Device and method for removing methanol from methyl tert-butyl ether cracking product

A technology of methyl tert-butyl ether and pyrolysis products, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc. It can solve problems such as insufficient gas-liquid contact, unsatisfactory mass transfer effect, and short contact time. Achieve full absorption effect, reduce the circulation of absorption liquid, and increase the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

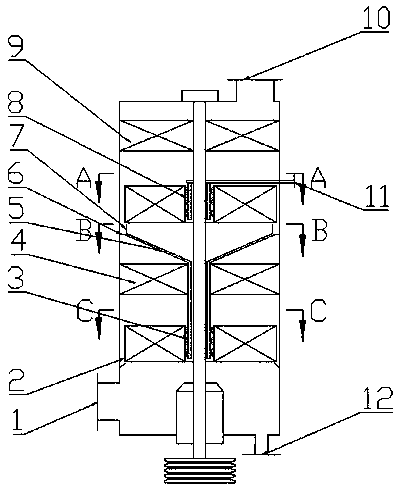

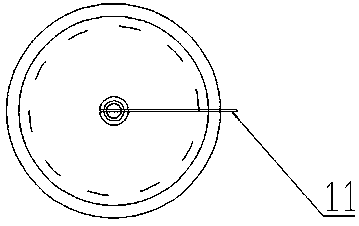

[0048] like Figure 1~5 Shown, a kind of device that removes methanol from the cracking product of methyl tert-butyl ether comprises multistage gas flow shearing cross-flow bed 16, and the bottom of multistage gas flow shearing cross flow bed 16 sides is provided with gas inlet 1, through Into the cracked gas, the top of the multi-stage air flow shearing cross-flow bed 16 is provided with a gas outlet 10, which is connected with the purification gas section, and the top of the side of the multi-stage air flow shearing cross-flow bed is provided with a liquid inlet 11, which is used to feed the absorption liquid. The bottom of the multi-stage air shearing cross-flow bed 16 is provided with a liquid outlet 12 for discharging the absorption liquid, the liquid inlet is connected to the pump, and the liquid outlet 11 of the multi-stage air shearing cross-flow bed is connected to the methanol rich liquid tank 18;

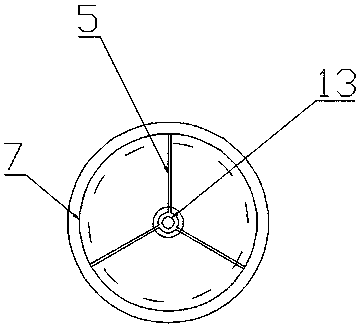

[0049] The multi-stage air shear cross-flow bed 16 includes a liquid...

Embodiment 1

[0060] MTBE pyrolysis product composition (mass fraction): isobutene: 97.4%; methanol: 1.44%; dimethyl ether: 1.13%; the rest is a trace of MTBE and tertiary alcohol.

[0061] Turn on the motor, adjust the rotor of the multi-stage air-shear cross-flow bed to 1800r / min, turn on the lean liquid pump, adjust the liquid flow meter to control the flow rate of water solvent to 30L / h, and the methanol aqueous solution enters the multi-stage air-shear cross-flow bed from the liquid inlet , the MTBE cracking product containing 1.44% methanol is passed through the gas inlet into the multi-stage gas flow shearing cross-flow bed, and the gas volume is adjusted to 3m 3 / h, the liquid is evenly distributed and sprayed into the upper and lower layers of packing through the upper and lower liquid distributors, and moves outward along the inner layer of the packing under the action of huge centrifugal force. , to remove methanol gas, the purified gas from the gas outlet is passed into the purif...

Embodiment 2

[0063] The technological process is the same as that of Example 1, and the factors investigated in Example 2 are different gas flow rates, liquid flow rates, and rotor speeds, and the content (mass fraction) of methanol at the gas outlet of the multistage gas flow sheared cross-flow bed is analyzed. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com