Patents

Literature

36results about How to "Solve the problem of meeting emission standards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

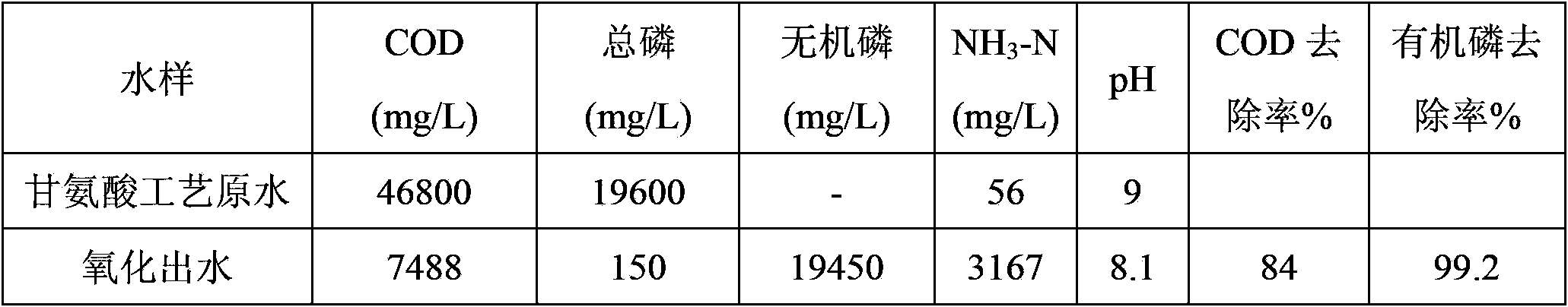

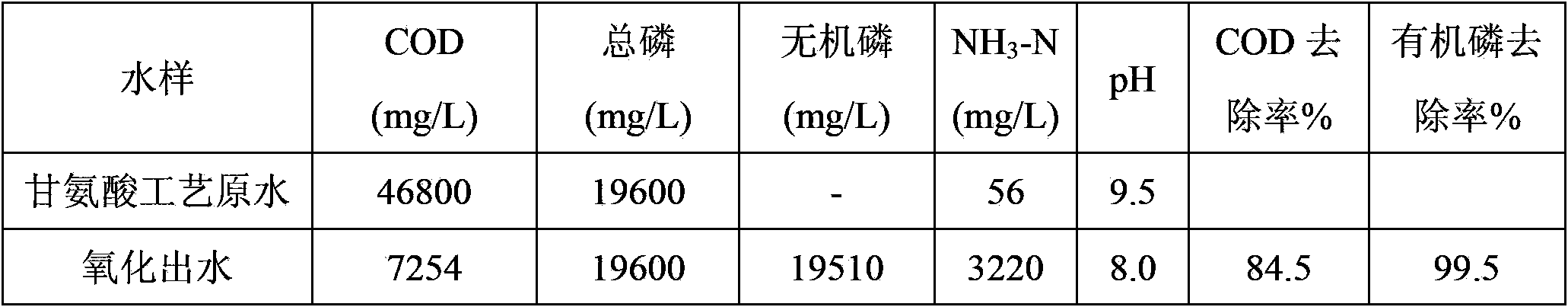

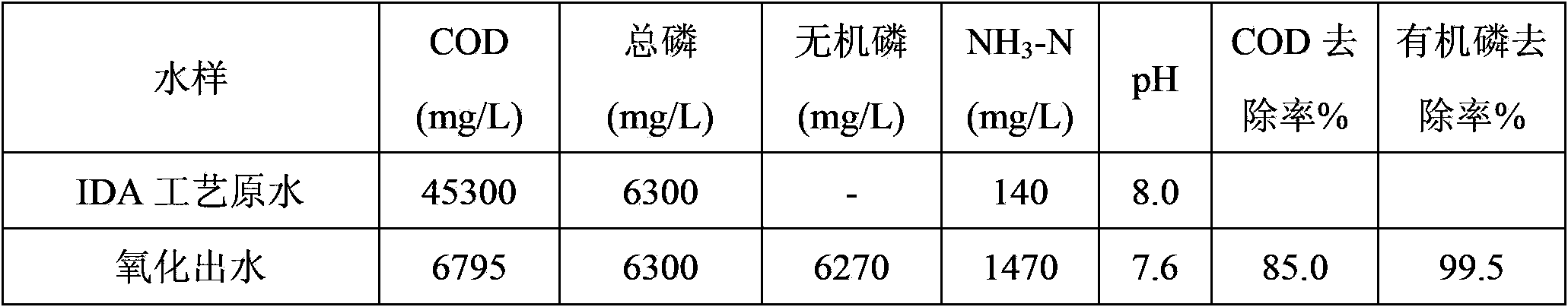

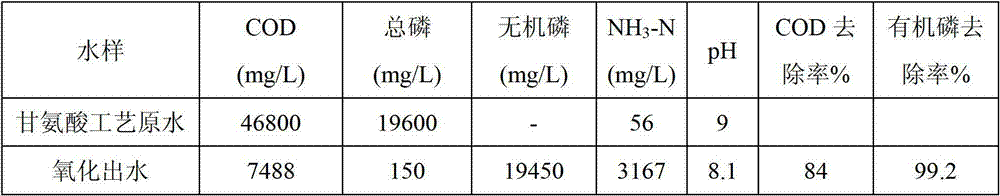

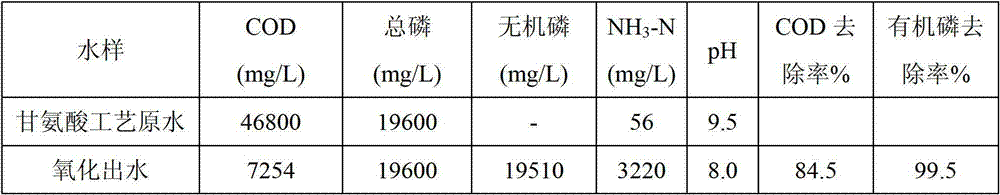

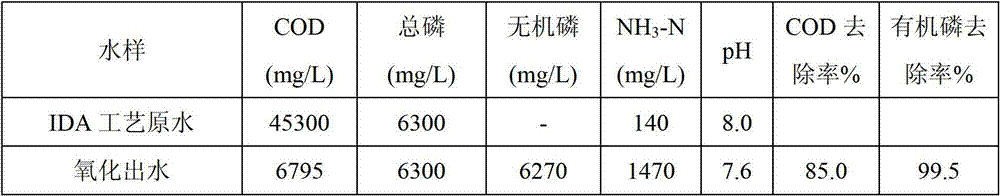

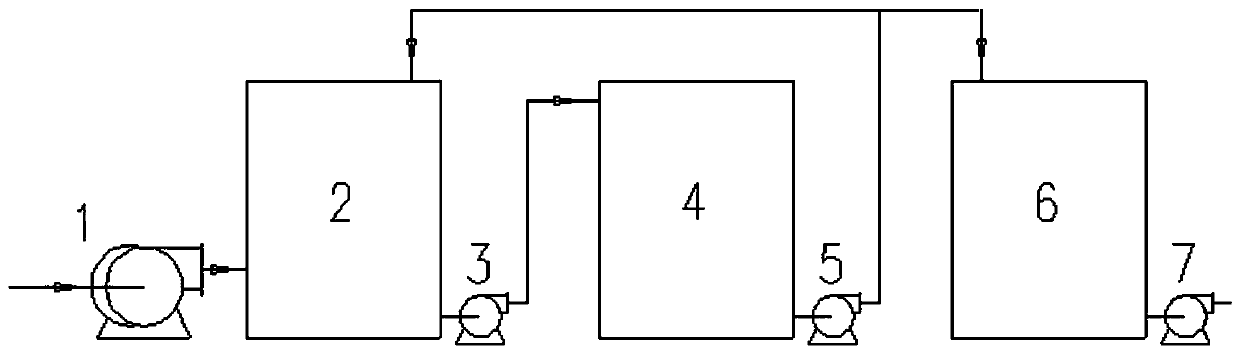

Catalytic wet oxidation pretreatment method of glyphosate production wastewater

ActiveCN103663667AHigh activityReduce dosageMultistage water/sewage treatmentWater/sewage treatment by oxidationPretreatment methodChemical oxygen demand

The invention relates to a catalytic wet oxidation pretreatment method of glyphosate production wastewater, comprises the following steps: firstly regulating pH value to be more than 8 and less than 10, adding a multi-component homogeneous catalyst and carrying out oxidative degradation on pollutants in wastewater for 0.3-2 hours by using a continuous catalytic wet oxidation device with air as an oxidizing agent at the reaction temperature of 210-230 DEG.C and the reaction pressure of 2-4MPa, wherein the catalyst is a soluble transition metal salt mixture. By adopting the method for treating the glyphosate production wastewater, the organic phosphorus conversion rate is high, the COD (chemical oxygen demand) removal rate is high, the biodegradability of the wastewater can be improved, and the secondary pollution is avoided. The method has the advantages that the catalyst activity is high, low in cost and easy to get, reaction conditions are relatively mild, and continuous operation is easily implemented; the glyphosate production wastewater can be discharged in standard through the combined process of catalytic wet oxidation pretreatment-routine technical dephosphorization and deamination-biochemistry, and the industrialized application prospect is great.

Owner:中国中化股份有限公司 +2

Integration treatment recovery method for alkali decrement waste water by film method

InactiveCN101148298AReduce the amount of acid addedLow costWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentRecovery methodLiquid waste

The present invention discloses integrated membrane process of treating waste water from alkali weight reducing process includes flocculating, pre-filtering to eliminate particles larger than 10 micron, ultrafiltering and discharging ultrafiltered concentrated liquid, nanometer filtering the ultrafiltered filtrate in a nanometer filtering membrane assembly to obtain nanometer filtered filtrate accounting for 80-90 vol% and nanometer filtered concentrated solution accounting for 10-20 vol%, adding concentrated sulfuric acid solution to the nanometer filtered concentrated solution to regulate pH value to 2-3 to separate out terephthalic acid, and filtering out terephthalic acid before post-treatment. The present invention has the advantages of recovering and reusing most of NaOH in the waste water, recovering and reusing 80-90 % of water resource, reduced acid adding amount, and lowered cost.

