A rotary bed and a recovery method of hydrocarbon-containing exhaust gas

A technology of rotating bed and rotating shaft, applied in the direction of liquid hydrocarbon mixture recovery, separation method, chemical instrument and method, etc., can solve the problems of long process flow, undisclosed prior art, economic impact, etc., and achieve simple device structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A certain gasoline oxidative sweetening tail gas and liquid hydrocarbon oxidative sweetening tail gas, the temperature is about 40°C, and the total hydrocarbon concentration is 30×10 4 ~80×10 4 mg / m 3 . The absorbent is crude kerosene from the fractionation tower of the refinery at a temperature of 60°C.

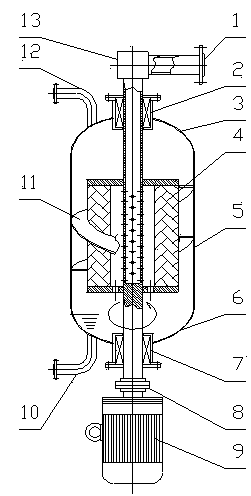

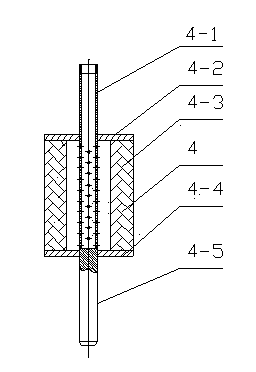

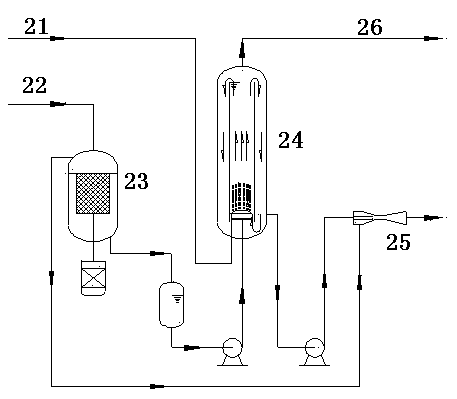

[0035] Gas oil enters as figure 1 For the rotary bed shown in the structure, the bed rotation speed is 600 rpm. The liquid phase discharged from the rotating bed is cooled to 20°C and enters the bubbling bed with waste gas for hydrocarbon absorption. The gas space velocity in the bubbling bed is 60h -1 , the volume ratio of the absorbent at the inlet of the bubbling bed to the exhaust gas is 0.1, and the rich absorbent discharged from the bubbling bed and the gas phase discharged from the rotating bed are reabsorbed and mixed by an ejector, and then used as feed to the kerosene hydrotreating unit, and the tail gas is discharged The hydrogen sulfide content in th...

Embodiment 2

[0041] Exhaust gas is discharged from an oil storage tank area, the temperature is about 40°C, and the total hydrocarbon concentration is 10×10 4 ~50×10 4 mg / m 3 . The absorbent is the gas oil from the fractionation tower of the catalytic cracking unit of the refinery, and the temperature is 60°C.

[0042] Gas oil enters as figure 1 For the rotary bed shown in the structure, the bed rotation speed is 1000 rpm. The liquid phase discharged from the rotating bed is cooled to 25°C and enters the bubbling bed with waste gas for hydrocarbon absorption. The gas space velocity in the bubbling bed is 150h -1 , the volume ratio of the absorbent at the inlet of the bubbling bed to the exhaust gas is 0.2, and the rich absorbent discharged from the bubbling bed and the gas phase discharged from the rotating bed are reabsorbed and mixed by an injector, and then used as feedstock for a diesel hydrotreating unit, and the tail gas is discharged The hydrogen sulfide content in the medium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com