High-precision temperature-controlled crystal oscillator

A crystal oscillator, high-precision technology, applied in power oscillators, instruments, temperature control and other directions, can solve the problems of increased material costs, large temperature fluctuations of the thermostatic bath body, and imprecise temperature control, so as to reduce production costs. , Competitive and finely controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

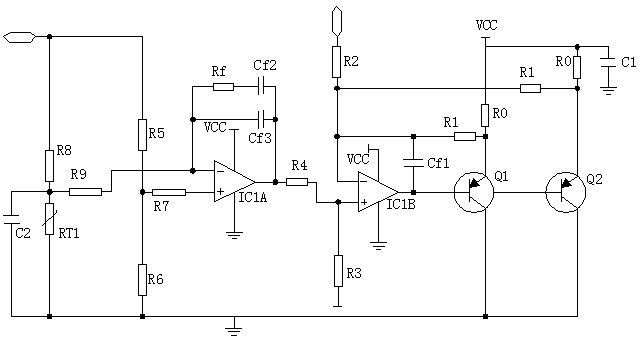

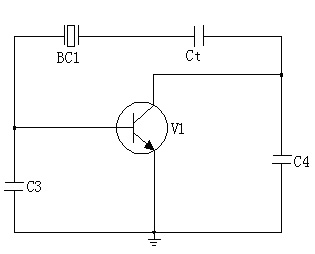

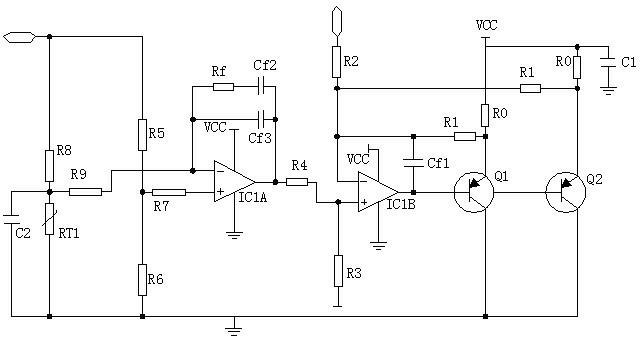

[0016] In this example, refer to figure 1 with figure 2 , the high-precision temperature-controlled crystal oscillator, the circuit of the oscillator includes a temperature-control circuit and a circuit of the main vibration part, the circuit of the temperature-control circuit includes a thermistor RT1 with a negative temperature coefficient, two operational amplifiers IC1A, IC1B , two PNP transistors Q1 and Q2; one end of the thermistor RT1 is grounded, the other end is connected to the temperature control point adjustment resistor R8, the other end of the resistor R8 is connected to the resistor R5, the resistor R5 is connected to the resistor R6, and the other end of the resistor R6 is grounded; the resistor R8 is connected to the thermal A connection resistor R9 is connected between the sensitive resistors RT1, the resistor R9 is connected to the inverting terminal of the operational amplifier IC1A, the same phase terminal of the operational amplifier IC1A is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com