Precision tubular microporous aerator mounting and detecting system and method

A technology of microporous aerator and detection system, which is applied in chemical instruments and methods, water aeration, testing of machine/structural components, etc. Assembly error uncertainty and other problems, to achieve the effect of reliable performance, low price, and guaranteed cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

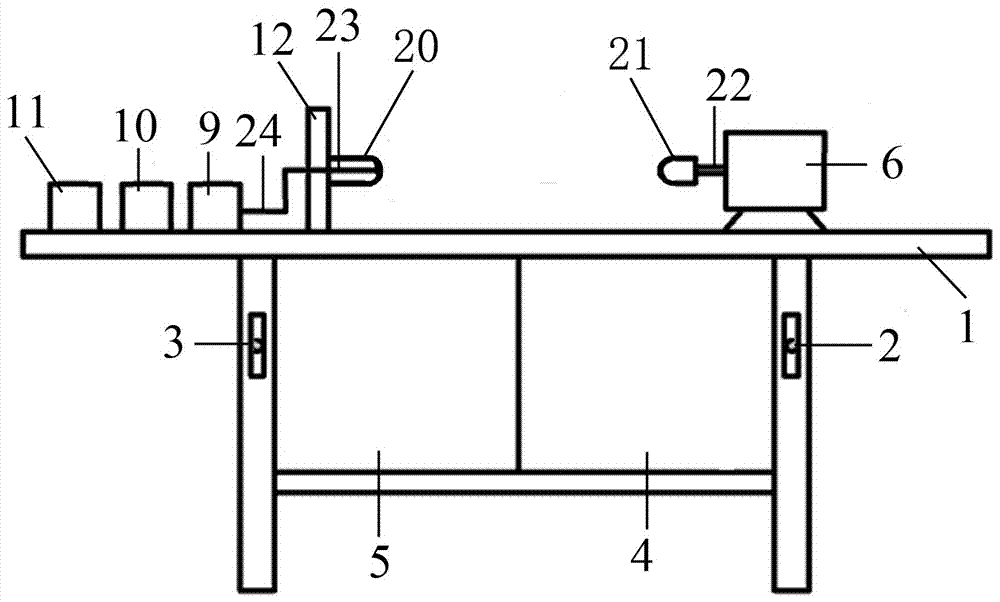

[0031] It consists of a workbench (1), installation facilities (4) and testing facilities (5). The installation facilities (4) and testing facilities (5) are set on the workbench (1). By installing the pneumatic switch (2) and the testing switch (3) Installation and testing of the conversion aeration diaphragm.

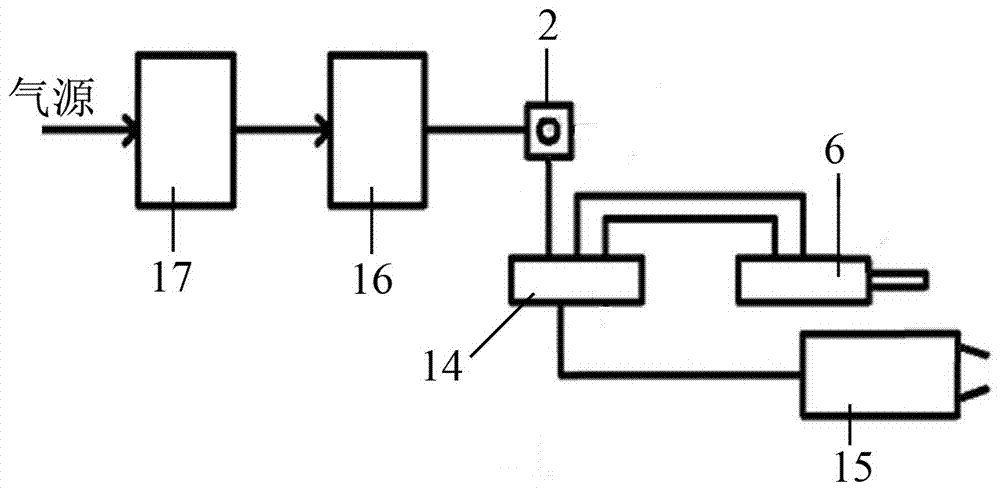

[0032] The installation facility (4) consists of installing pneumatic switches (2), cylinders (6), pneumatic valves (14), pneumatic clamps (15), filters (16) and pressure reducing valves (17), through air compressors or blowers The gas source is generated, and the gas source is connected to the pressure reducing valve (17) through the pipeline. The pressure reducing valve (17) is made of stainless steel. The pressure reducing valve (17) keeps the gas source stable and the work force consistent. ) to filter out impurities in the gas source and keep the gas source clean. The filter (16) adopts a film type pressure reducing valve, a pilot piston type gas pressure reducin...

