Ammonia-acid method SO2 tail gas adsorption process using dynamic wave washer

A dynamic wave washing, SO2 technology, applied in chemical instruments and methods, separation methods, dispersed particle separation and other directions, can solve the problems of complex equipment structure, crystal blockage of tray sieve holes, large investment, etc., to achieve low investment and simple operation. , Guarantee the effect of up-to-standard emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

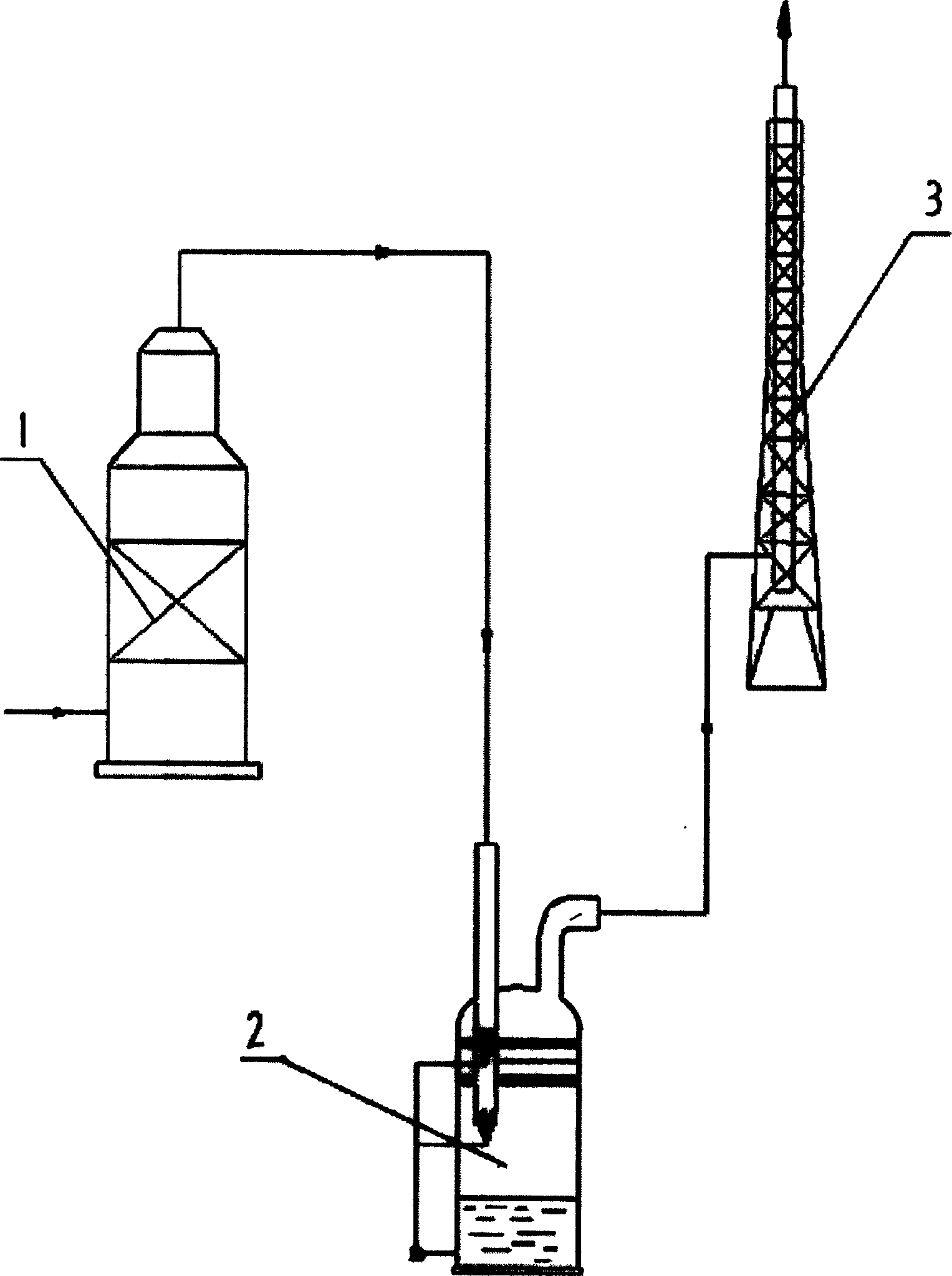

[0021] Such as figure 1 : For sulfuric acid tail gas SO 2 For unqualified acid production systems, the last SO in the sulfuric acid process 3 SO contained in the absorption tower 1 2 The tail gas is connected to the reverse nozzle 3 of the dynamic wave scrubber 2 . The flue gas flows from top to bottom and absorbs SO through the mother liquor 2 Finally, it is discharged by the outlet pipe of the dynamic wave scrubber, and is discharged into the atmosphere through the exhaust gas chimney 3.