Owner:ZHEJIANG UNIV

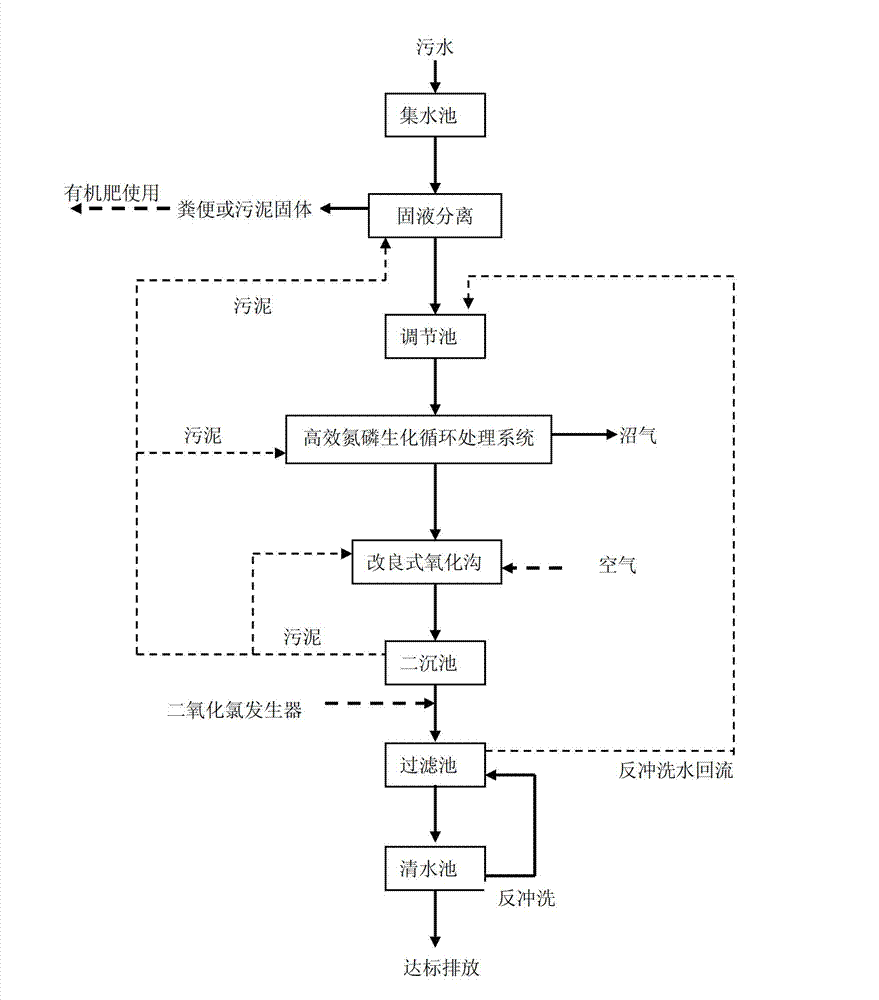

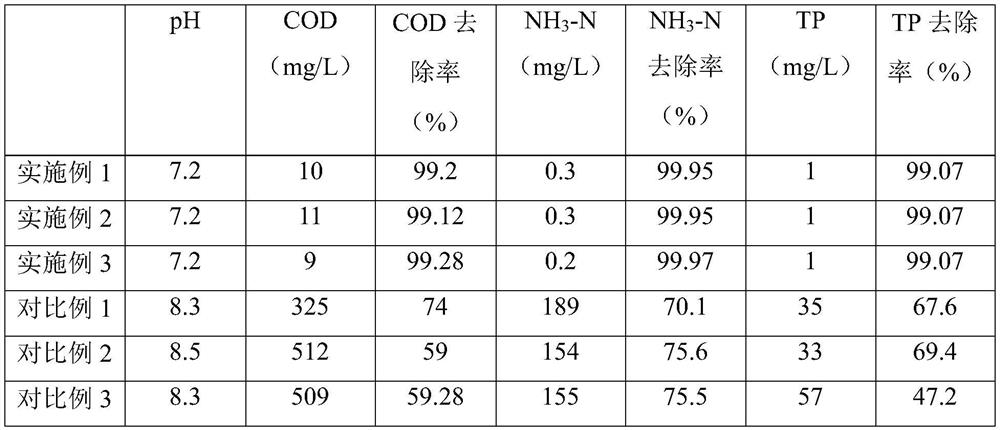

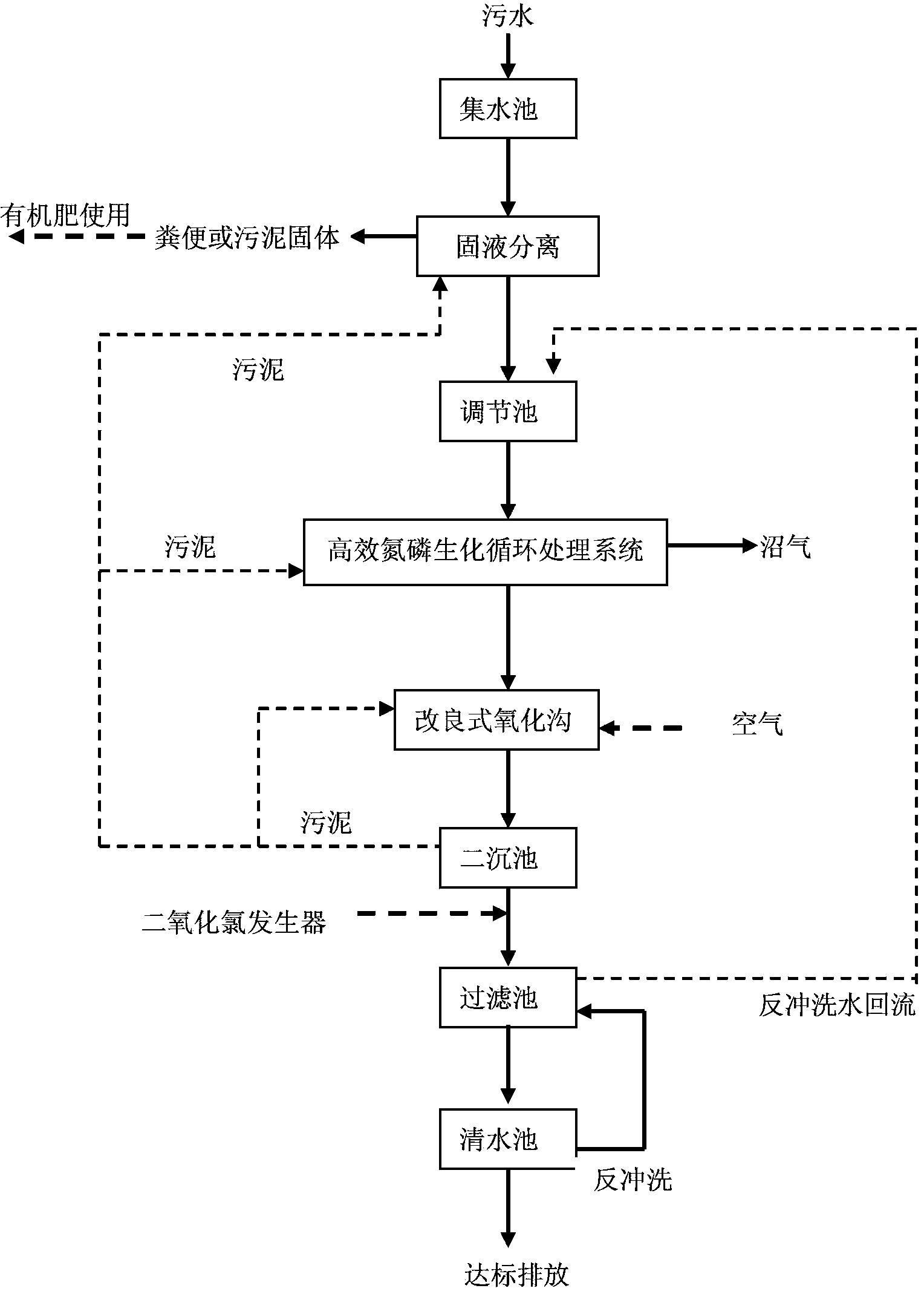

Method for treating livestock and poultry breeding waste water

InactiveCN102807302AAvoid inhibitionSufficient alkalinityBio-organic fraction processingClimate change adaptationChemical oxygen demandFiltration

The invention provides a method for treating livestock and poultry breeding waste water. The method mainly comprises the following steps of solid-liquid separation treatment, efficient nitrogen-phosphorus biochemical circulation treatment, modified oxidation ditch treatment, sludge reflux treatment, filtration and sterilization treatment and the like. The invention aims to provide the method for treating the livestock and poultry breeding waste water, which is high in capability of removing ammonia nitrogen, total nitrogen and total phosphorus and low in investment cost and running cost, and is easier to manage. The waste water treated by adopting the method provided by the invention can meet the requirement of the national Discharge standard of water pollutants for livestock and poultry breeding GB18596-2001; not only can the up-to-standard discharge requirement in the waste water treatment of the livestock and poultry breeding industry be effectively met, but also the difficult problem of removing the ammonia nitrogen while an organic matter is degraded is also solved; and the method is suitable for the waste water treatment of breeding farms on different breeding scales, similarly, is also suitable for the treatment of municipal domestic waste water and waste water with a high COD (chemical oxygen demand) or high ammonia nitrogen characteristic, and is wide in application prospect.

Owner:南宁绿智环保科技有限公司

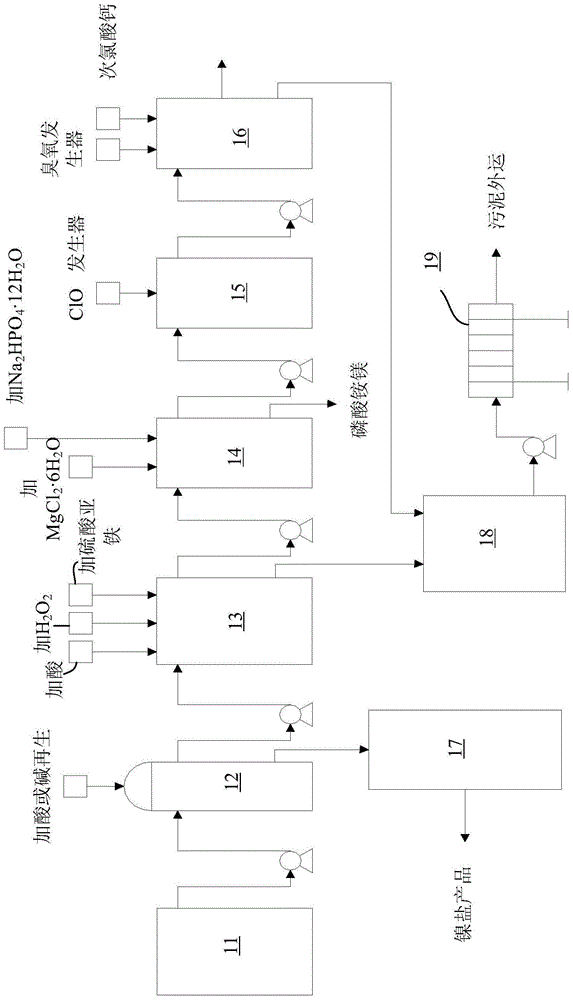

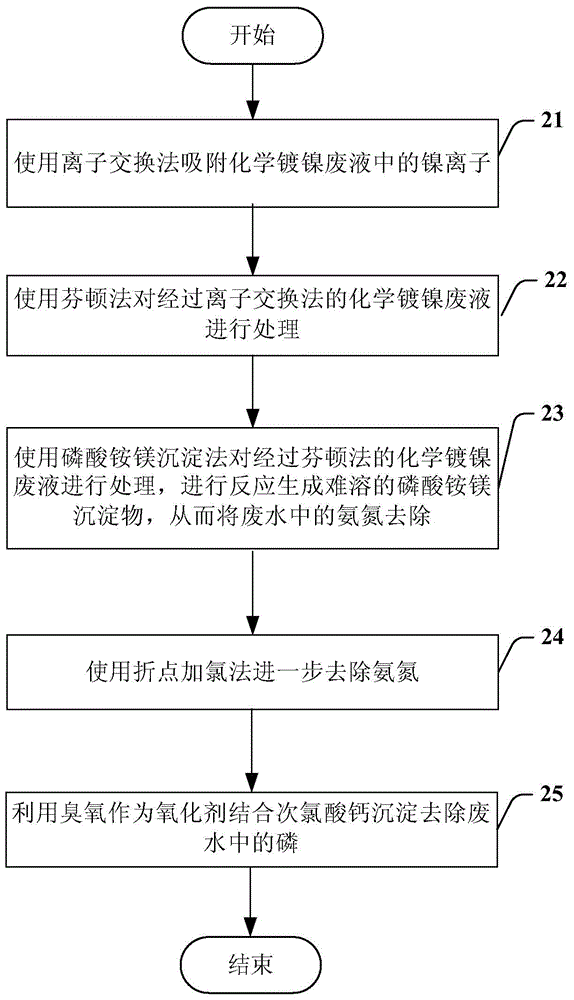

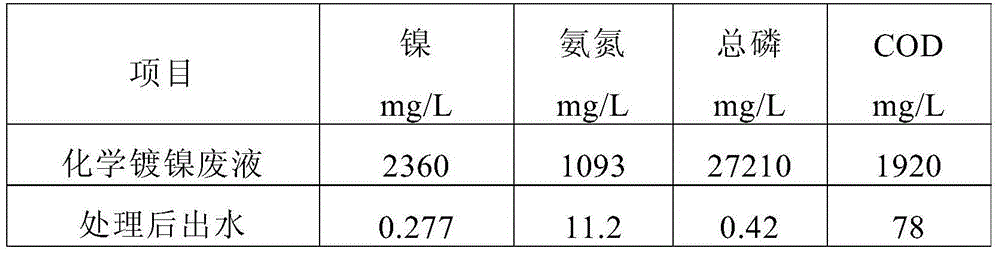

Method and equipment for standards-reaching treatment of chemical nickel plating waste liquid

PendingCN105800822ASolve the problem of meeting emission standardsWaste water treatment from metallurgical processMultistage water/sewage treatmentPhosphateFree form

The invention relates to a method and equipment for standards-reaching treatment of chemical nickel plating waste liquid. The method comprises the steps: adsorbing nickel ions from the chemical nickel plating waste liquid by using an ion exchange method; treating the chemical nickel plating waste liquid subjected to the ion exchange method treatment by using a Fenton method so as to carry out oxygenolysis on part of organic pollutants in wastewater, achieve an oxidated decomplexing effect and convert complex-form metal nickel ions into free-form nickel ions, meanwhile, oxidating organic substances in the waste liquid, destroying carbon chain structures of the organic substances, finally converting the organic substances into carbon dioxide and water, and lowering the COD of the wastewater; treating the chemical nickel plating waste liquid subjected to the Fenton method treatment by using an ammoniomagnesium phosphate precipitation method, carrying out a reaction so as to produce indissoluble ammoniomagnesium phosphate precipitates, thereby removing ammonia nitrogen from the wastewater; carrying out further ammonia nitrogen removal by using a break-point chlorination method; and removing phosphorus from the wastewater by using ozone as an oxidant and calcium hypochlorite precipitation. According to the method and equipment for the standards-reaching treatment of the chemical nickel plating waste liquid, disclosed by the invention, the standards-reaching emission of nickel, phosphorus, COD and ammonia nitrogen can be simultaneously achieved.

Owner:SHANGHAI LIGHT IND RES INST

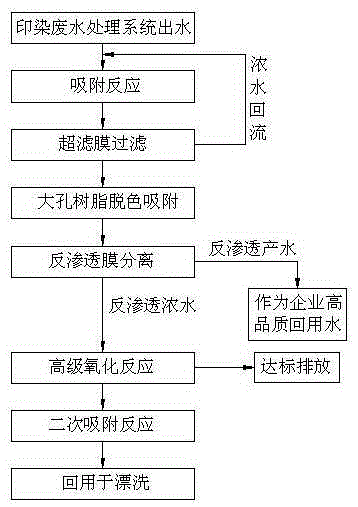

Reverse osmosis membrane treating and recycling method for printing and dyeing wastewater

InactiveCN105417775ASolve the problem of meeting emission standardsImprove reuse rateWater treatment parameter controlWater treatment compoundsUltrafiltrationChemistry

The invention discloses a reverse osmosis membrane treating and recycling method for printing and dyeing wastewater. According to the method, adsorption, ultrafiltration membrane filtration, macroporous resin adsorption and reverse osmosis membrane separation are conducted on water discharged from a printing and dyeing wastewater treatment system, reverse osmosis membrane produced water is taken as high-quality water to be used by enterprises for cyclic utilization, and after advanced oxidation reaction, part of reverse osmosis membrane concentrated water is for up-to-standard release and the other part is adsorbed and then reused for rinsing. The method has the advantages that deep wastewater treatment for up-to-standard release and reusing are combined organically, the total reuse rate of printing and dyeing wastewater is over 80%, the problem of up-to-standard release of wastewater is solved, and cost is reduced greatly due to the remarkable increase of the water reuse rate; part of reverse osmosis membrane concentrated water is for up-to-standard release and the other part is reused after being treated, saltness of wastewater tends to be a stable value gradually and does not increase any more, and crash of a biological treatment system caused by non-stop increase of saltness is effectively avoided.

