Low-carbon source high-ammonia nitrogen high-organic phosphor waste water combined type biological bed treatment technology

A treatment process, high ammonia nitrogen technology, applied in the direction of biological water/sewage treatment, water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problem that the treatment method is difficult to fully adapt, cannot meet the discharge standard, and the removal efficiency of ammonia nitrogen is low, etc. problems, achieve the effects of reducing operating costs and operating workload, improving biochemical treatment efficiency, and improving the Fenton effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

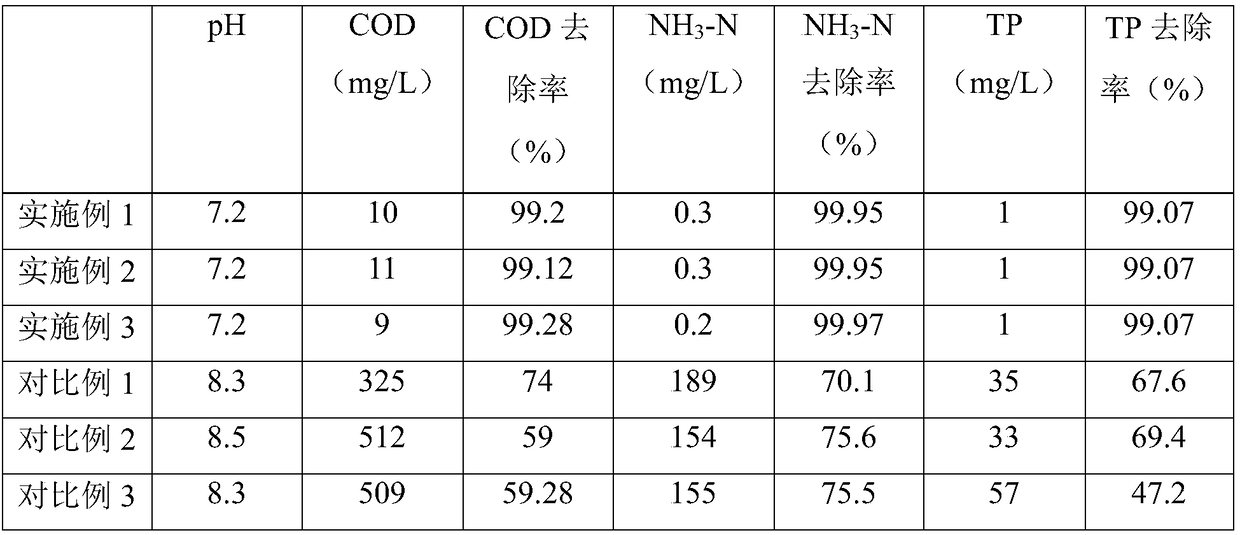

Embodiment 1

[0045] The combined biological bed treatment process of low-carbon source, high ammonia nitrogen and high organic phosphorus wastewater includes five steps: raw water adjustment, iron carbon-Nefton treatment, struvite treatment, A2O treatment, and Fenton advanced treatment, as follows:

[0046] S1. Raw water adjustment

[0047] Raise the waste water to the adjustment tank and adjust the pH=5.

[0048] S2. Iron carbon-Nefton treatment

[0049] (1) utilize the sulfuric acid solution of mass concentration 10% to adjust pH=3, add the hydrogen peroxide aqueous solution of mass concentration 30% simultaneously, by volume, the hydrogen peroxide aqueous solution add-on is 3‰ of total water;

[0050] (2) adding iron-carbon filler, the filling ratio is 40% (weight), the aeration rate is 60L / min, and the reaction time is 5 hours;

[0051] (3) Use 20% sodium hydroxide solution to adjust the pH to 7.5, add the first flocculant, and settle in the sedimentation tank for 2 hours; add 1 g of...

Embodiment 2

[0067] The combined biological bed treatment process of low-carbon source, high ammonia nitrogen and high organic phosphorus wastewater includes five steps: raw water adjustment, iron carbon-Nefton treatment, struvite treatment, A2O treatment, and Fenton advanced treatment, as follows:

[0068] S1. Raw water adjustment

[0069] Raise the waste water to the adjustment tank, and adjust the pH=6.

[0070] S2. Iron carbon-Nefton treatment

[0071] (1) utilize the sulfuric acid solution of mass concentration 25% to adjust pH=4, add the hydrogen peroxide aqueous solution of mass concentration 30% simultaneously, by volume, the hydrogen peroxide aqueous solution add-on is 3‰ of total water yield;

[0072] (2) adding iron-carbon filler, the filling ratio is 40% (weight), the aeration rate is 60L / min, and the reaction time is 5 hours;

[0073] (3) Adjust the pH to 8 with a sodium hydroxide solution with a mass concentration of 30%, add the first flocculant, and settle in the sediment...

Embodiment 3

[0089] The combined biological bed treatment process of low-carbon source, high ammonia nitrogen and high organic phosphorus wastewater includes five steps: raw water adjustment, iron carbon-Nefton treatment, struvite treatment, A2O treatment, and Fenton advanced treatment, as follows:

[0090] S1. Raw water adjustment

[0091] Raise the waste water to the adjustment tank and adjust the pH=5.

[0092] S2. Iron carbon-Nefton treatment

[0093] (1) utilize the sulfuric acid solution of mass concentration 20% to adjust pH=3, add the hydrogen peroxide aqueous solution of mass concentration 30% simultaneously, by volume, the hydrogen peroxide aqueous solution add-on is 3‰ of total water;

[0094] (2) adding iron-carbon filler, the filling ratio is 40% (weight), the aeration rate is 60L / min, and the reaction time is 5 hours;

[0095] (3) Adjust the pH to 8 with a sodium hydroxide solution with a mass concentration of 25%, add the first flocculant, and settle in the sedimentation t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com