A tire nut fastening device

A fastening device and nut technology, used in tire installation, tire parts, wheel assembly and disassembly equipment, etc., can solve the problems of low efficiency, inability to screw tire nuts, and difficulty in ensuring the same degree of nut screwing, so as to avoid repetition. Twisting, not easy to damage, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

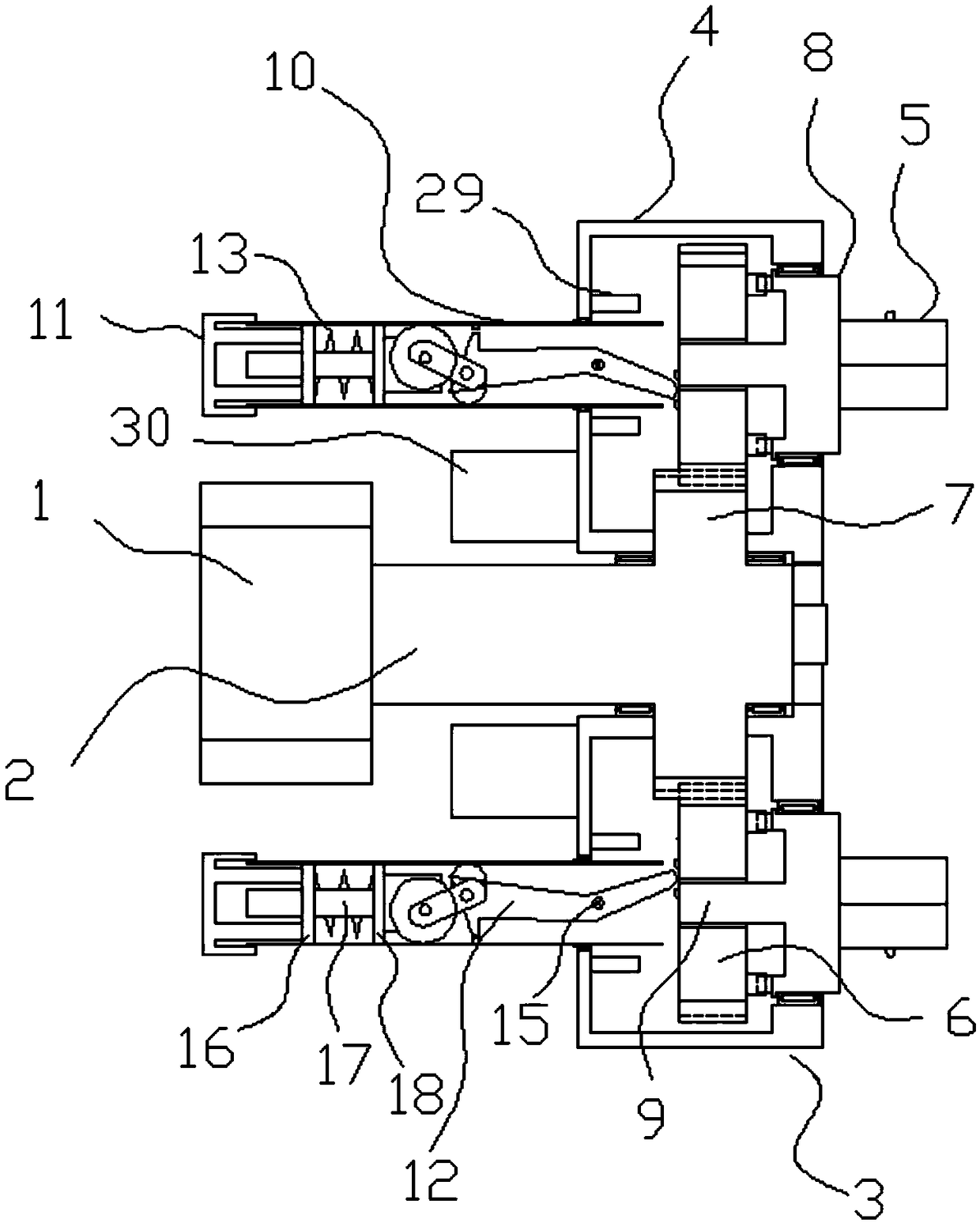

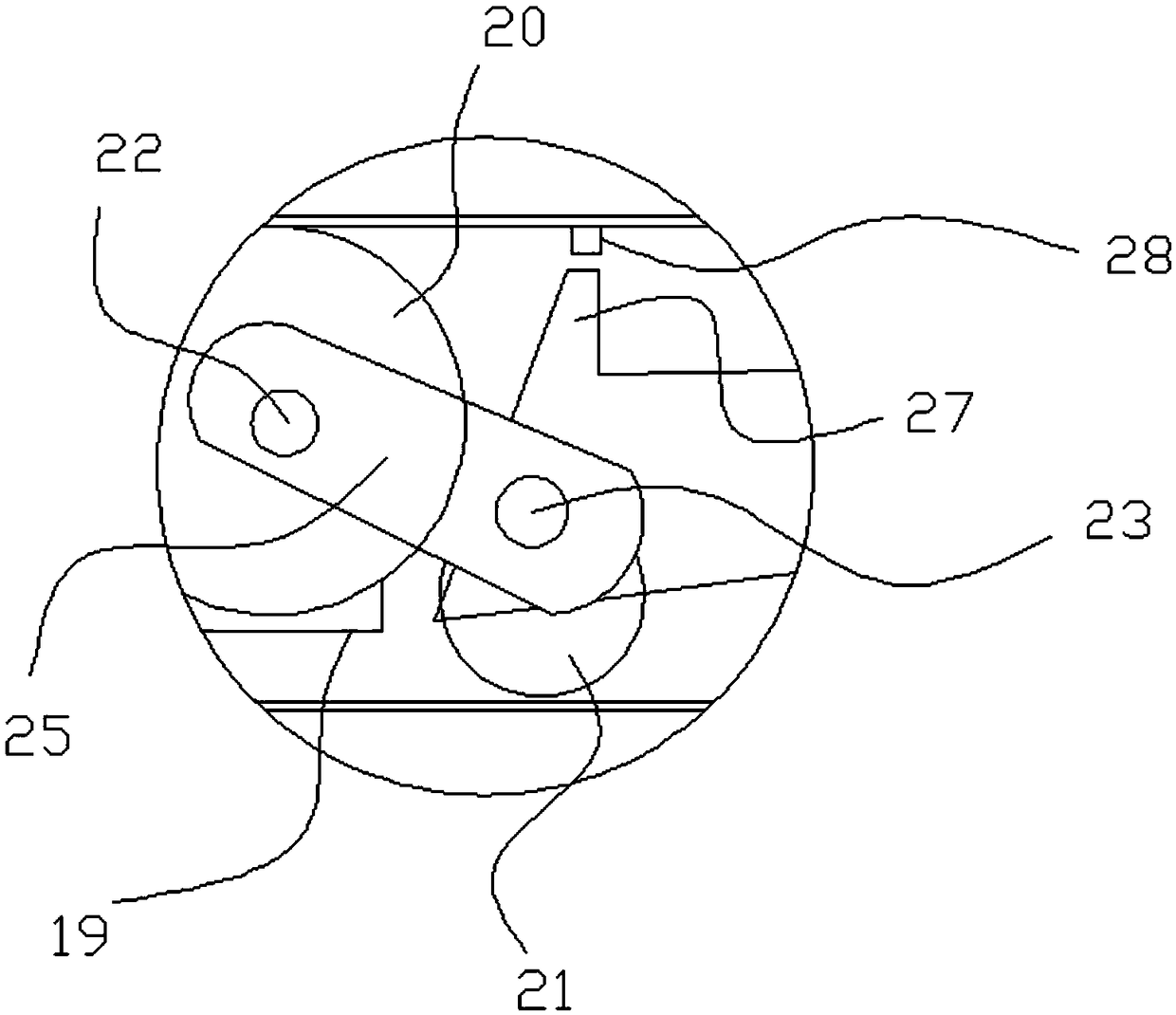

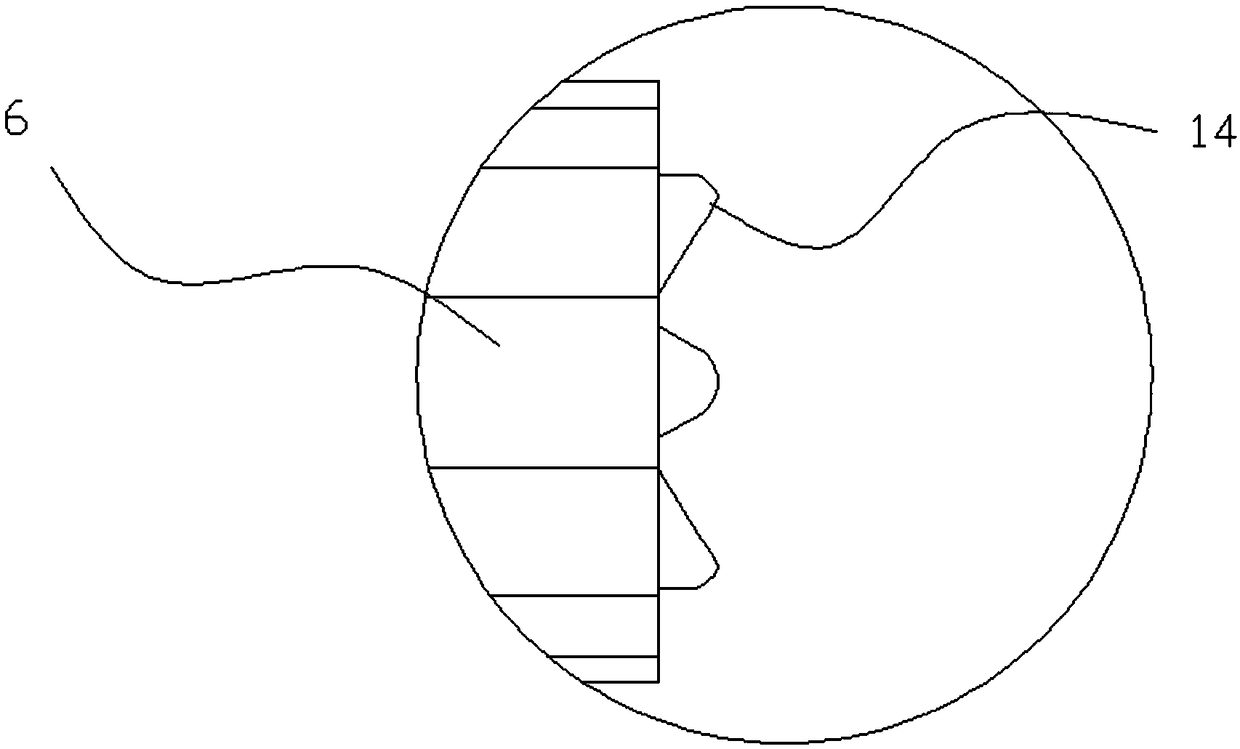

[0025] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 In the shown embodiment, a tire nut fastening device includes an air gun joint 1, a main shaft 2, and four driven parts 3, and the four driven parts are evenly distributed around the outside of the main shaft with the main shaft axis as