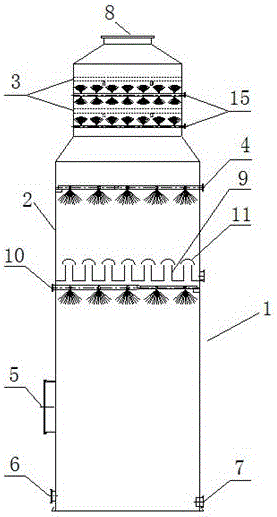

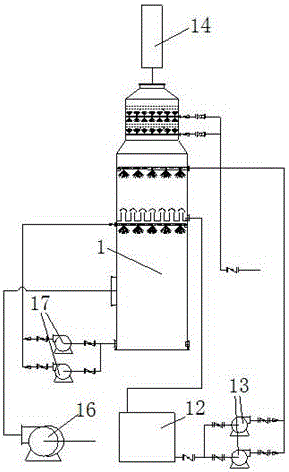

Treatment device and method for smelting flue gas collected from fugitive emission

A flue gas and liquid contact device technology, applied in the field of flue gas treatment, can solve the problems of poor treatment effect, poor pertinence, and intermittently excessive sulfur dioxide concentration, so as to reduce equipment investment, solve the problem of up-to-standard emission, and increase the difficulty of treatment. and cost effect

- Summary

- Abstract

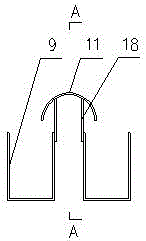

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Send the liquid caustic soda with a concentration of 31.5% to the liquid caustic soda circulation tank, add water to make a dilute caustic soda with a concentration of 10.3%, add the acid water to the desulfurization tower, after reaching a certain level, turn on the acid water circulation pump, and send the acid water to the desulfurization tower. To the acid water spraying device of the desulfurization tower, it is passed into the smelting flash furnace to collect the flue gas, and the acid water spraying device is started to wash and cool the flue dust in the flue gas for the first time; to detect the concentration of sulfur dioxide in the flue gas. When the standard is met, turn on the liquid alkali circulating pump and run it for 24 hours. The concentration of sulfur dioxide in the flue gas collected at the entrance of the desulfurization tower: 437mg / Nm 3 ~6185mg / Nm 3 , the average concentration is 2818mg / Nm 3 , dust concentration: 63-194mg / Nm 3 , with an averag...

Embodiment 2

[0020] Send the liquid caustic soda with a concentration of 31.5% to the liquid caustic soda circulation tank, add water to prepare a dilute caustic soda with a concentration of 10.3%, add the acid water to the desulfurization tower, after reaching a certain level, turn on the sour water circulation pump, and send the water to The acid water spraying device of the desulfurization tower is connected to the smelting reverberatory furnace to collect the flue gas, and the acid water spraying device is started to wash and cool the dust in the flue gas collected for the first time; the concentration of sulfur dioxide in the flue gas is not up to standard, Turn on the liquid alkali circulation pump and run for 24 hours, the concentration of sulfur dioxide in the flue gas: 553mg / Nm 3 ~16185mg / Nm 3 , with an average concentration of 3826mg / Nm 3 , dust concentration: 69-732mg / Nm 3 , average concentration: 422mg / Nm 3 , Flue gas volume: 93256Nm 3 / h~103851Nm 3 / h, the average gas vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com