Embodiment 2

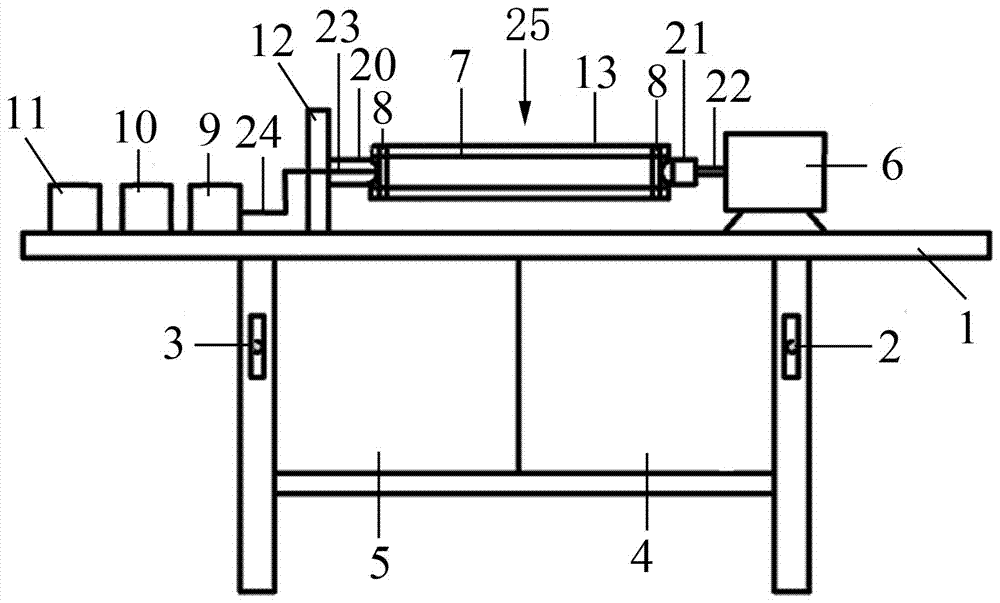

[0034] The pneumatic valve (14) is respectively connected with the cylinder (6) and the pneumatic clamp (15). The cylinder (6) complies with the international standard IS06430 and international standard 6431. The end of the push rod (22) of the cylinder (6) is set Movable plugging (21), one end of the aeration pipe (7) of the tubular microporous aerator (25) is installed at the end of the movable plugging (21), and the end of the movable plugging (21) is connected with the aeration The ends of the pipes (7) coincide, and the ends of the movable plugging (21) are tightly sealed to block the ends of the aeration pipes (7) of the tubular microporous aerator (25), and the pneumatic pliers (15) lock Close clamp (8), clamp (8) adopts single-ear stepless clamp.

[0035] The detection facility (5) consists of a detection switch (3), a gas flow meter (9), a time relay (18) and a solenoid valve (19). The power supply is connected to the detection switch (3) through a circuit, and the de...

Embodiment 3

[0037] The installation facility (4) and testing facility (5) are connected with the main controller (10). The main controller (10) adopts PC or industrial control machine. The installation facility (4) and testing facility (5) aerate the installation Tube (7) data information and detection data information of aeration tube (7) is transmitted to the main controller (10), and the main controller (10) collects data information, stores data information, sorts out each aeration tube (7) data information and analysis data information, and print out the data information of each aeration pipe (7) through the printer (11).

[0038] A gas flowmeter (9), a main controller (10), a printer (11), a support frame (12) and a cylinder (6) are fixedly arranged on the workbench (1), and the support frame (12) and the cylinder (6) are relatively installed. Located at both ends of the workbench (1), the other end of the workbench (1) is fixedly installed with a support frame (12), and a fixed blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com