Owner:NINGBO QINGSHUIYUAN WATER TECH

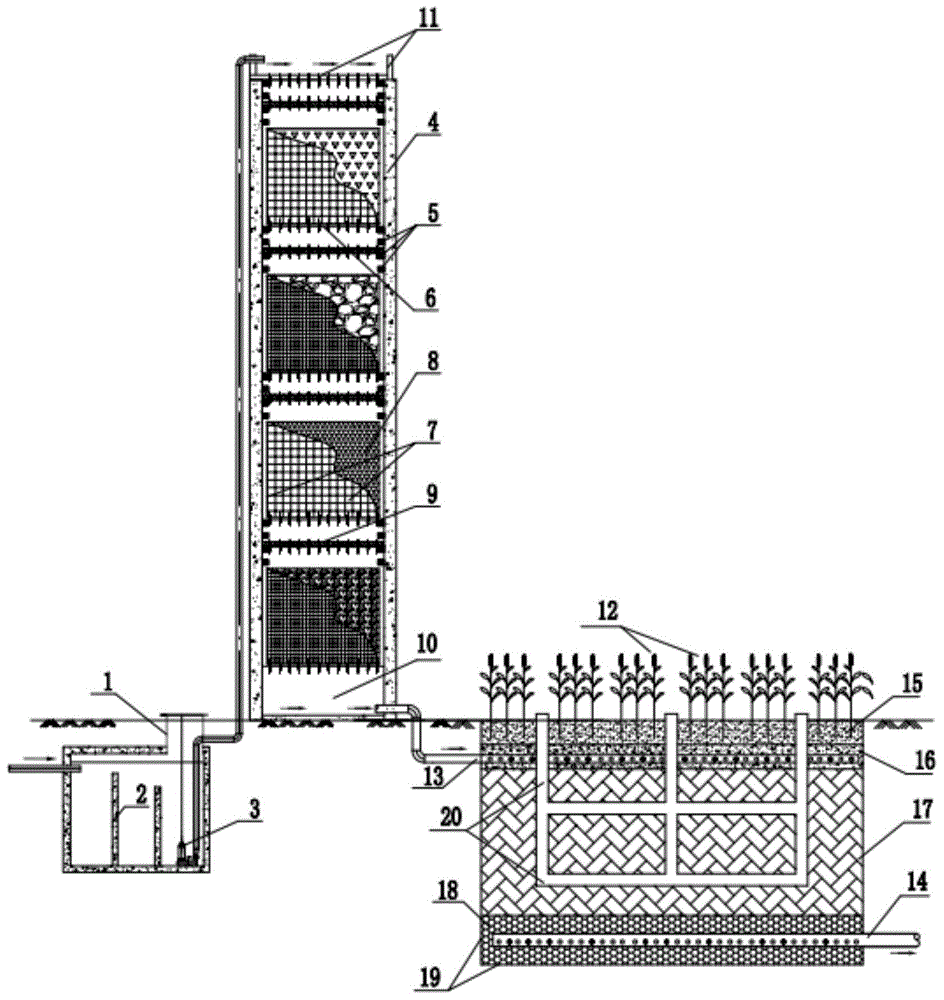

Multi-medium biological-ecological cooperative treatment system and multi-medium biological-ecological cooperative treatment method for sewage in highway affiliated facilities

ActiveCN104085990AAdjustable structureImprove utilization efficiencyTreatment with aerobic and anaerobic processesConstructed wetlandSludge

The invention discloses a multi-medium biological-ecological cooperative treatment system and a multi-medium biological-ecological cooperative treatment method for sewage in highway affiliated facilities. The system comprises a multi-medium fixed biological bed and a multi-medium tidal flow ecological wetland. The treatment method of the system comprises the following steps: lifting sewage to enter the multi-medium fixed biological bed by virtue of a lift pump, under a micro-power ventilation condition, effectively degrading an organic substance and ammonia nitrogen by virtue of the multi-medium fixed biological bed, enabling the effluent from the multi-medium fixed biological bed to enter the tidal flow artificial wetland to further remove total nitrogen and total phosphorus. The method disclosed by the invention has the advantages that the multi-medium fixed biological bed and the tidal flow artificial wetland are organically combined and respective functional advantages are played to achieve the purposes that the organic substance, ammonia nitrogen, total nitrogen and total phosphorus in the sewage are efficiently removed simultaneously. The system has the advantages of low investment, low running cost, low maintenance and unattended operation, basically no residual sludge is produced and the deep nitrogen and phosphorus removal and recycling of sewage in highway ancillary facilities can be achieved.

Owner:CHINA ACAD OF TRANSPORTATION SCI +1

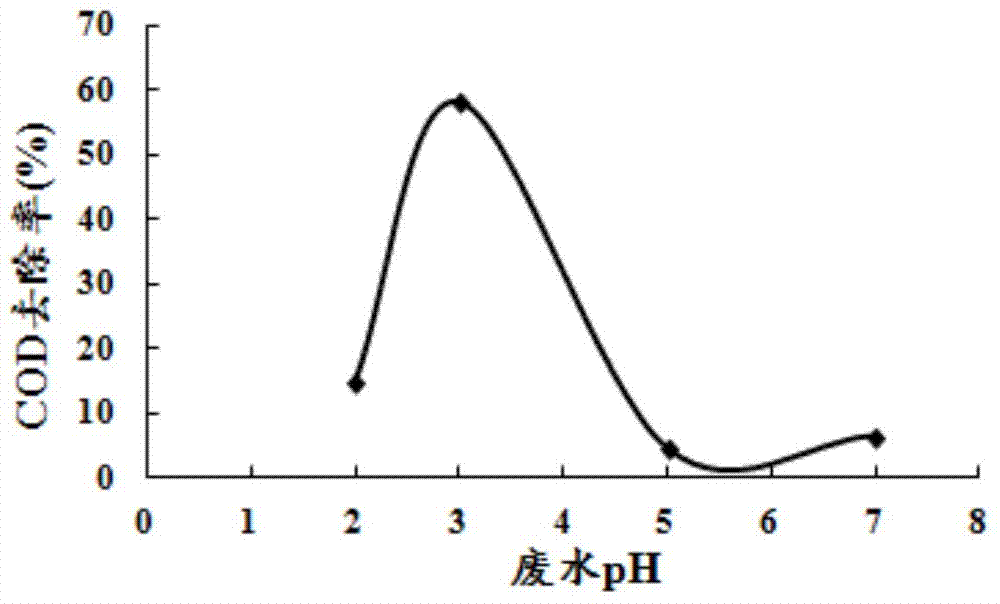

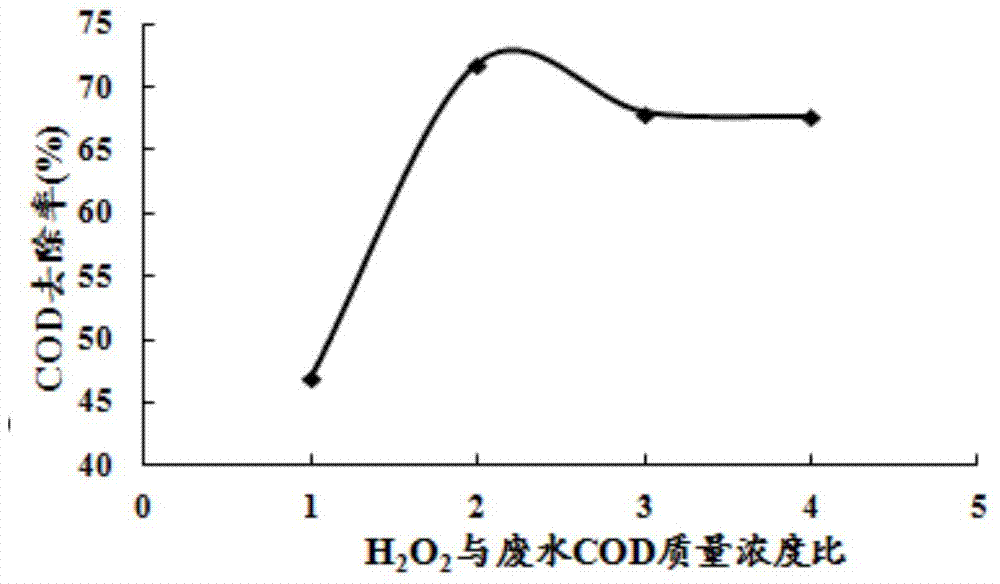

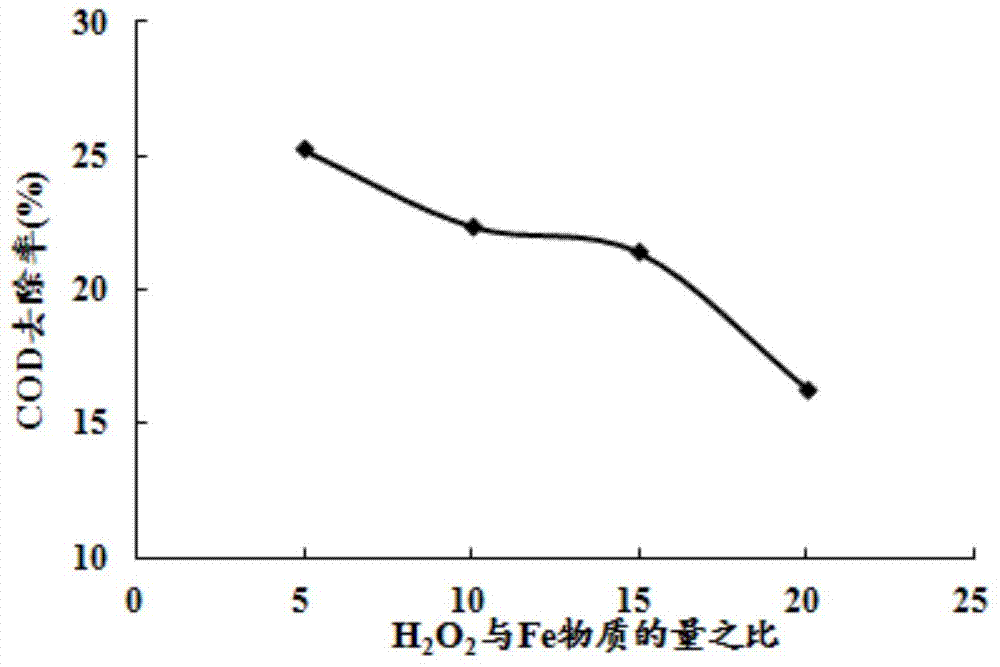

Treatment method of high-salt content and refractory oil exploitation wastewater

InactiveCN103755064ASolve the problem of meeting emission standardsImprove oxidation efficiencyMultistage water/sewage treatmentSuspended particlesParticulates

The invention discloses a method for treating high-salt content and refractory oil exploitation wastewater, which specifically comprises the following steps of acidifying the high-salt content, high-oil content and refractory oil exploitation wastewater treated by a natural settling coarse graining efficient coalescence separation process, an air floatation process and a coagulating settling process by using an acid material, and adjusting the pH value of the beneficiation wastewater; sequentially adding a proper amount of proper ferrous sulfate and a small amount of hydrogen peroxide to form an efficient oxidant Fenton reagent; neutralizing with an alkaline material; separating the floc with a sedimentation tank; finally, reducing the content of the COD (chemical oxygen demand) in the wastewater through active carbon adsorption. The treated wastewater reaches the national standard of Integrated Wastewater Discharge Standard of Liaoning (DB21 / 1627-2008). With simple processes, the method disclosed by the invention can remove the suspended particles and organic matters left in the wastewater, needs relatively small equipment and space, and can better solve the problem in deep purification of the high-salt content and refractory oil exploitation wastewater.

