A cylinder assembly machine

A technology of assembling machines and oil cylinders, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., to achieve the effect of high safety guarantee, reasonable structure design, and avoidance of safety risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

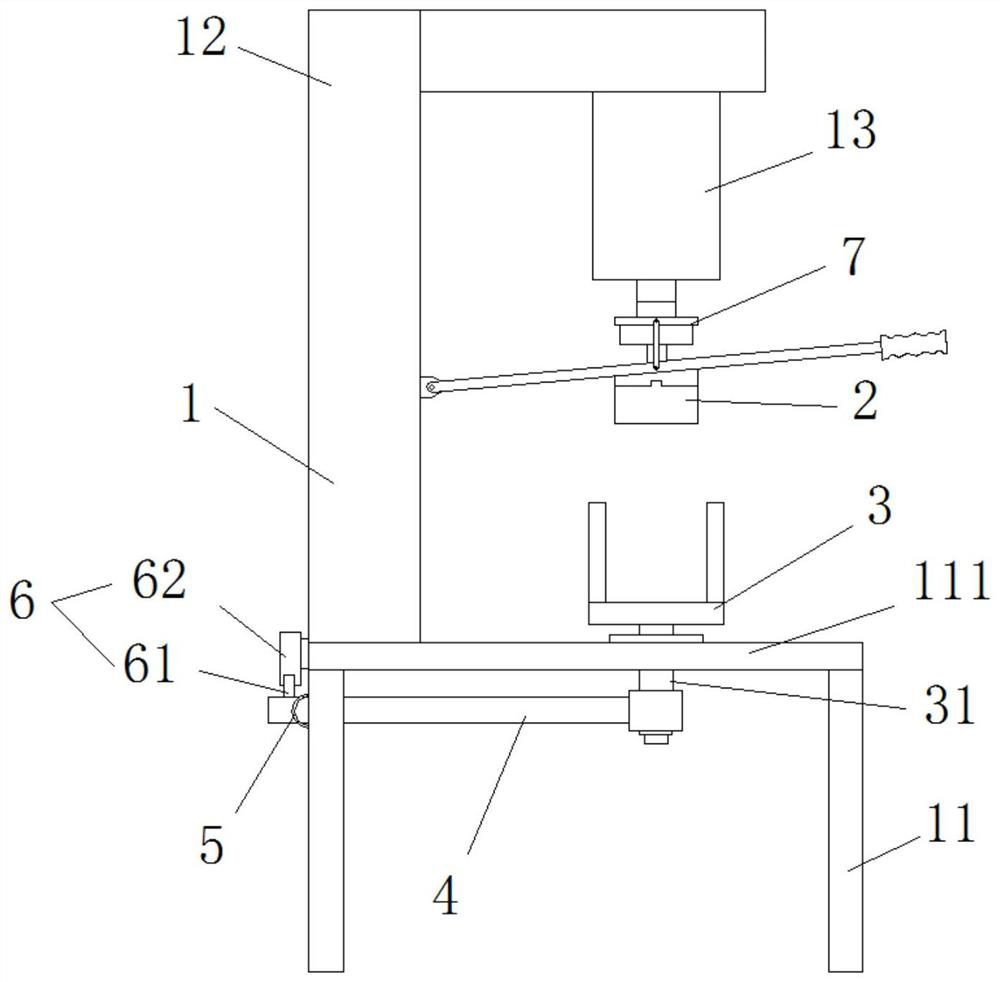

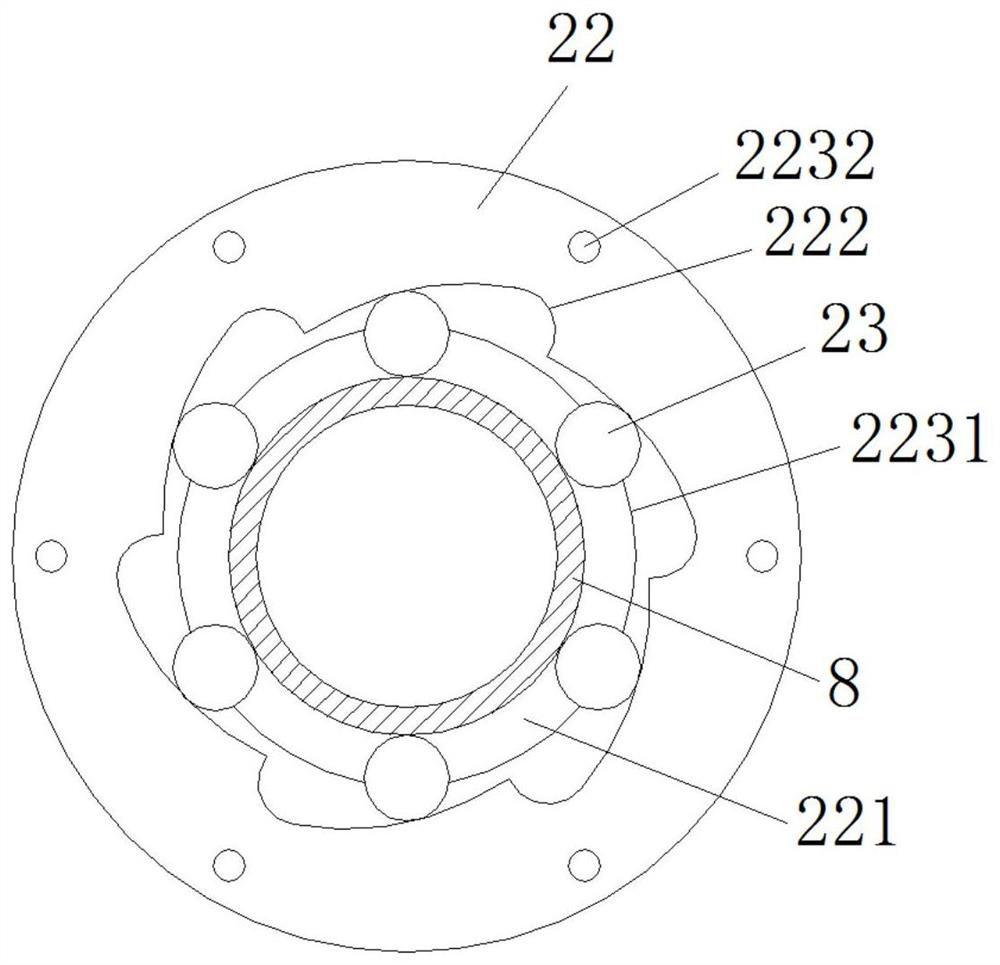

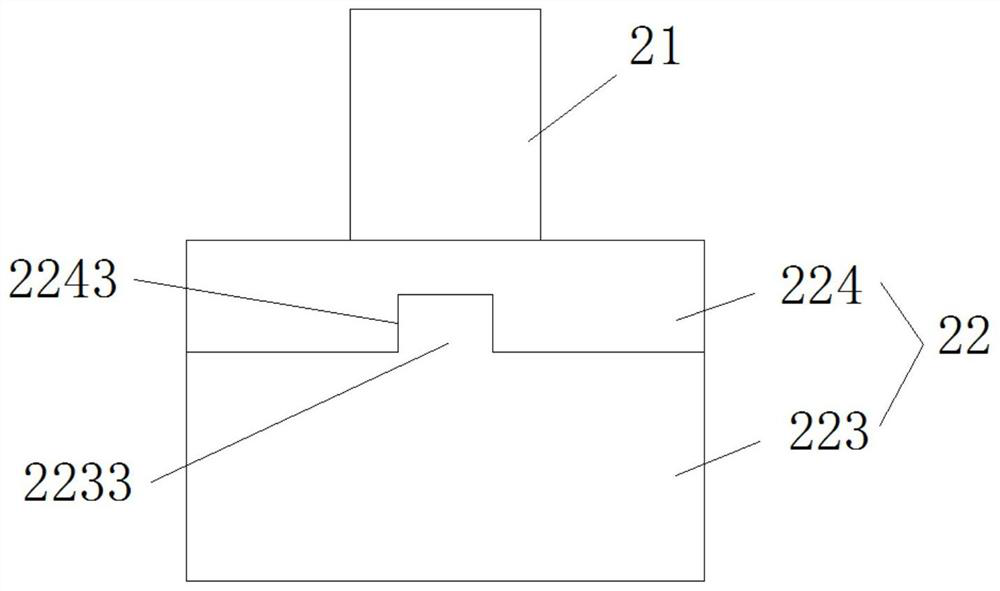

[0034] In order to make the technical means, the creation characteristics, the purpose and efficacy of the present invention are readily understood, and the following examples are incorporated figure 1 Adherent Figure 8 The technical scheme provided by the present invention will be specifically described, but the following is not limited as the present invention.

[0035] figure 1 A structural diagram of an embodiment of a cylinder assembly of the present invention. like figure 1 As shown, the cylinder assembly provided by the present embodiment includes: the frame 1, the spindle 13, the clamping device 2, the casing 3, the pendulum 4, the spring 5, the trigger switch 6, and the controller, the frame 1 is the spindle 13, The clamping device 2, the casing 3, the pendulor 4, the spring 5, the trigger switch 6, and the arrangement of the controller provide the mounting basis, and is rotated and rifleled by the spindle 13 and the clamping device 2. The cylinder holder is attached to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com