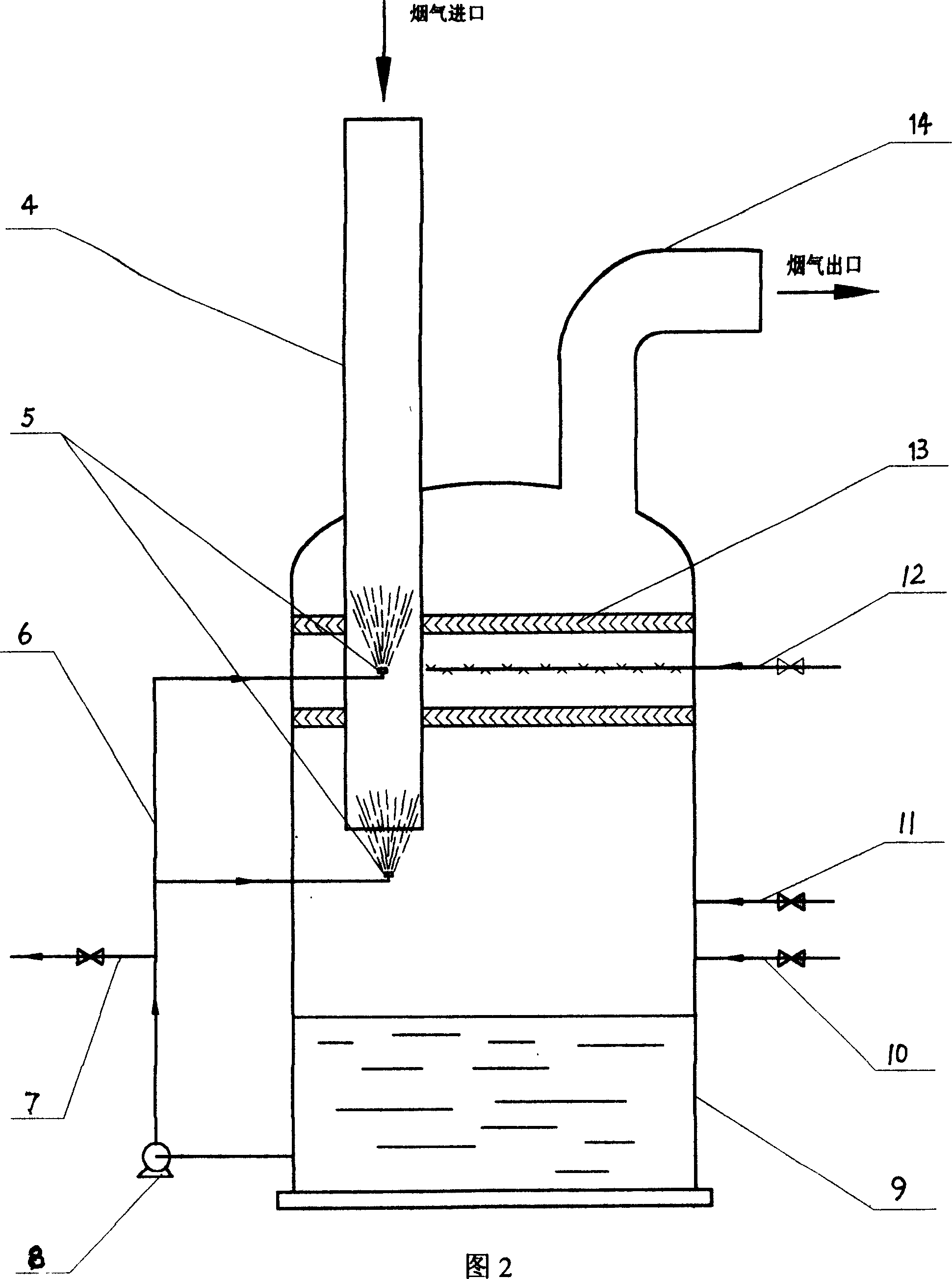

[0022] The working process of the dynamic wave scrubber is illustrated by Figure 2: 2 The flue gas enters the reverse nozzle pipe 4 of the power wave scrubber from top to bottom through the inlet of the power wave scrubber, and the circulating liquid is sent into the reverse nozzle pipe by the mother liquor circulation pump 8 through the upper liquid pipe 6, and is reversed from the nozzle 5 to the direction of the airflow from bottom to top The gas-liquid reversely collides to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com