Owner:TIANJIN ECOLOGY CITY ENVIRONMENTAL PROTECTION

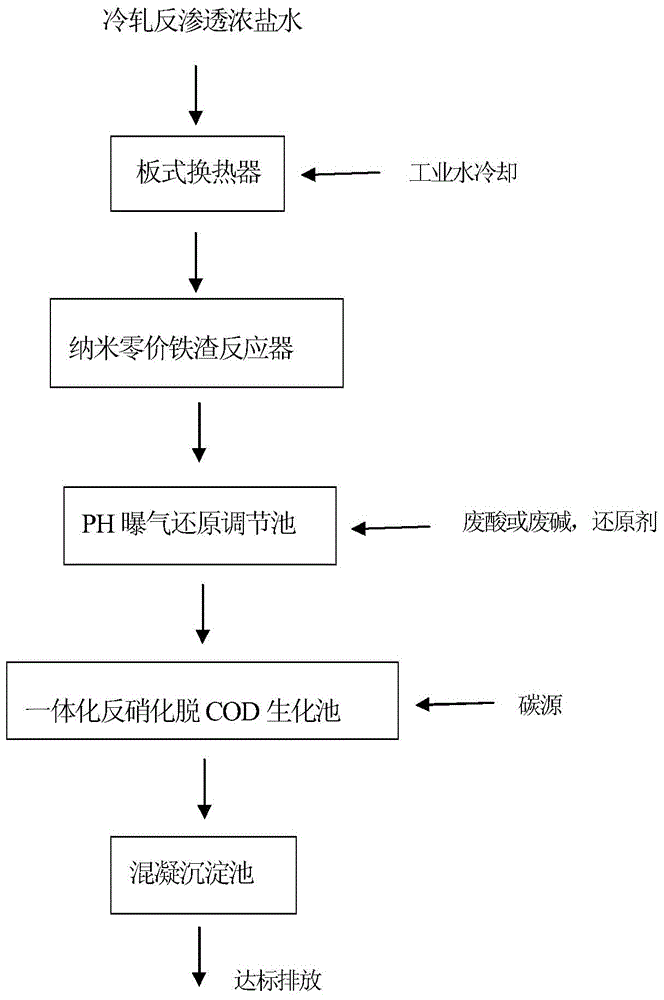

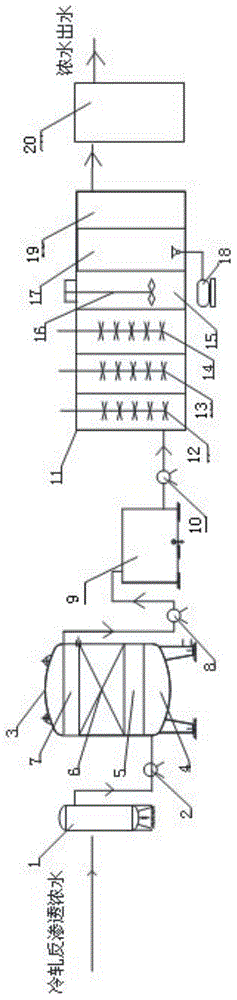

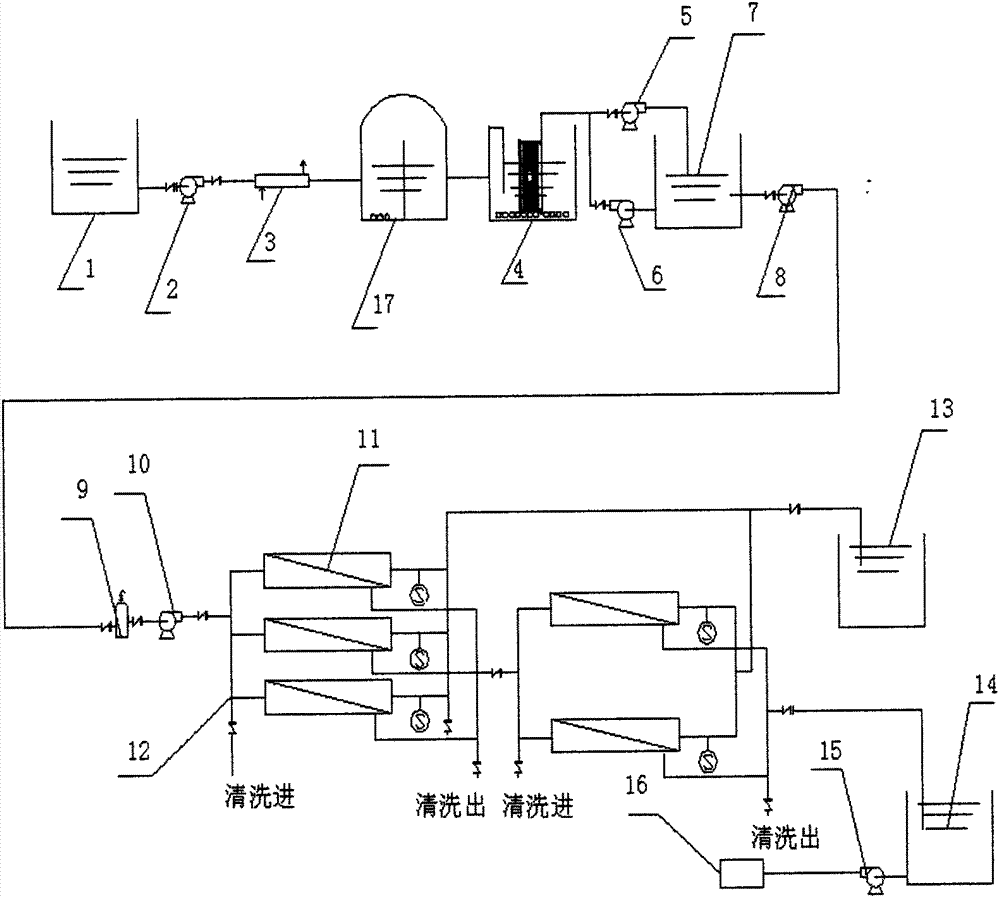

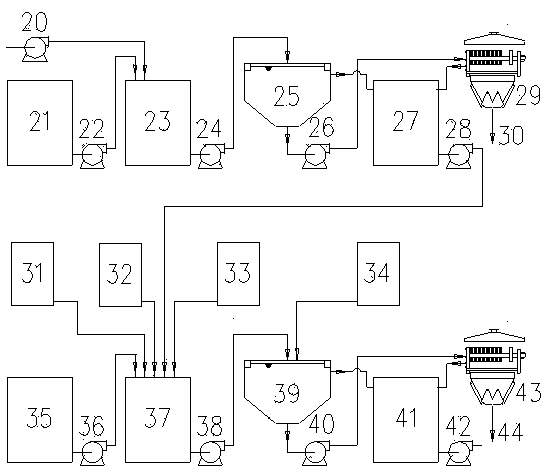

Processing system and method for cold rolling reverse osmosis strong brine

ActiveCN105016569ASolve the problem of meeting emission standardsReduce pollutionMultistage water/sewage treatmentReverse osmosisTotal nitrogen

The invention provides a processing system and method for cold rolling reverse osmosis strong brine. The processing system sequentially comprises a platy heat exchanger, a first-stage lifting pump, a nanometer zero-valent iron residue reactor, a second-stage lifting pump, a PH aeration reduction pool, a third-stage lifting pump, an integrated denitrification COD biochemical pool and a coagulative precipitation tank. The cold rolling reverse osmosis strong brine enters the zero-valent iron residue reactor after passing through the platy heat exchanger to be cooled so that heavy metal can be removed. The cold rolling reverse osmosis strong brine then enters the integrated denitrification COD biochemical pool after passing through the PH aeration reduction pool so that total nitrogen and organic matter can be removed. The cold rolling reverse osmosis strong brine finally enters the coagulative precipitation tank and can reach the standard and then be discharged after coagulating sedimentation. The processing system is low in one-time investment, easy to run and operate, low in production and processing cost and capable of processing environment-friendly steel waste water in a green and environment-friendly mode.

Owner:BAOSHAN IRON & STEEL CO LTD

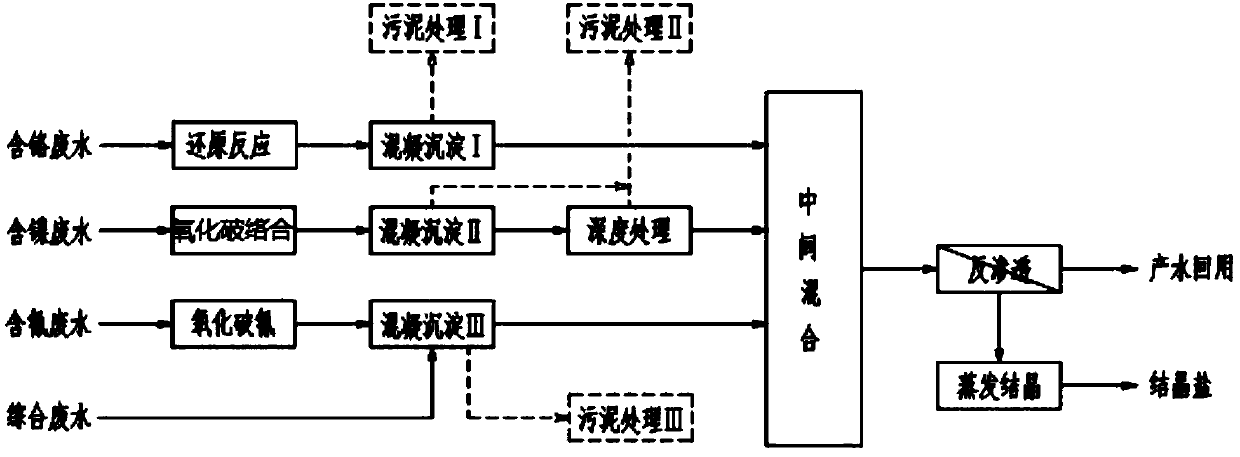

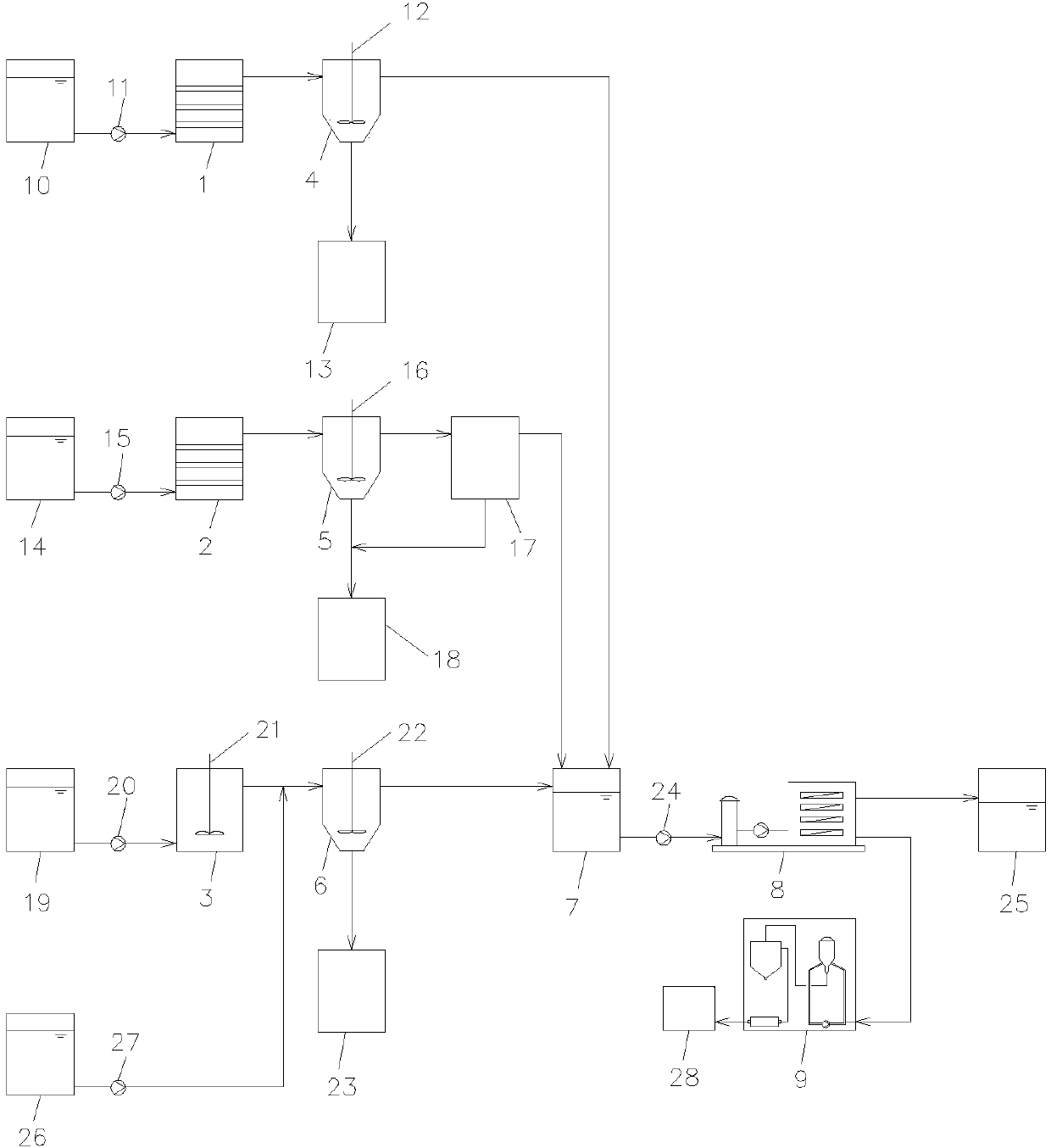

Electroplating wastewater processing technology and special-purpose apparatus thereof

PendingCN107840509ASolve the problem of meeting emission standardsSave waterWater contaminantsWaste water treatment from metallurgical processReverse osmosisEnvironmental engineering

The invention discloses an electroplating wastewater processing technology and a special-purpose apparatus thereof. The electroplating wastewater is divided into chromium-containing waste water, nickel-containing waste water, cyanogen-containing waste water and comprehensive waste water, and then is subjected to classified processing, the technology is characterized in that the chromium-containingwaste water is respectively subjected to reduction and coagulating sedimentation, and then is introduced into a middle mixing system; the nickel-containing waste water is subjected to oxidation complex breaking, coagulating sedimentation, and deep processing, and then is introduced into the middle mixing system; the cyanogen-containing waste water is subjected to oxidation cyanogen breaking, is introduced into a coagulating sedimentation system after being mixed with the comprehensive waste water, and after coagulating sedimentation, is introduced into the middle mixing system for mixing to obtain the mixed waste water. The mixed waste water is subjected to reverse osmosis membrane separating, and the obtained produced water can be reused. A concentrate is subjected to evaporative crystallization, and crystalline salt can be finally obtained. The electroplating wastewater processing technology can be recyclablely used for a production line, and the obtained crystalline salt can be recycled.

