A device for assembling high-pressure oil rail sealing joints

A technology of sealing joints and high-pressure oil, which is applied to hand-held tools and manufacturing tools, can solve problems such as low efficiency, affecting product use, and difficulty in ensuring consistent tightening degrees, and achieves sensitive and fast adjustment, good reliability, and guaranteed quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

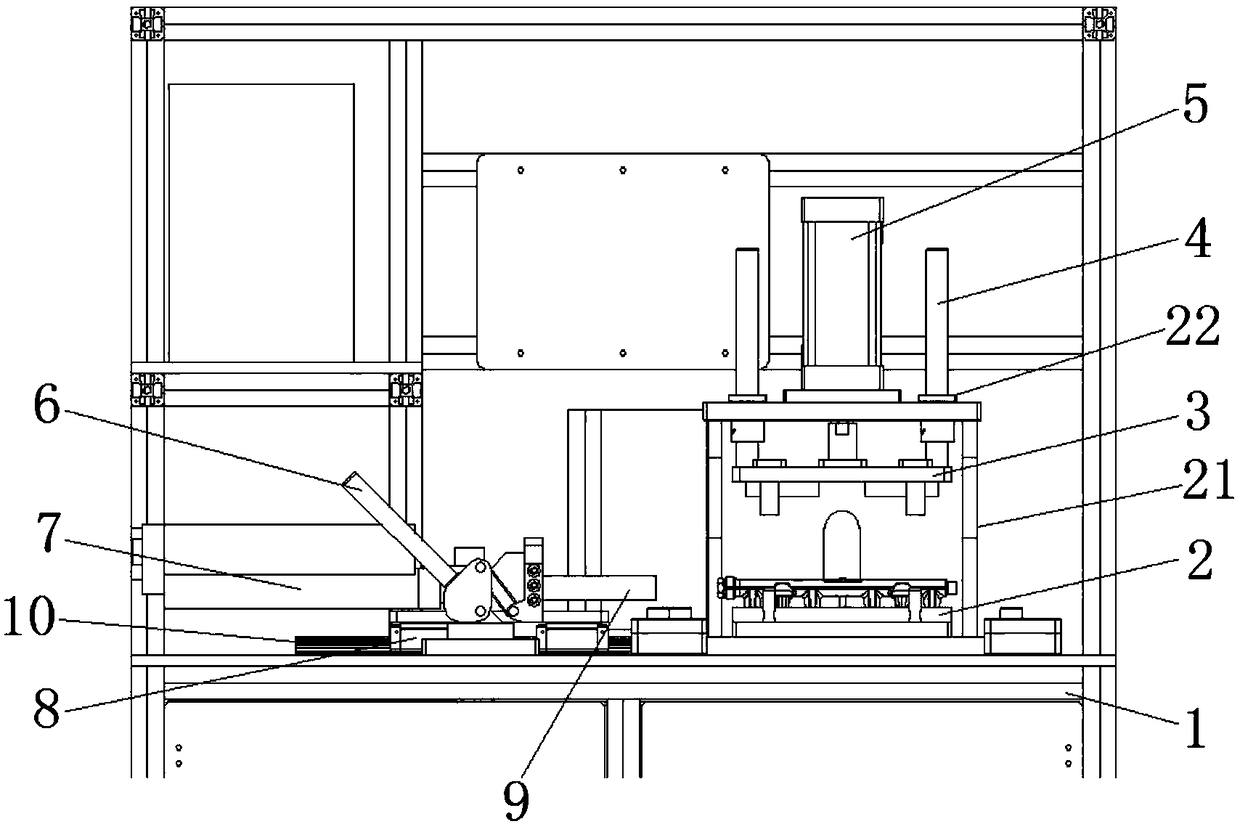

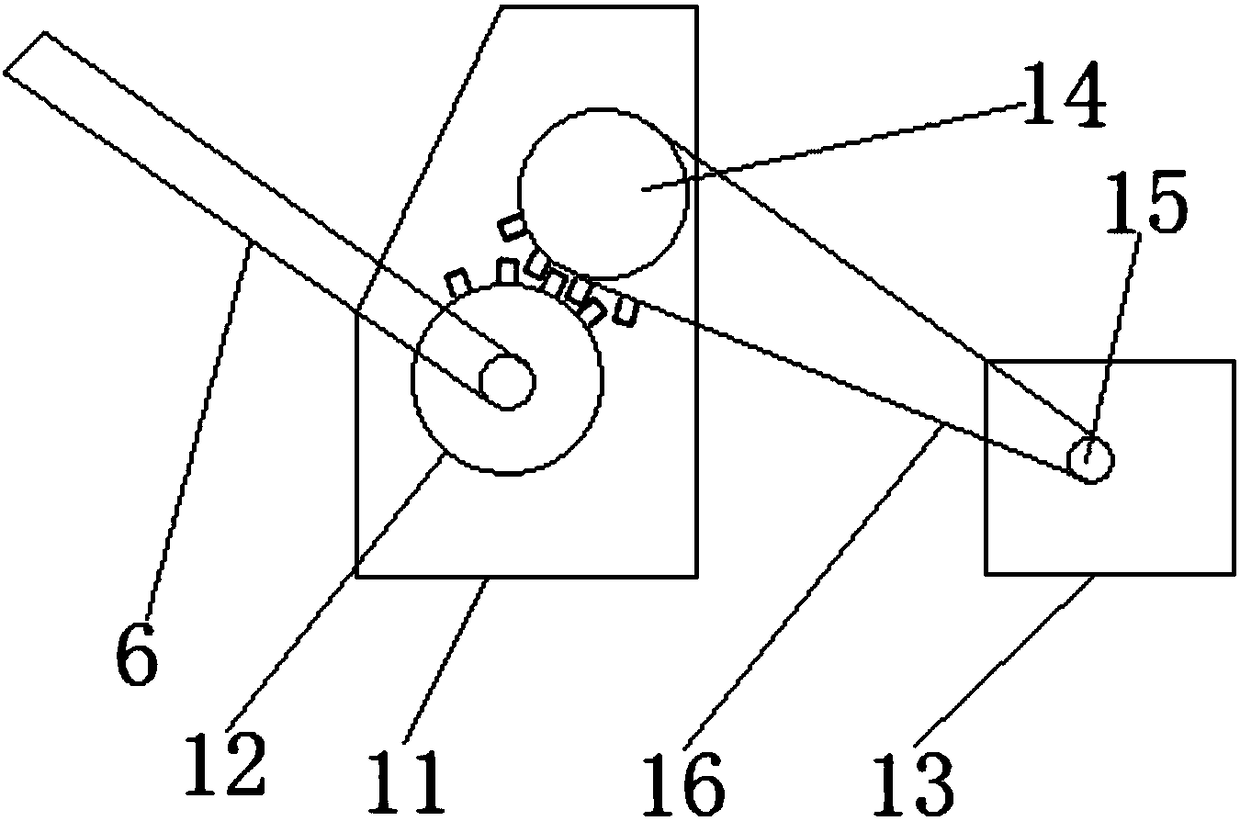

[0032] Such as figure 1 Shown is a device for assembling high-pressure oil rail seal joints, which includes a workbench 1, a slide rail 10 set on the workbench 1, a seal joint tightening mechanism slidably set on the slide rail 10, and a sealing joint The high-pressure oil rail