Multi-stage composite processing technology of high-concentration organic sewage

A technology of organic wastewater and treatment process, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Incomplete adaptation and other problems, to achieve good social and economic benefits, improve the efficiency of biochemical treatment, and improve the effect of biochemical treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

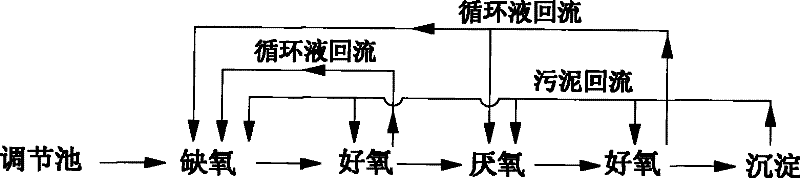

[0034] Such as figure 1 , Figure 1A As shown, the present embodiment provides a method for treating high-concentration chemical organic wastewater by a multi-stage combined process, which mainly includes pretreatment biochemical treatment, and the process includes the following treatment steps:

[0035] 1) Firstly, introduce high-concentration wastewater into the regulating tank 1, which can be equipped with a liquid level controller and a time controller to control the opening of the lifting pump, which can adjust the water quality and volume of the wastewater, and lift the wastewater into the subsequent process deal with;

[0036] 2) The wastewater enters the anoxic pool through the regulating pool 1. Under the anoxic condition, the anoxic denitrifying bacteria use the organic matter as the electron donor, the combined oxygen respiration in the nitrate nitrogen, and the nitrate or nitrite as the electron acceptor To carry out metabolic activities, oxidize and decompose or...

Embodiment 2

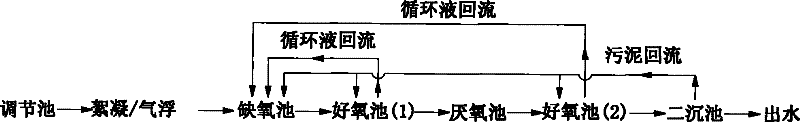

[0055] Such as figure 2 As shown, the utility model can also be provided with a pretreatment step before the biochemical treatment, and can perform preliminary treatment on wastewater with more impurities and suspended matter content, and the pretreatment step includes catalytic oxidation, flocculation / precipitation, Flocculation / air flotation, anaerobic / sedimentation, stripping treatment single, partial or all process combination. Such as Figure 2A As shown, this embodiment specifically introduces high-concentration wastewater into the regulating tank 1, and then sets the flocculation tank 2 and the air flotation tank 3. Dissolved air is blown into the water outlet. Pretreatment can remove suspended solids in raw water and partially remove dissolved organic pollutants, so as to reduce the pollutant treatment load of the main biochemical process.

[0056] When the removal rate of pretreatment pollutants is less than 50%, the pH value should be adjusted, and appropriate fl...

Embodiment 3

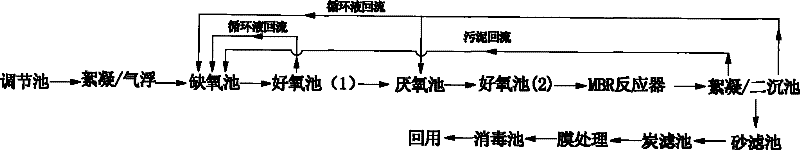

[0065] Such as image 3 As shown, in this embodiment, treatment steps are provided before and after the biochemical treatment of the organic wastewater, so that the water quality can reach the reuse water standard. Wherein the pretreatment step can be treated according to the second embodiment, and the posttreatment step includes at least one membrane bioreaction, or simultaneous catalytic oxidation, flocculation / sedimentation, sand filtration, carbon filtration, ultrafiltration, reverse osmosis, and disinfection In the above-mentioned catalytic oxidation, flocculation / sedimentation, sand filtration, carbon filtration, ultrafiltration, reverse osmosis, and disinfection treatment steps, any one of the treatment steps can be selected to be carried out alone with the membrane biological reaction, and it can also be considered according to the biochemical physiology of high-concentration organic wastewater. effluent COD Cr 、BOD 5 The predicted data and their ratios of the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com