Owner:SHANGHAI JINGYU ENVIRONMENT ENG

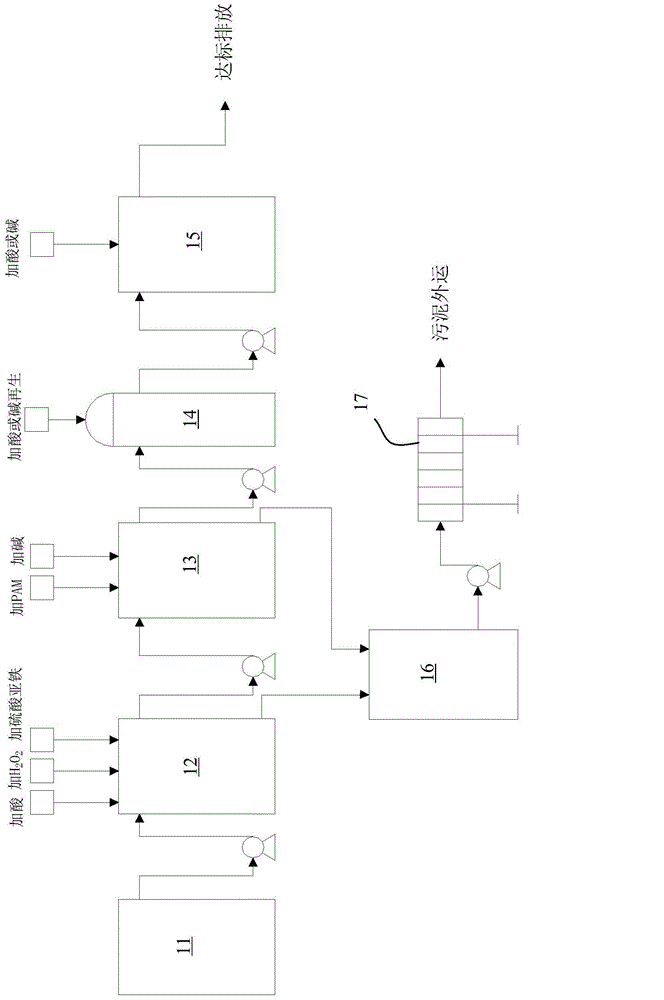

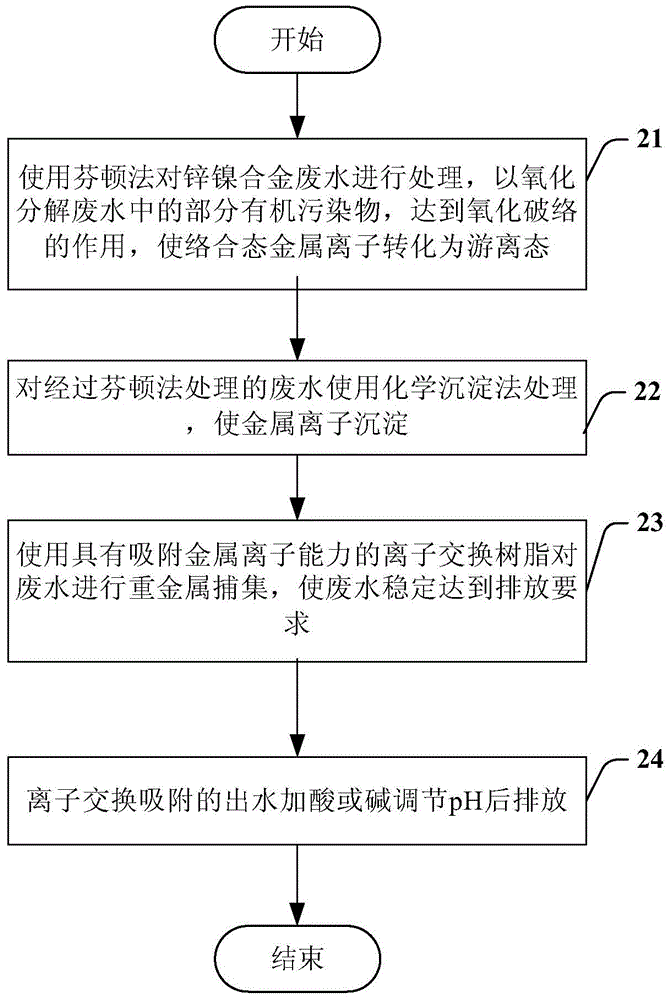

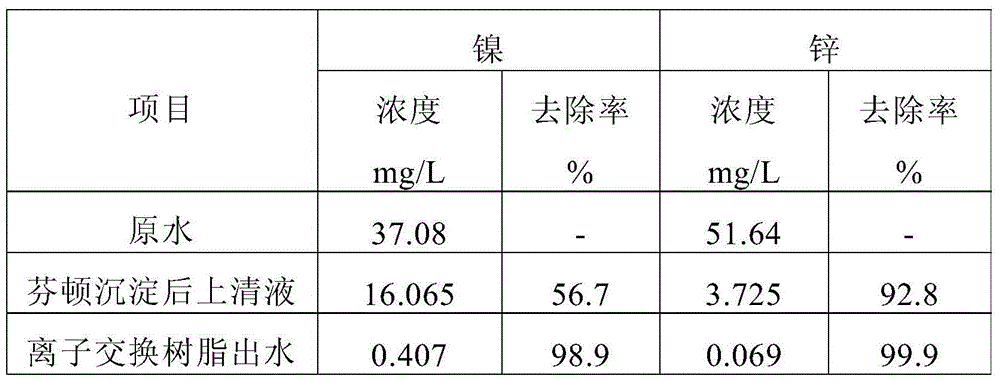

Up-to-standard treatment method and device for zinc-nickel alloy waste water

InactiveCN105800821ASolve the problem of meeting emission standardsEasy to operateWaste water treatment from metallurgical processMultistage water/sewage treatmentIonStandard treatment

The invention relates to an up-to-standard treatment method and device for zinc-nickel alloy waste water; the method includes the following steps: the zinc-nickel alloy waste water is treated by a Fenton method, so as to carry out oxygenolysis of a part of organic pollutants in the waste water, to achieve the oxidative complex breaking effect and make complexation metal ions turned into a free state; the waste water treated through the Fenton method is treated by a chemical precipitation method, to make metal ions precipitated; and the waste water is subjected to heavy metal capture by ion exchange resin having the ability to adsorb the metal ions, so that the waste water stably reaches emission requirements.

Owner:SHANGHAI LIGHT IND RES INST

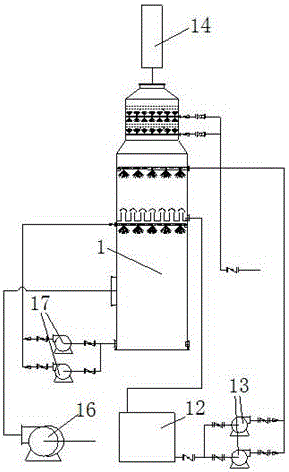

Treatment device and method for smelting flue gas collected from fugitive emission

ActiveCN106345259ASolve the problem of meeting emission standardsAchieve recyclingCombination devicesGas treatmentLiquid slagDust control

The invention particularly relates to a treatment device and method for smelting flue gas collected from fugitive emission. The treatment device comprises a desulfurizing tower; the desulfurizing tower comprises a tower body, and a demister and an alkaline liquid spraying device which are sequentially arranged in the tower body from top to bottom; a flue gas inlet, an acid water outlet and a drain outlet are formed in the side wall of the tower body; a flue gas outlet is formed in the top of the tower body; an alkaline liquid receiving device and an acid water spraying device are also sequentially arranged below the alkaline liquid spraying device; the alkaline liquid spraying device comprises a plurality of U-shaped grooves; and a gas-liquid separation cover supported by a supporting plate is arranged between two adjacent U-shaped grooves. On one hand, the treatment device realizes the dedusting and desulfurization treatment to flue gas to recover heavy metals in the flue gas and prevent the heavy metals from entering alkaline liquid and being absorbed to change the absorbed liquid slag to dangerous waste slag to increase the treatment difficulty and cost of the absorbed liquid; on the other hand, the recycling of the alkaline liquid can be realized, two functions with one tower can be realized, the equipment investment, alkali consumption and running cost can be effectively lowered, and the up-to-standard emission problem of the flue gas collected from fugitive emission can be solved.

Owner:JINCHUAN GROUP LIMITED

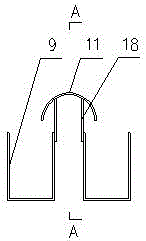

Method and device for treating rare-earth molten high ammonia nitrogen wastewater by using integrated membrane technology

PendingCN108128939ASolve the problem of meeting emission standardsImprove separation efficiencyWater contaminantsTreatment involving filtrationFiltrationUltrafiltration

The invention provides a method and device for treating rare-earth molten high ammonia nitrogen wastewater by using an integrated membrane technology. The method adopts a process of filter press / coarse filtration, complexing-ultrafiltration and reverse osmosis, and is used for treating rare-earth molten high ammonia nitrogen wastewater through pre-purification, complexing-ultrafiltration couplingand reverse osmosis. The device comprises a coarse filter device, an ultrafiltration feed pump, an ultrafiltration pressure valve, an ultrafiltration pressure gauge, a complexing agent water tank, anultrafiltration concentrate tank, an ultrafiltration membrane component, a reverse osmosis feed pump, a pH regulating tank, a reverse osmosis pressure valve, a reverse osmosis pressure gauge, a reverse osmosis membrane component, a reverse osmosis water production tank and a reverse osmosis concentrate tank. The method and device can be used for effectively solving the problems of ion type rare-earth industrial wastewater treatment and up-to-standard discharge and recycling ammonia and nitrogen in the wastewater, have the advantages of high separating and recycling efficiency, simple process,convenience in operation and the like, and have great development potential and wide application prospect in rare-earth industry.

Owner:ENERGY RES INST OF JIANGXI ACAD OF SCI

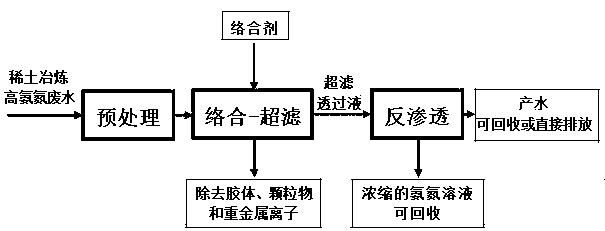

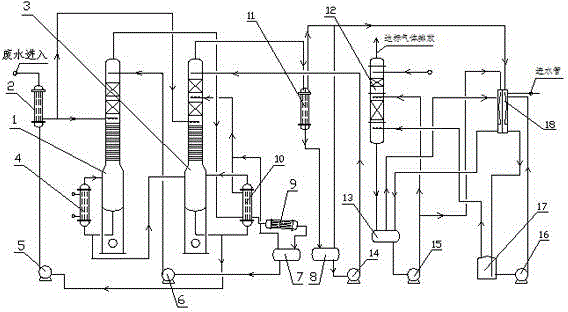

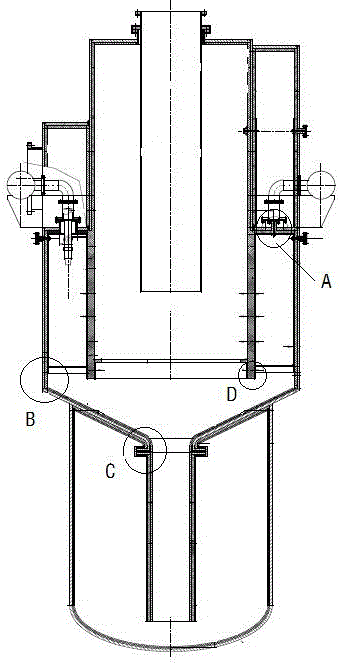

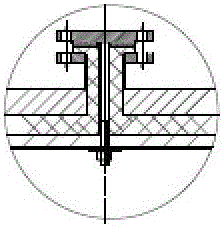

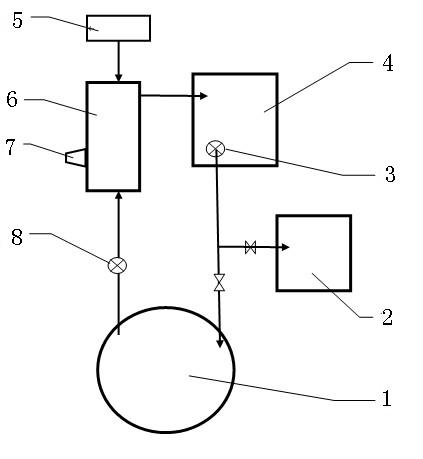

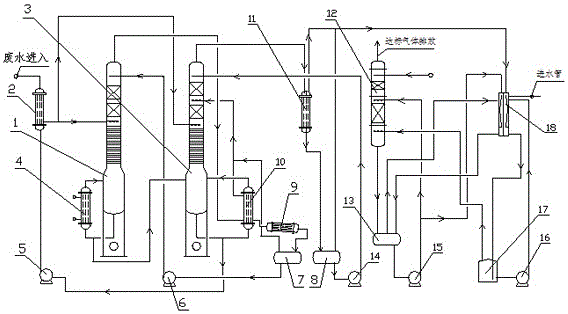

Double-tower catalysis thermal-coupling reflux deamination method and deamination device thereof

ActiveCN104860465AReduce partial pressureAchieve recyclingMultistage water/sewage treatmentReboilerEngineering

The invention discloses a double-tower catalysis thermal-coupling reflux deamination method. The method comprises steps as follows: a pH conditioner and a composite deamination agent are added to an ammonia-nitrogen wastewater buffer pool, the mixture is preheated, one part of preheated ammonia-nitrogen wastewater is sent into a middle section of a thermal pressurizing tower to be fully contacted with hot steam which is produced by a reboiler and rises in the thermal pressurizing tower, ammonia-containing steam produced at the top of the thermal pressurizing tower is sent into a reboiler of a low-pressure coupling tower for condensation and rectification, then the ammonia-containing steam is sent into the lower part of the low-pressure coupling tower for rectification, and deaminated wastewater produced at the bottom of the thermal pressurizing tower is sent into the bottom in the low-pressure coupling tower; meanwhile, the other part of the preheated ammonia-nitrogen wastewater is sent into a middle section of the low-pressure coupling tower to be fully contacted with the ammonia-containing steam, and ammonia-containing steam is produced at the top of the low-pressure coupling tower. The NH3-N index of the deaminated wastewater can reach the national first-class discharge standard (15 ppm), industrial ammonia water with high quality can be recovered, energy consumption is greatly reduced, and compared with conventional distillation technologies, the method has the advantages that the energy-saving efficiency is higher than 40% and economic benefit and social benefit are very significant.

