Rapid cooling device and temperature control method thereof

A fast heating and cooling technology, applied in the direction of temperature control, non-electric variable control, control/regulation system, etc., can solve the problem of SCR's large size, increased use of influence, AC and DC control signals and output power circuit noise interference, etc. problems, to achieve the effect of reducing volume, reducing noise and interference, and precise control of cavity heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The implementation of the present invention will be described in more detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it after studying this specification.

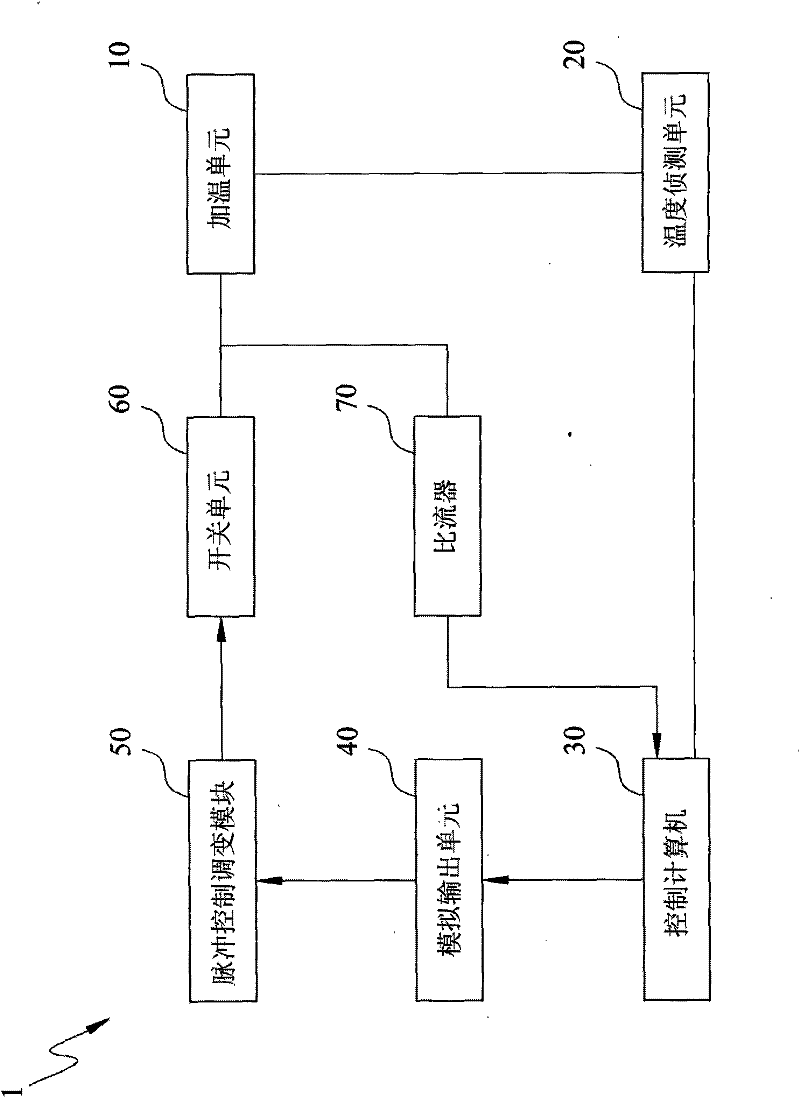

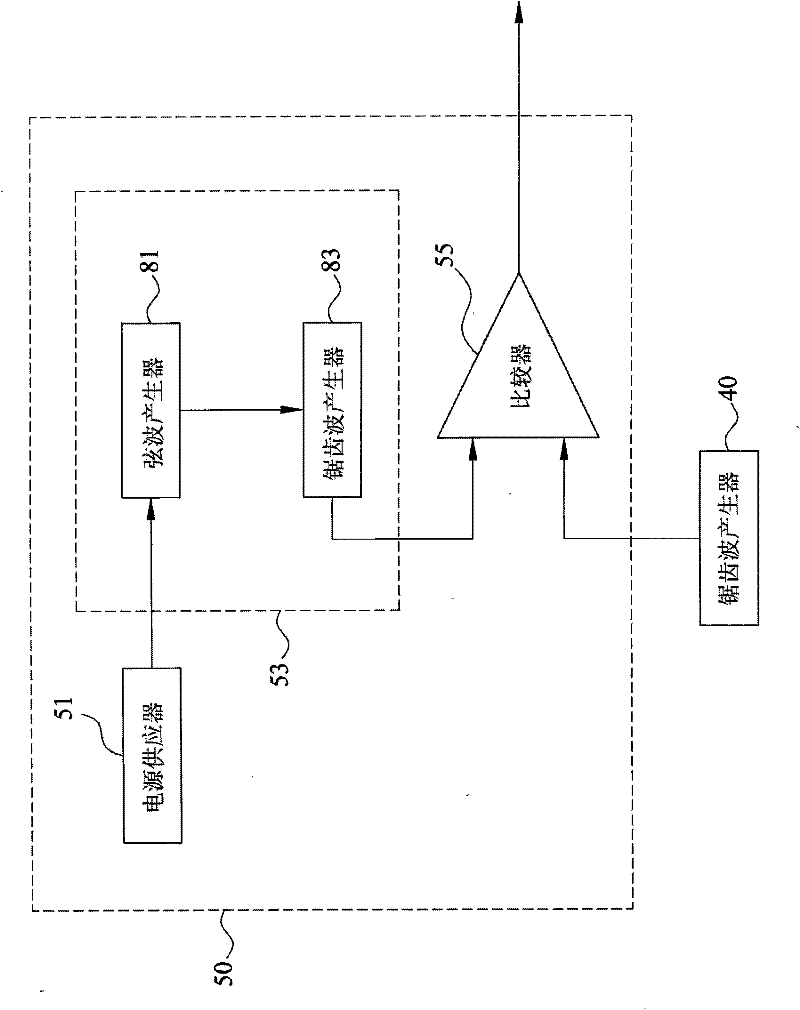

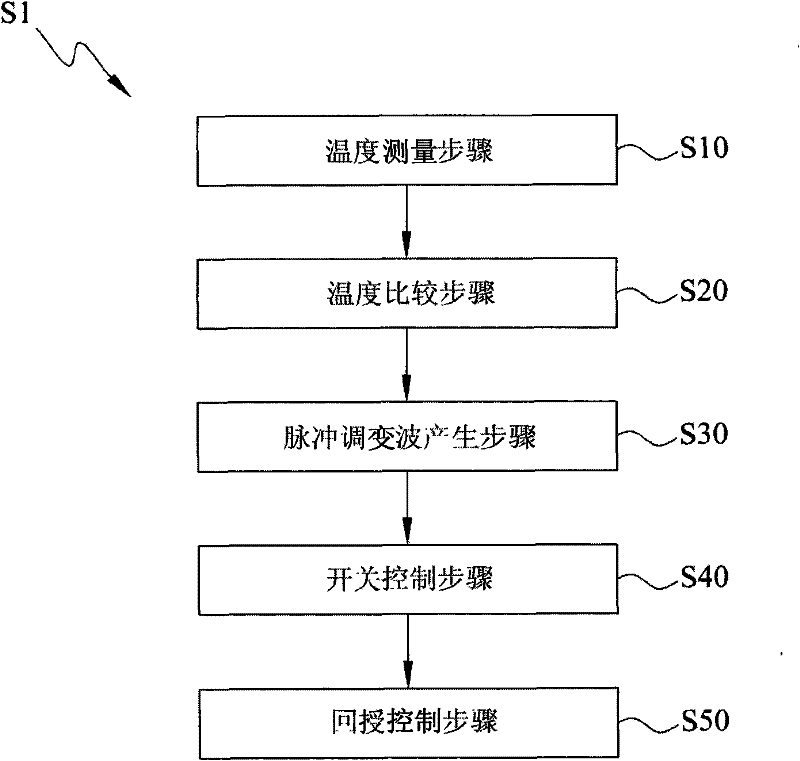

[0014] refer to figure 1 , is a schematic block diagram of the rapid heating and cooling device of the present invention. Such as figure 1 As shown, the rapid heating and cooling device 1 of the present invention includes a heating unit 10, a temperature detection unit 20, a control computer 30, an analog output unit 40, a pulse control modulation module 50, and a switch unit 60. The heating unit 10 includes a A cavity (not shown) containing an object to be heated and a plurality of heater arrays (not shown), the temperature detection unit 20 is connected to the heating unit 10 for measuring the temperature of the cavity in the heating unit 10 temperature, the control computer 30 is connected to the temperature detection unit 20, includes a temperature co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com