the center line. The driven part includes a power frame 4, a sleeve joint 5 for fastening tire nuts, a driven gear 6 for driving the sleeve joint to rotate, the driven gear is in the power frame, and the power The frame is provided with a sleeve bearing, and the sleeve joint is connected with the sleeve bearing. The main shaft is provided with a driving gear 7 coaxial with the main shaft, and the driving gear meshes with each driven gear.

[0026] When it is necessary to fasten the tire nuts on the tire, you can put the four tire nuts on one tire into the sleeve joint respectively (this sleeve joint is directly matched with the tire nut, and if the tire nut need...

Embodiment 2

[0035] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as Figure 6 , Figure 7 As shown in , the driven gear and the sleeve joint no longer have structures such as ratchets and tooth grooves, but adopt the structure of driving ball 31 and driving groove 32, as follows: figure 2 As shown in , the power frame is provided with an adjustment cylinder coaxial with the driven gear, one end of the adjustment cylinder extends into the power frame, and one end of the adjustment cylinder is provided with an adjustment pressure screw threaded with the adjustment cylinder. The other end of the adjustment cylinder is facing the driven gear. The adjustment cylinder is provided with an adjustment push rod. A spring is arranged between one end of the adjustment push rod and the adjustment pressure head. The other end of the adjustment push rod contacts the driven gear. One end face, the other end face of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com