Owner:JIANGXI NAIKE CHEM IND EQUIP PACKINGCO

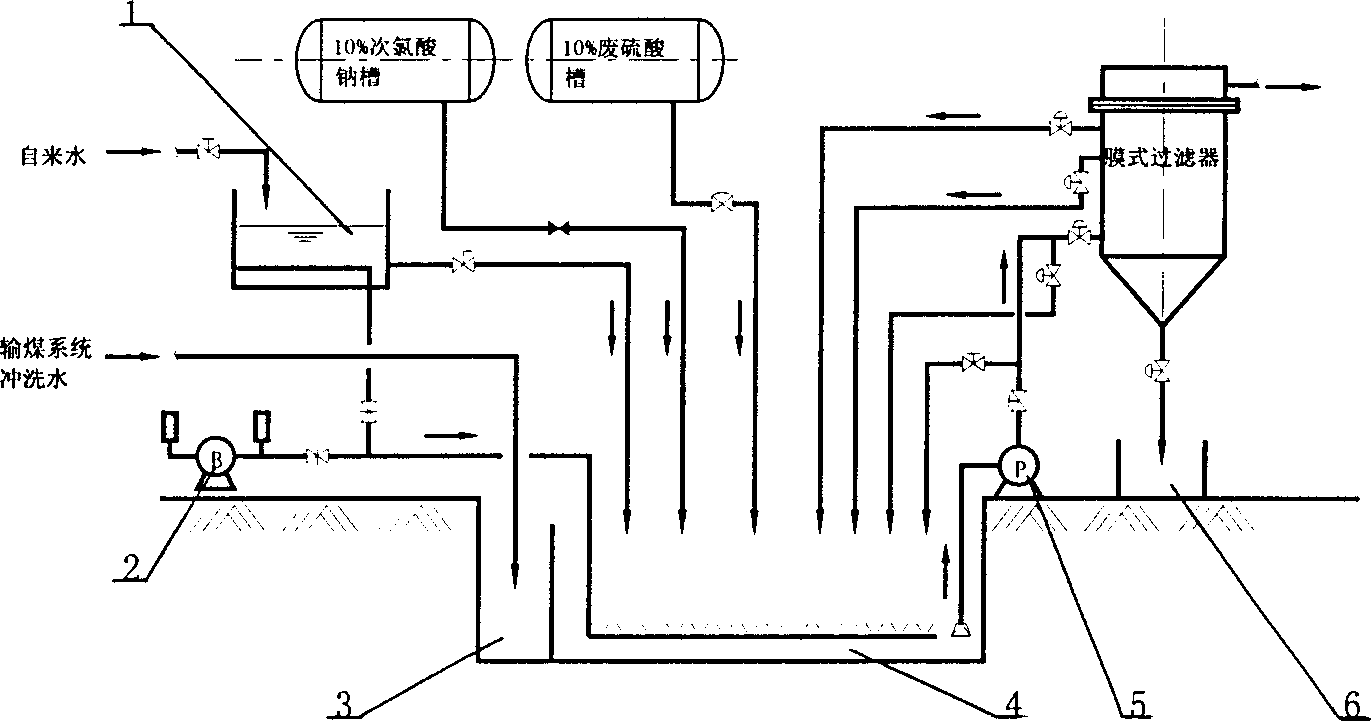

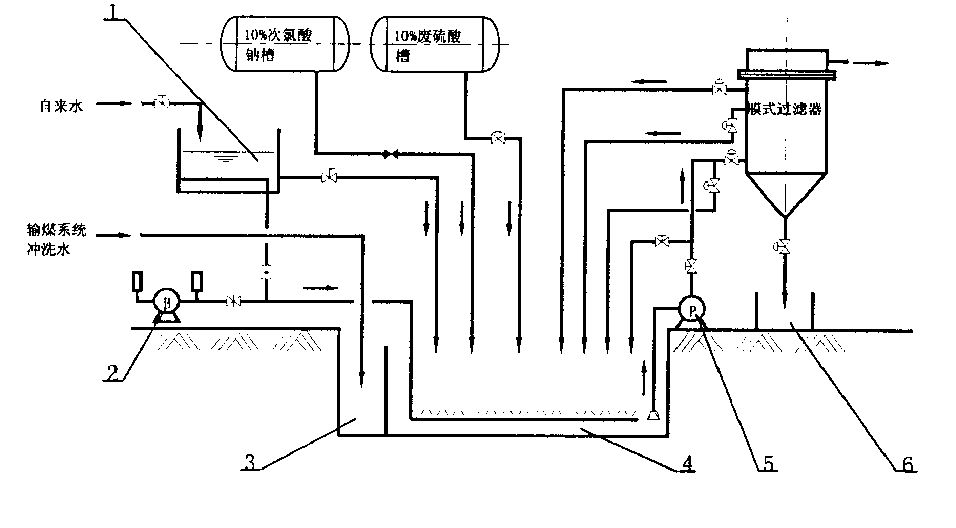

Process for treating waste water with coal ash

InactiveCN1334251ASolve the problem of meeting emission standardsReduce dosageMultistage water/sewage treatmentPower stationPulverized fuel ash

A process for treating waste water containing coal ash generated by flushing coal includes collecting said waste water in deposition pool, depositing, introducing the supernatant into neutralizing and aerating pool, adding 5-15% waste sulfuric acid for acidifying it, adding alkaline calcium carbide dreg liquid for neutralizing and aerating it, adding 10% sodium hypochlorite for disinfecting it, filtering and discharge. Its advantages are high effect and saving water.

Owner:LEFUMEN WATER TREATMENT ENG SHANGHAI

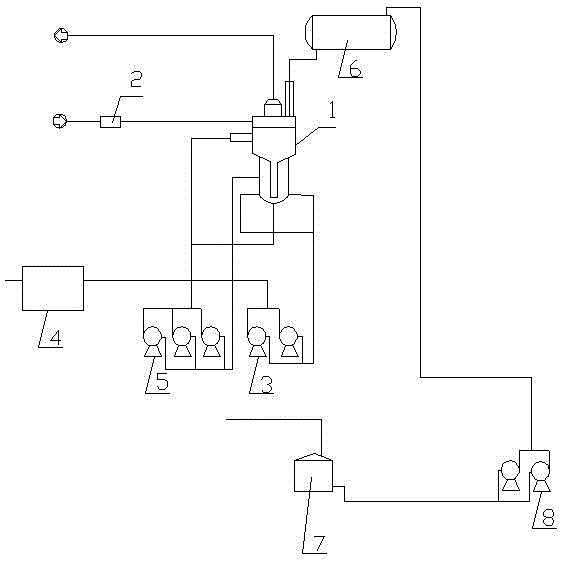

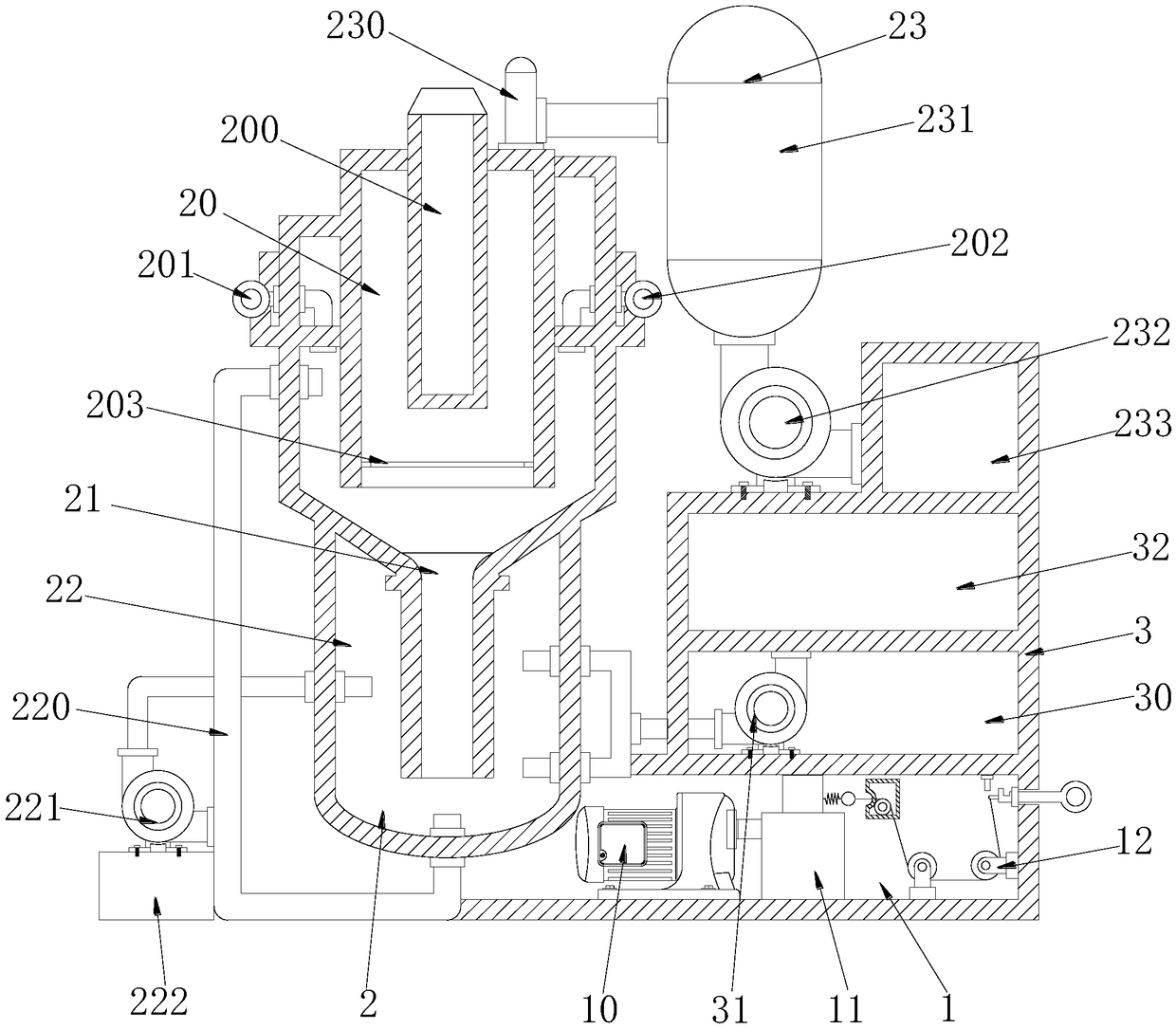

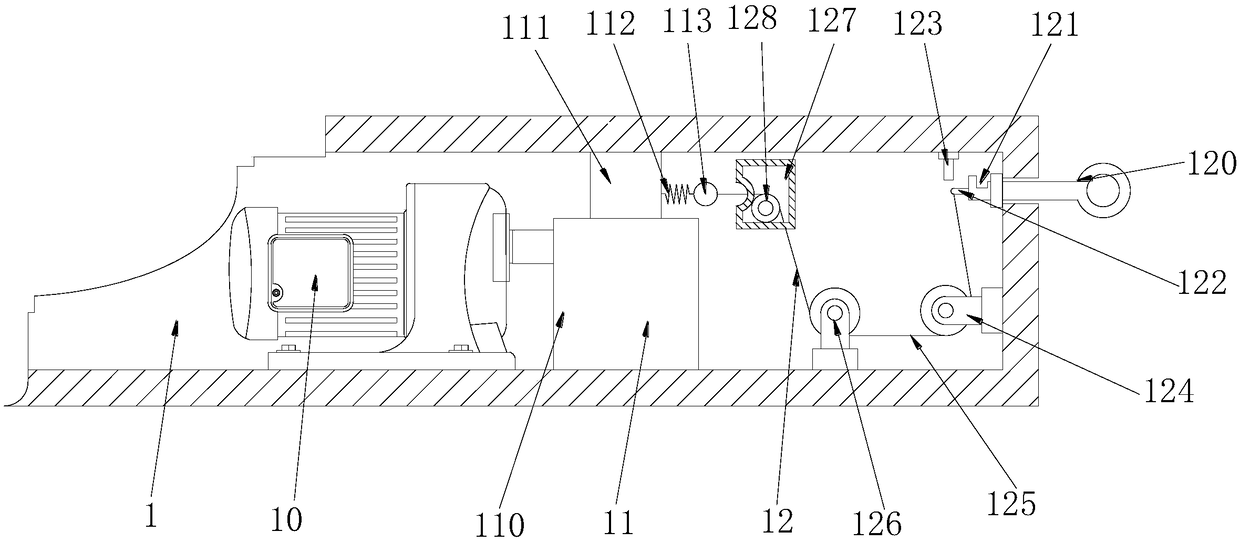

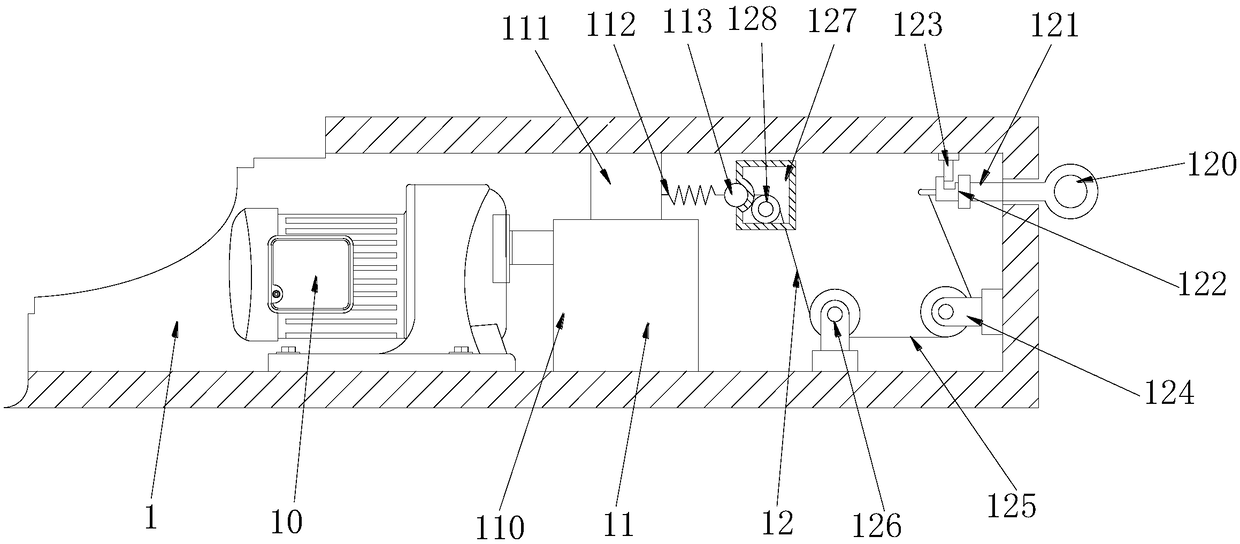

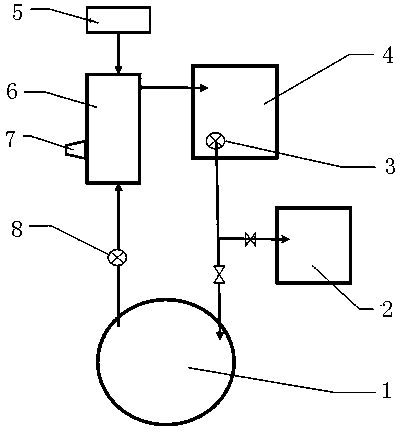

Saturated-reactor-process ammonia waste gas treatment device and process thereof

InactiveCN105833705AEasy to replaceSolve the problem of meeting emission standardsDispersed particle separationAmmonia compoundsWastewaterVinyl fibers

The invention relates to a saturated-reactor-process ammonia waste gas treatment device and a treatment process. The saturated-reactor-process ammonia waste gas treatment device comprises an ammonium sulfate saturator (1), a cooling device (2), a crystallization pump (3) and a crystallization tank (4), wherein the cooling device (2) is arranged on an ammonia waste gas inlet pipeline of the ammonium sulfate saturator (1); the ammonium sulfate saturator (1) takes carbon steel as a substrate material and vinyl fiber glass as an anti-corrosion lining; at a flashing part, the surface of the vinyl fiber glass is treated by using emery; no mother liquor allocation chamber is formed in the ammonium sulfate saturator (1); a pipeline allocator is arranged outside the ammonium sulfate saturator (1); a PO lining is arranged inside the pipeline allocator. When being adopted to treat an ammonia-contaminated waste gas and wastewater discharged in medicine production, the treatment process has the characteristics of reasonable process, advance technique, small investment and rapid effect taking, and the up-to-standard release of waste gases and wastewater is thoroughly realized.