clamping mechanism that is compatible with the joint tightening mechanism, places the high-pressure oil rail with a sealed joint at one end in the high-pressure oil rail clamping mechanism, and adjusts the position of the sealed joint tightening mechanism on the slide rail 10, Afterwards, the sealing joint tightening mechanism tightens and assembles the sealing joint on one end of the high-pressure oil rail.

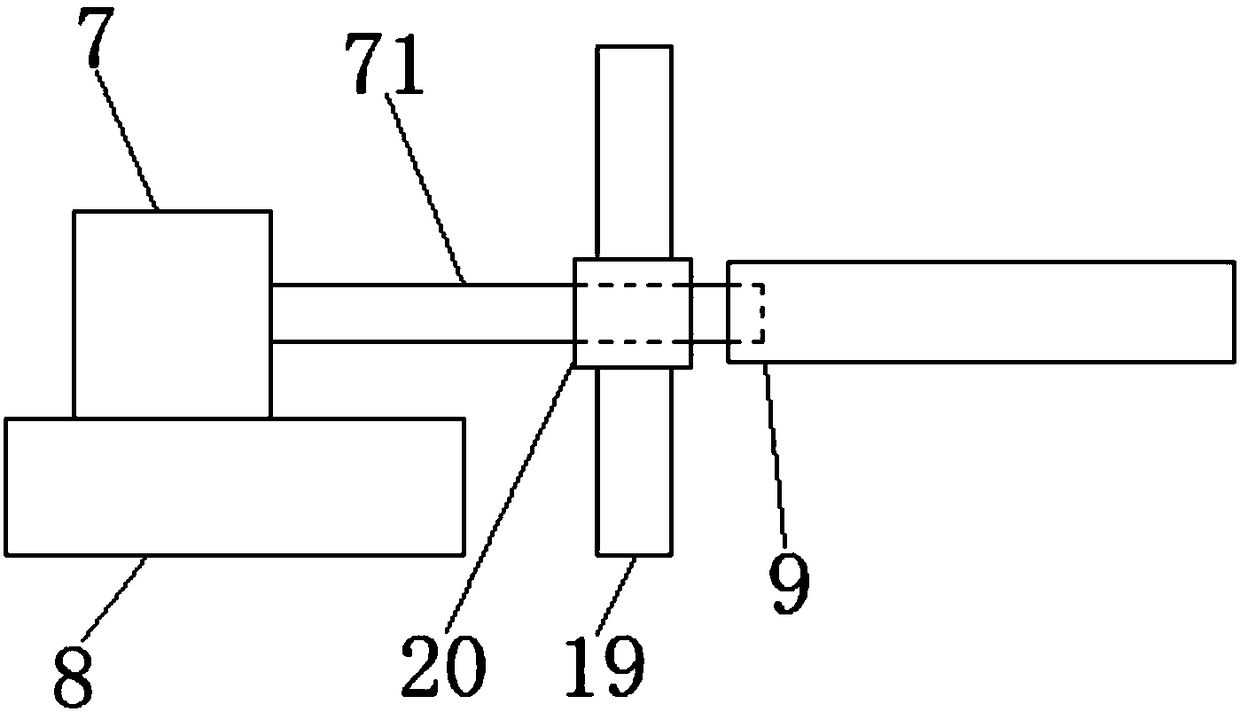

[0033] Such as figure 2 As shown, the sealing joint tightening mechanism includes a slider 8 slidably arranged on the slide rail 10 and a torque meter 7 arranged on the slider 8, the torque meter 7 is provided with an output shaft 71, and one end of the output shaft 71 is covered with A sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com