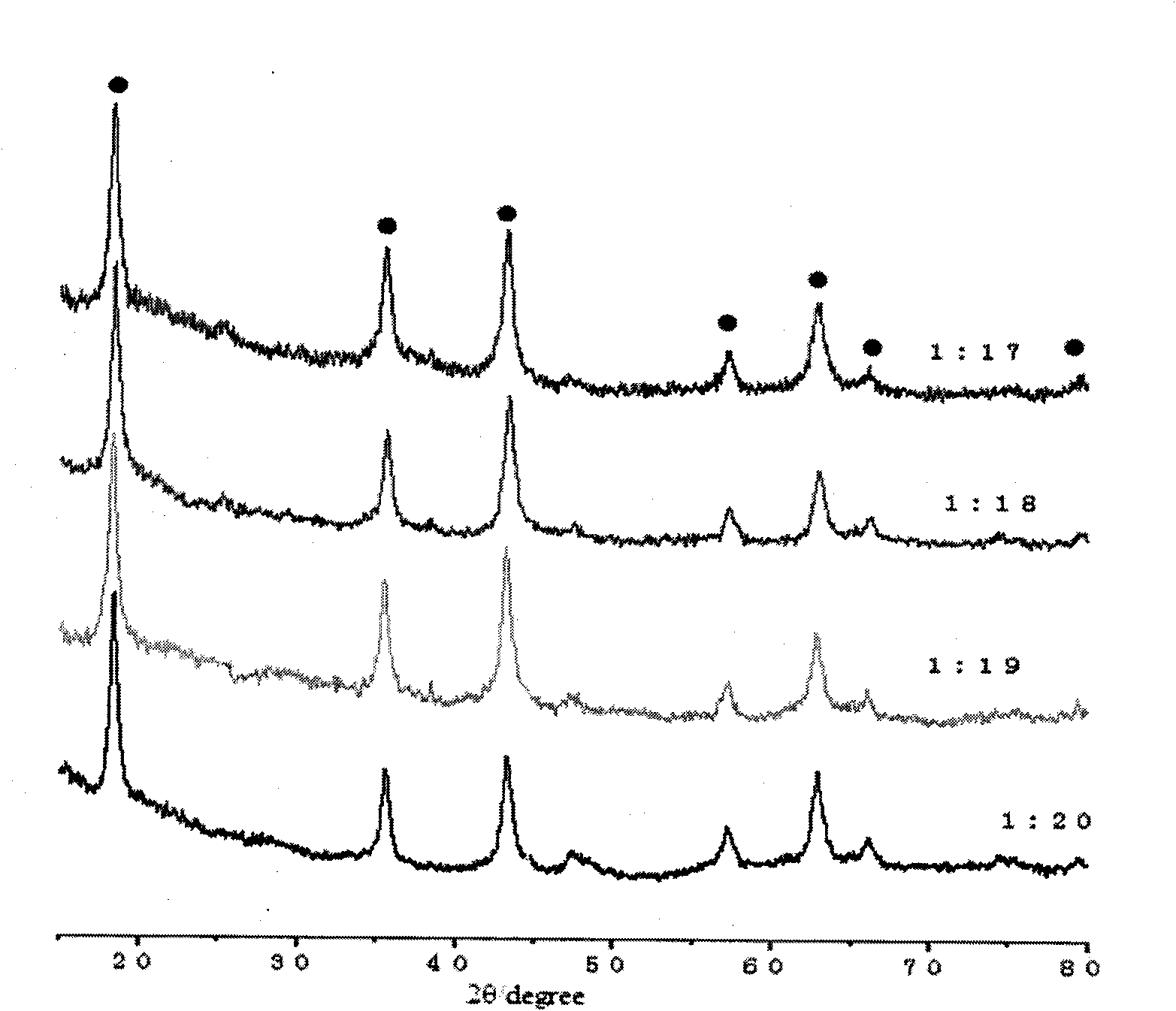

[0051] (1) Weigh butyl titanate, absolute ethanol, and acetylacetone at a molar ratio of 5:9:3; after mixing the absolute ethanol and acetylacetone evenly, add butyl titanate while stirring to prepare A mixed solution of butyl titanate and ethanol; acetylacetone is used as a solvent in this reaction.

[0052] (2) According to the molar ratio of lithium hydroxide, citric acid, deionized water, absolute ethanol and butyl titanate as 3.8:2.5:5.5:5.4:5, weigh lithium hydroxide, citric acid, deionized water, and Ionized water and absolute ethanol, after mixing citric acid and absolute ethanol evenly, add lithium hydroxide to dissolve it, then add deionized water, and mix evenly; the lithium hydroxide in it is LiOH or LiOH·H 2 O can be.

[0053] (3) Slowly add the mixed solution of butyl titanate and ethanol prepared in step (1)...

Embodiment 2

[0057] Embodiment two: a kind of lithium ion battery anode material Li 4 Ti 5 C 12 The preparation method comprises the following steps:

[0058] (1) Weigh butyl titanate, absolute ethanol, and acetylacetone at a molar ratio of 5:9.5:3.8; after mixing the absolute ethanol and acetylacetone evenly, add butyl titanate while stirring to prepare Butyl titanate, ethanol mixed solution;

[0059] (2) Weigh lithium hydroxide, citric acid, deionized water, and Ionized water and absolute ethanol, after mixing citric acid and absolute ethanol evenly, add lithium hydroxide to dissolve in it, then add deionized water, and mix evenly;

[0060] (3) slowly adding the mixed solution prepared in step (1) into the solution obtained in step (2) under vigorous stirring to obtain a uniform and transparent sol precursor;

[0061] (4) Continue to stir for 40 minutes, and age for 5 hours until the sol turns into a gel;

[0062] (5) Drying by microwave at a drying temperature of 90°C and a drying...

Embodiment 3

[0064] Embodiment three: a kind of lithium-ion battery negative electrode material Li 4 Ti5 o 12 The preparation method comprises the following steps:

[0065] (1) Weigh butyl titanate, absolute ethanol, and acetylacetone at a molar ratio of 5:9.3:3.5; after mixing the absolute ethanol and acetylacetone evenly, add butyl titanate while stirring to prepare Butyl titanate and ethanol mixed solution;

[0066] (2) Weigh lithium hydroxide, citric acid, deionized water, and Ionized water and absolute ethanol, mix citric acid and absolute ethanol evenly, add lithium hydroxide to dissolve in it, and then add deionized water;

[0067] (3) slowly adding the mixed solution prepared in step (1) into the solution obtained in step (2) under vigorous stirring to obtain a uniform and transparent sol precursor;

[0068] (4) Continue to stir for 25 minutes, and age for 3 hours until the sol turns into a gel;

[0069] (5) Drying by microwave, the drying temperature is 75°C, and the drying t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com