Owner:TAIZHOU BAILLY CHEM CO LTD

Middling starch slurry and cassava fermentation alcohol wastewater treatment and thermoelectric fertilizer co-generation method

InactiveCN106830548ASolve the problem of meeting emission standardsRealize recyclingBio-organic fraction processingTreatment using aerobic processesCogenerationSlurry

The invention relates to the technical field of alcohol wastewater treatment, and provides a middling starch slurry and cassava fermentation alcohol wastewater treatment and thermoelectric fertilizer co-generation method. The method comprises the steps of 1 pretreatment of middling starch slurry and cassava fermentation alcohol wastewater, 2 anaerobic treatment for methane production, 3 methane conveying and thermoelectric co-generation, 4 wastewater up-to-standard discharge, 5 organic fertilizer processing. The method achieves the purposes that cassava and waste slurry generated when vital gluten and starch are generated by means of wheat flour are cooperatively adopted as raw materials, saccharomycetes is adopted for fermenting alcohol, and up-to-standard discharge of the generated wastewater is achieved; meanwhile, the thermoelectric fertilizer co-generation technology is developed, and recycling comprehensive utilization is achieved.

Owner:SUZHOU WANSHEN FLOUR PROD

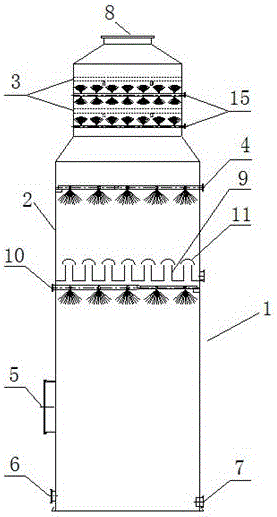

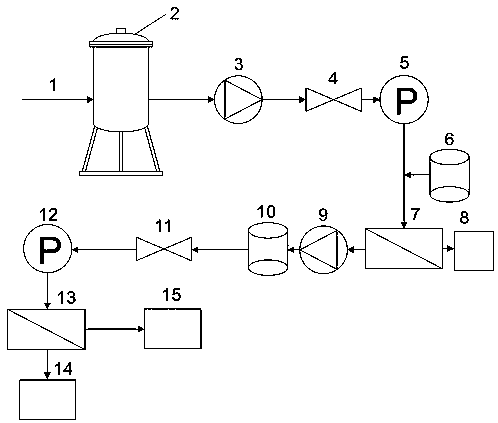

Dedusting system for flue gas ammonia desulphurization and application method of dedusting system

ActiveCN102600713ASolve severe wear and tearSolve problems such as blockageDispersed particle separationPipingSulfur dioxide

The invention relates to a dedusting system for boiler flue gas desulfurization, in particular to a dedusting system for flue gas ammonia desulfurization. The invention also relates to a method for applying the dedusting system in an ammonia desulfurization system. The dedusting system comprises a desulfurizing tower, a slurry pump, a centrifugal machine, a clear liquid pool, a clear liquid pump, an electric control system and an evaporation concentration system, wherein the desulfurizing tower, the slurry pump, the centrifugal machine and the clear liquid pump positioned in the clear liquid pool are sequentially connected in series through a pipeline to form a closed loop, the centrifugal machine is connected with the electric control system, the centrifugal machine is also provided with a mud outlet, and the pipeline between the clear liquid pump and the desulfurizing tower is connected with the evaporation concentration system. By the dedusting system and an application method of the dedusting system, provided by the invention, the problems that in the existing ammonia wet-type desulfurization system, due to desulfurizing circulating solution contains the large ash content, a pump valve, a nozzle, a piping system and the like are seriously worn and blocked, and the like can be effectively solved, so that the ammonia wet-type desulfurization system can safely and stably operate, and the sulfur dioxide emission can reach the standard for a long time.

Owner:兖矿科技有限公司

Saturator-method ammonia exhaust gas treatment device

InactiveCN109248553AReasonable structureAdvanced technologyDispersed particle separationAmmonium sulfateExhaust gas

The present invention discloses a saturator-method ammonia exhaust gas treatment device, structure of which comprises a total control power supply chassis, an ammonium sulfate saturator control device, a mother liquor crystallization control device, the ammonium sulfate saturator control device is provided with a top ammonium sulfate saturator device, a reaction control pipe, a bottom reaction control box, a sulfuric acid high-level storage device, and the mother liquor crystallization control device is provided with a crystallization pump work box, a control crystallization pump, and a crystallization cleaning work box. The treatment device has the beneficial effects that the utility model can be operated by a simple operation driving device, and is characterised in reasonable structure,advanced technology, low investment and quick effect, and can completely solve a problem of exhaust gas and waste water emissions.

Owner:丁文铃

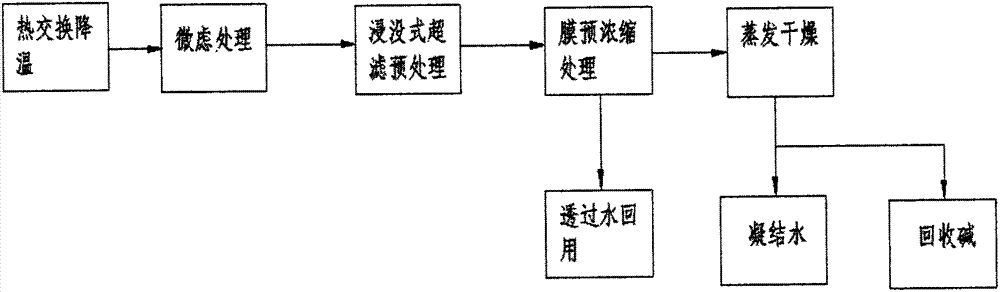

Method for concentrating CMP (chemi-mechanical pulp) waste liquid by using membrane process

ActiveCN102249436BSolve the problem of meeting emission standardsGuarantee continuous and stable operationPulp liquor regenerationGeneral water supply conservationLiquid wasteIndustrial waste water

The invention relates to the field of industrial waste water treatment, particularly relates to and discloses a method for concentrating CMP (chemi-mechanical pulp) waste liquid by using a membrane process. The method comprises the following steps: (1) heat exchange for cooling; (2) microfiltration treatment; (3) ultrafiltration pretreatment; and (4) membrane preconcentration. In the CMP waste liquid treatment method provided by the invention, the CMP waste liquid with initial concentration by mass percentage of 1-2% is concentrated to 7-10% by a membrane concentration system, and penetrationliquid can be directly discharged or reused. Through adopting an immersed ultrafiltration and reverse-osmosis / nanofiltration preconcentration process and a series of membrane pollution control techniques, the smoothly continuous operation of the system can be ensured, thereby realizing the zero discharge of the CMP waste liquid. By using the method provided by the invention, the problem that the CMP waste liquid is treated to meet the States discharge standards can be completely solved; and compared with a direct evaporation and concentration mode, the method is characterized by adopting preconcentration of the membrane system, the energy consumption is greatly reduced, and a good deal of produced water can be recycled, therefore, the method provided by the invention has good economic andsocial benefits.

Owner:ZHEJIANG CREATION ENVIRONMENT TECH

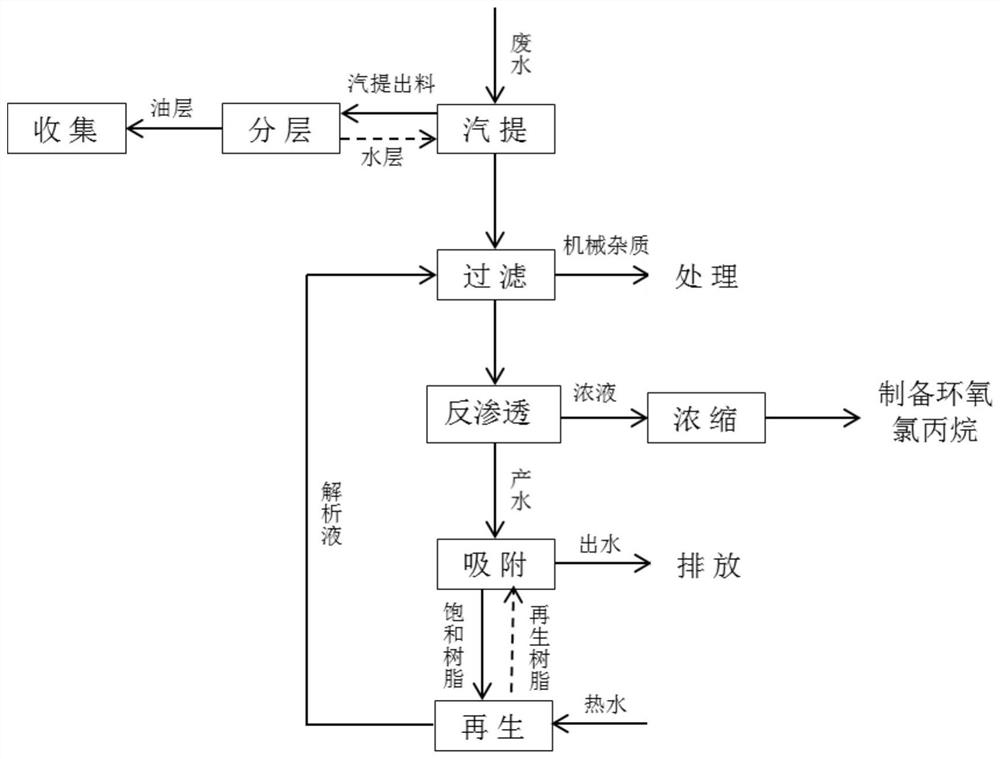

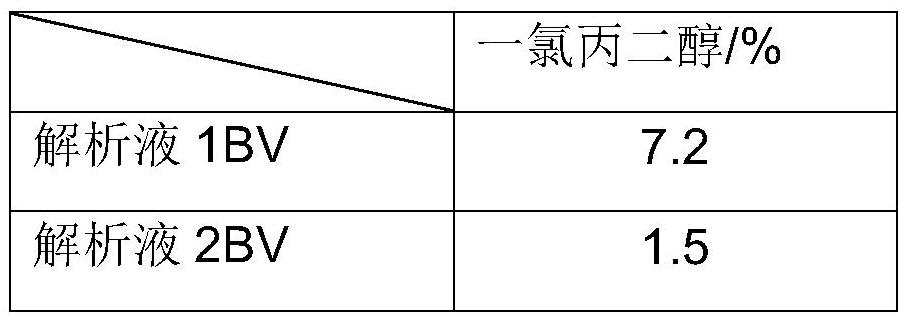

A method for resource utilization of epichlorohydrin waste water

ActiveCN110482756BEfficient separationSolve resource problemsWater treatment parameter controlWater contaminantsFiltrationReverse osmosis

The invention provides a resource treatment scheme for epichlorohydrin wastewater, which can effectively separate water and organic matter through the processes of stripping, oil-water stratification, filtration, reverse osmosis membrane device concentration, resin adsorption, and resin regeneration, and realize the recycling of wastewater. Oxychloropropane and monochloropropanediol are recovered, and the effluent is discharged up to the standard, with broad application prospects.

Owner:JIANGSU YANGNONG CHEM GROUP +2

Dedusting system for flue gas ammonia desulphurization and application method of dedusting system

ActiveCN102600713BGuaranteed uptimeAchieving long-term emissions complianceDispersed particle separationFlue gasDust control

The invention relates to a dedusting system for boiler flue gas desulfurization, in particular to a dedusting system for flue gas ammonia desulfurization. The invention also relates to a method for applying the dedusting system in an ammonia desulfurization system. The dedusting system comprises a desulfurizing tower, a slurry pump, a centrifugal machine, a clear liquid pool, a clear liquid pump, an electric control system and an evaporation concentration system, wherein the desulfurizing tower, the slurry pump, the centrifugal machine and the clear liquid pump positioned in the clear liquid pool are sequentially connected in series through a pipeline to form a closed loop, the centrifugal machine is connected with the electric control system, the centrifugal machine is also provided with a mud outlet, and the pipeline between the clear liquid pump and the desulfurizing tower is connected with the evaporation concentration system. By the dedusting system and an application method of the dedusting system, provided by the invention, the problems that in the existing ammonia wet-type desulfurization system, due to desulfurizing circulating solution contains the large ash content, a pump valve, a nozzle, a piping system and the like are seriously worn and blocked, and the like can be effectively solved, so that the ammonia wet-type desulfurization system can safely and stably operate, and the sulfur dioxide emission can reach the standard for a long time.

