Catalytic wet oxidation pretreatment method of glyphosate production wastewater

A technology for catalyzing wet oxidation and producing wastewater, which is applied in the fields of oxidized water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. High-level problems, to achieve the effect of saving investment and operating costs, solving the problem of meeting the emission standards, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

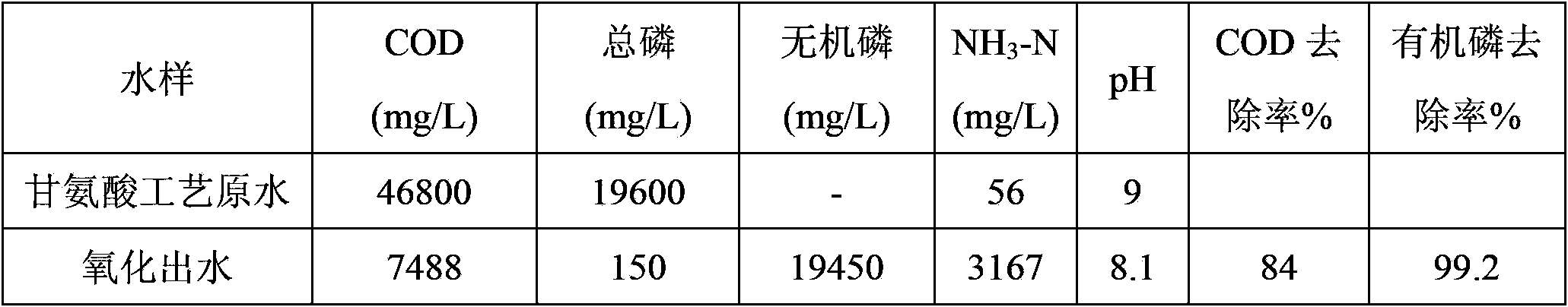

[0028] Take 2000mL of glyphosate production wastewater from the glycine process, adjust the pH to 9.0 with 1mol / L HC solution, add 0.2g of copper sulfate and 0.4g of zinc nitrate mixed catalyst, stir evenly, and send it into the preheater through a high-pressure metering pump, and the wastewater flow rate is 240ml / h; Adjust the air pressure of the high-pressure steel cylinder to 3MPa through the pressure reducing valve, and the quality controller controls the air flow rate of 690ml / min to mix with the waste water in the preheater, and then send it to the reactor for oxidation reaction after being heated to 230°C by an automatic temperature control electric heating device , the residence time of wastewater in the reactor is 20min, and the treated gas and water mixtures are condensed by the condenser and separated by the gas-liquid separator, and then discharged separately. The water quality analysis results before and after catalytic wet oxidation of wastewater are shown in Tabl...

Embodiment 2

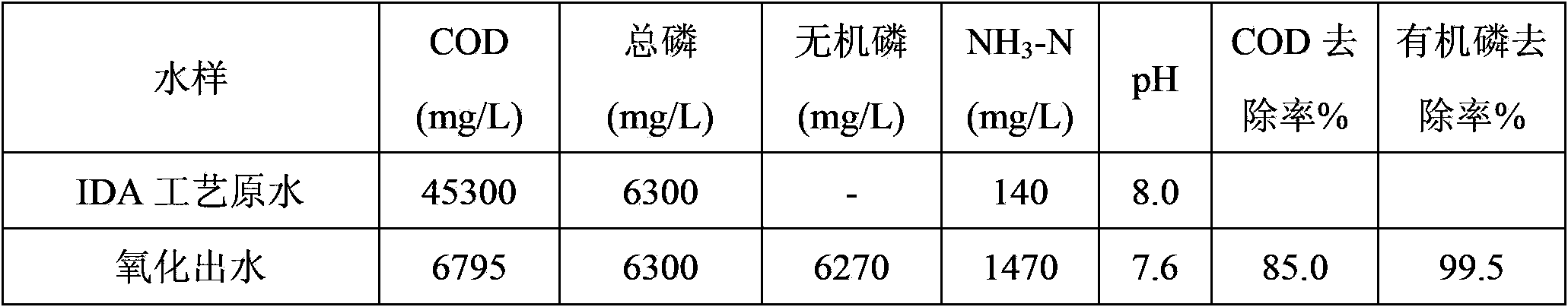

[0032] Take 2000mL of IDA process glyphosate production wastewater, adjust the pH to 8.5 with 1mol / L NaOH solution, add 0.2g of copper sulfate and 0.4g of zinc nitrate, stir evenly, and send it into the preheater through a high-pressure metering pump, and the wastewater flow rate is 240ml / h; The air pressure of the high-pressure steel cylinder is adjusted to 4MPa through the pressure reducing valve, and the quality controller controls the air flow rate of 690ml / min to mix with the waste water in the preheater. After being heated to 220°C by the automatic temperature control electric heating device, it is sent to the reactor for oxidation reaction, and the waste water The residence time in the reactor is 20 minutes. The treated gas and water mixtures are condensed by the condenser and separated by the gas-liquid separator, and then discharged separately. The water quality analysis results before and after catalytic wet oxidation of wastewater are shown in Table 2.

[0033] Table...

Embodiment 3

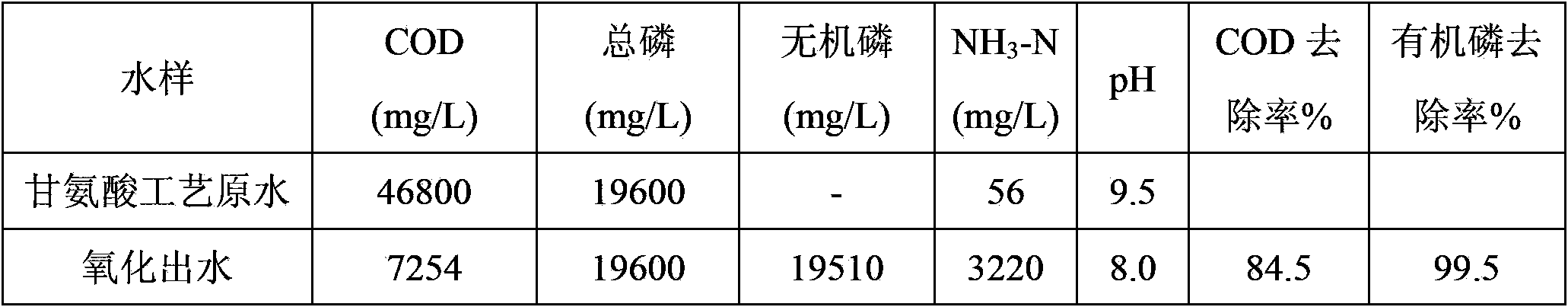

[0037] Take 2000mL of glyphosate production wastewater from the glycine process, adjust the pH to 9.5 with 1mol / L HCL solution, add 0.4g of copper sulfate and 0.4g of zinc nitrate mixed catalyst, stir evenly, and send it into the preheater through a high-pressure metering pump, and the wastewater flow rate is 240ml / h; Adjust the air pressure of the high-pressure steel cylinder to 4MPa through the pressure reducing valve, and the quality controller controls the air flow rate of 690ml / min to mix with the waste water in the preheater, and then send it to the reactor for oxidation reaction after being heated to 210°C by automatic temperature control. The residence time in the reactor is 20 minutes. The treated gas and water mixtures are condensed by the condenser and separated by the gas-liquid separator, and then discharged separately. The water quality analysis results before and after catalytic wet oxidation of wastewater are shown in Table 3.

[0038] Table 3 Pretreatment resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com