Horizontal suspension sludge air-lift backflow method

A technique of suspended sludge and airlift reflux, applied in water/sludge/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc. The method cannot efficiently complete the reflow task, the area is large, etc., to achieve the effect of long reflow route, ensuring consistency, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

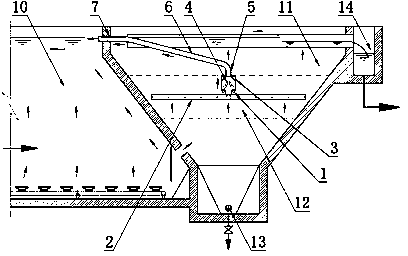

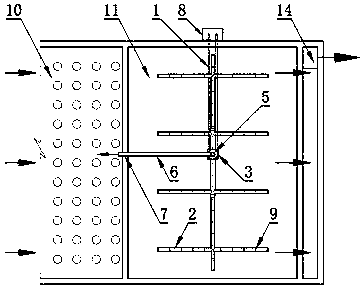

[0026] In the following, the present invention will be further described by referring to the accompanying drawings and using the horizontal suspended sludge airlift and reflux method of the present invention as an example in conjunction with an activated sludge process sewage treatment tank.

[0027] From figure 1 and figure 2 It can be seen from the figure that this reflux method adopts the surface-type air-lift reflux device applied for at the same time, which is mainly composed of a horizontal air inlet pipe 1, a closed suction pipe 2 connected horizontally and vertically, and a surrounding airtight airtight pipe located above the middle of the suction pipe. The box body 3, the air nozzle 4 located in the box body, the standpipe elbow 5, the return inclined pipe 6, and the return flow through the wall pipe 7 are composed, and are controlled by the compressed air control device 8 outside the pool.

[0028]The mud-water mixture from the biochemical treatment tank 10 enters ...

Embodiment 2

[0031] The sewage treatment capacity of a sewage treatment plant is 12,000 m 3 / d, there are 2 towers of 6000m each 3 / d V-type air-lifting integrated sewage treatment tank, the horizontal suspended sludge air-lifting and reflux method of the present invention is used to reflux the suspended activated sludge in the clarification area of the integrated treatment tank, and a total of 2 sets of surface-type air-lifting Micro power reflux device, each set consumes 0.995m of air 3 / min, the converted blower power consumption is 1.456Kw (single blower parameter Q=16.67 m 3 / min, P=58.8kPa, equipped with a 30kW motor with a frequency conversion device, the actual shaft power is 24. 4kW), and a good activated sludge return effect and sewage treatment effect have been obtained. The water quality is shown in the table below.

[0032] Sewage treatment plant design inlet and outlet water quality table

[0033] project COD BOD 5 SS TN NH 3 -N TP Influent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com