Owner:兖矿科技有限公司

Method of treating emulsion liquid waste water using industrial spent acid

InactiveCN1140468CLow costSolve the problem of meeting emission standardsWater/sewage treatment by neutralisationWater/sewage treatment by sorptionLiquid wasteWater use

Owner:BAOTA IND CO LTD

A combined biological bed treatment process for waste water with low carbon source, high ammonia nitrogen and high organic phosphorus

ActiveCN109354314BSolve the problem of meeting emission standardsImprove biochemical treatment efficiencyWater contaminantsMultistage water/sewage treatmentAmmoniacal nitrogenOrganic phosphorus

The present invention provides a combined biological bed treatment process for waste water with low carbon source, high ammonia nitrogen and high organic phosphorus, including five steps of raw water adjustment, iron-carbon-Nefton treatment, struvite treatment, A2O treatment, and Fenton advanced treatment. The first flocculant and the second flocculant are respectively added in the iron-carbon-Nefton treatment step and the Fenton advanced treatment step; the present invention adopts the low-carbon source high ammonia nitrogen high organic phosphorus wastewater combined biological bed treatment process as the low-carbon source high The main treatment method of ammonia nitrogen and high phosphorus wastewater greatly improves the efficiency of biochemical treatment, solves the problem of low-carbon source high ammonia nitrogen and high organic phosphorus wastewater discharge standards, and has good social and economic benefits; Nefenton, iron-carbon micro-electrolysis The combination with Fenton can improve the Fenton effect, reduce operating costs and operating workload.

Owner:XINJIANG LVFENG ENVIRONMENT PROTECTION ENG CO LTD

Method for treating livestock and poultry breeding waste water

InactiveCN102807302BAvoid inhibitionSufficient alkalinityBio-organic fraction processingClimate change adaptationChemical oxygen demandFiltration

The invention provides a method for treating livestock and poultry breeding waste water. The method mainly comprises the following steps of solid-liquid separation treatment, efficient nitrogen-phosphorus biochemical circulation treatment, modified oxidation ditch treatment, sludge reflux treatment, filtration and sterilization treatment and the like. The invention aims to provide the method for treating the livestock and poultry breeding waste water, which is high in capability of removing ammonia nitrogen, total nitrogen and total phosphorus and low in investment cost and running cost, and is easier to manage. The waste water treated by adopting the method provided by the invention can meet the requirement of the national Discharge standard of water pollutants for livestock and poultry breeding GB18596-2001; not only can the up-to-standard discharge requirement in the waste water treatment of the livestock and poultry breeding industry be effectively met, but also the difficult problem of removing the ammonia nitrogen while an organic matter is degraded is also solved; and the method is suitable for the waste water treatment of breeding farms on different breeding scales, similarly, is also suitable for the treatment of municipal domestic waste water and waste water with a high COD (chemical oxygen demand) or high ammonia nitrogen characteristic, and is wide in application prospect.

Owner:南宁绿智环保科技有限公司

A double-tower catalytic thermal coupling countercurrent deamination method and its deamination device

ActiveCN104860465BReduce partial pressureAchieve recyclingMultistage water/sewage treatmentSocial benefitsReboiler

The invention discloses a double-tower catalysis thermal-coupling reflux deamination method. The method comprises steps as follows: a pH conditioner and a composite deamination agent are added to an ammonia-nitrogen wastewater buffer pool, the mixture is preheated, one part of preheated ammonia-nitrogen wastewater is sent into a middle section of a thermal pressurizing tower to be fully contacted with hot steam which is produced by a reboiler and rises in the thermal pressurizing tower, ammonia-containing steam produced at the top of the thermal pressurizing tower is sent into a reboiler of a low-pressure coupling tower for condensation and rectification, then the ammonia-containing steam is sent into the lower part of the low-pressure coupling tower for rectification, and deaminated wastewater produced at the bottom of the thermal pressurizing tower is sent into the bottom in the low-pressure coupling tower; meanwhile, the other part of the preheated ammonia-nitrogen wastewater is sent into a middle section of the low-pressure coupling tower to be fully contacted with the ammonia-containing steam, and ammonia-containing steam is produced at the top of the low-pressure coupling tower. The NH3-N index of the deaminated wastewater can reach the national first-class discharge standard (15 ppm), industrial ammonia water with high quality can be recovered, energy consumption is greatly reduced, and compared with conventional distillation technologies, the method has the advantages that the energy-saving efficiency is higher than 40% and economic benefit and social benefit are very significant.

Owner:JIANGXI NAIKE CHEM IND EQUIP PACKINGCO

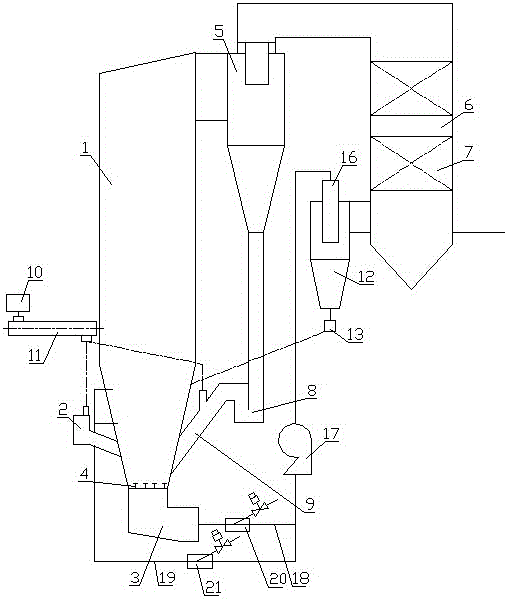

A circulating fluidized bed boiler oxygen-enriched combustion dry desulfurization system and method

ActiveCN104807002BSolve the problem of meeting emission standardsIncrease profitFluidized bed combustionSolid fuel pretreatmentCycloneHearth

The invention discloses a circulating fluidized bed boiler oxygen-enriched combustion dry desulphurization system and method. The dry desulphurization system comprises a hearth, a coal feeding hole, a primary air chamber, an air distribution device, a high-temperature cyclone separator, a tail flue, a coal economizer and a return device, wherein a desulfurizer feeding hole is formed in the coal feeding hole or / and in a return leg of the return device; a medium-temperature cyclone separator is arranged on the tail flue on the rear of the coal economizer; a return bin of the medium-temperature cyclone separator is connected with the hearth through a pipeline; a central drum of the medium-temperature cyclone separator is connected with the primary air chamber through an air hose and a primary air hose and is connected with the hearth through the air hose and a secondary air hose; an induced draft fan is arranged on the air hose; an oxygen injection device is arranged on at least one of the air hose, the primary air hose and the second air hose. The circulating fluidized bed boiler oxygen-enriched combustion dry desulphurization system can effectively solve the SOx up-to-standard discharge problem of a boiler, increase the utilization ratio of limestone, reduce consumption of limestone, improve desulphurization efficiency, realize efficient and economical desulphurization in the boiler as well as CO2 enrichment, facilitate compression, purification, utilization, sealing and storage of CO2, and meet environmental protection demand.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

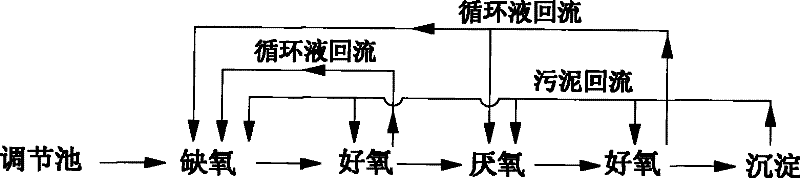

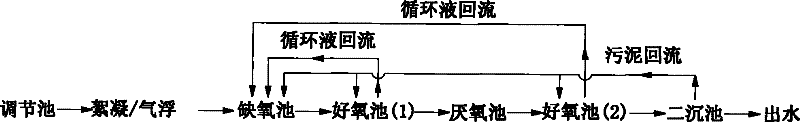

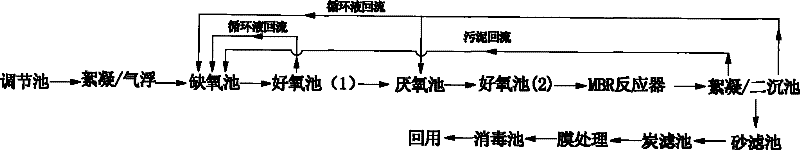

Multi-stage composite processing technology of high-concentration organic sewage

ActiveCN101386460BImprove biochemical treatment efficiencySolve the problem of meeting emission standardsTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationAfter treatment

The present invention relates to a multi-stage combination process used for the treatment of organic wastewater of high concentration, comprising a pretreatment process, a biochemical treatment process and a post-treatment process. The biochemical treatment process comprises the following steps: 1) the raw water passes a regulating tank and enters an anoxic tank for anoxic biodegradation; 2) the effluent after the anoxic biodegradation enters an aerobic tank for second biodegradation; 3) the effluent after the aerobic treatment enters an anaerobic tank for biodegradation or flows back to the anoxic tank for recirculation; 4) the effluent after the anaerobic treatment enters a second stage aerobic tank for further degradation or flows back to the anaerobic tank for recirculation; 5) the effluent after the second stage aerobic treatment flows back to the anoxic tank, wherein the effluent after the second stage aerobic treatment enters an aerobic tank and the backflow ratio of the anaerobic tank is 50% to 200%, and the final effluent enters a sedimentation tank, and the effluent meeting the standard after the sedimentation, together with the sludge, is discharged. The processes of the invention can also be provided with a plurality of stages of pretreatment steps and a plurality of post-treatment processes. The processes of the invention can ensure that any high concentration organic wastewater after treatment meets the discharge standard and the wastewater can be recycled.

Owner:深圳市先科环保有限公司

A kind of preparation method of polyvinylidene fluoride composite separation membrane

InactiveCN108993172BGuarantee direct compliance with emission standardsGuaranteed reuseSemi-permeable membranesPhosphateMaterials science

The invention discloses a preparation method of a polyvinylidene fluoride composite separation membrane. Firstly, an alkalized polyvinylidene fluoride membrane is prepared and subjected to grafting modification with acrylamide and oxidation with sodium hypochlorite, and the treated membrane conducts chemical bonding action with graphite oxide and tetraethylenepentamine respectively; then a graphite oxide-polyvinylidene fluoride-tetraethylenepentamine separation membrane is prepared through the phase transfer technology; and finally an aromatic amide nanofiltration ultra-thin layer is formed onthe surface of the graphite oxide-polyvinylidene fluoride-tetraethylenepentamine separation membrane through an interfacial polymerization reaction, and the polyvinylidene fluoride composite separation membrane is prepared. The composite separation membrane prepared by the invention can effectively reject and remove high concentration of pollutants such as heavy metals, nitrates and phosphates inwastewater, the problem of up-to-standard discharge of water-soluble pollutants in the water body is solved, and the polyvinylidene fluoride composite separation membrane has a wide application prospect in the field of water treatment.

Owner:宋泽霖

Catalytic wet oxidation pretreatment method of glyphosate production wastewater

ActiveCN103663667BHigh activityReduce dosageMultistage water/sewage treatmentWater/sewage treatment by oxidationPretreatment methodChemical oxygen demand

The invention relates to a catalytic wet oxidation pretreatment method of glyphosate production wastewater, comprises the following steps: firstly regulating pH value to be more than 8 and less than 10, adding a multi-component homogeneous catalyst and carrying out oxidative degradation on pollutants in wastewater for 0.3-2 hours by using a continuous catalytic wet oxidation device with air as an oxidizing agent at the reaction temperature of 210-230 DEG.C and the reaction pressure of 2-4MPa, wherein the catalyst is a soluble transition metal salt mixture. By adopting the method for treating the glyphosate production wastewater, the organic phosphorus conversion rate is high, the COD (chemical oxygen demand) removal rate is high, the biodegradability of the wastewater can be improved, and the secondary pollution is avoided. The method has the advantages that the catalyst activity is high, low in cost and easy to get, reaction conditions are relatively mild, and continuous operation is easily implemented; the glyphosate production wastewater can be discharged in standard through the combined process of catalytic wet oxidation pretreatment-routine technical dephosphorization and deamination-biochemistry, and the industrialized application prospect is great.

Owner:中国中化股份有限公司 +2

System and method for treating waste gas and wastewater

ActiveCN105396423BAchieve reuseSolve the problem of meeting emission standardsCombination devicesWater/sewage treatment by electrochemical methodsLiquid wasteElectricity

The invention discloses a waste gas and waste water treating system comprising a circularly collected flue gas treatment system containing a magnesium oxide absorption liquid, an acid water neutralizing treatment system and an electrochemical treatment system, wherein an inlet of the circularly collected flue gas treatment system is connected with a fan for delivering smelting circularly collected flue gas, a waste liquor outlet of the circularly collected flue gas treatment system is communicated with an inlet of the acid water neutralizing treatment system through a pipeline provided with an absorption liquid delivery pump, a neutralization liquid discharge port of the acid water neutralizing treatment system is connected with an input end of a neutralization liquid delivery pump, an output end of the neutralization liquid delivery pump is connected with two pipelines, one pipeline is introduced into the circularly collected flue gas treatment system, and the other is introduced into the electrochemical treatment system. Acid waste water is neutralized by use of effective components in the absorption liquid and the magnesium oxide solution, one part of waste water enters the prepared magnesium oxide solution for smelting circularly collected flue gas, the water discharge of the system is reduced, the other part enters the electrochemical treatment system for deep treatment and is discharged after reaching the standard, and up-to-standard emission or recycling of the smelting circularly collected flue gas and the acid waste water is realized.

Owner:JINCHUAN GROUP LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com