System and method for treating waste gas and wastewater

A flue gas treatment system and technology of the treatment system, applied in the direction of neutralization water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high cost and large alkali consumption, Reach the effect of reducing operating costs, achieving emission standards, and strong pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

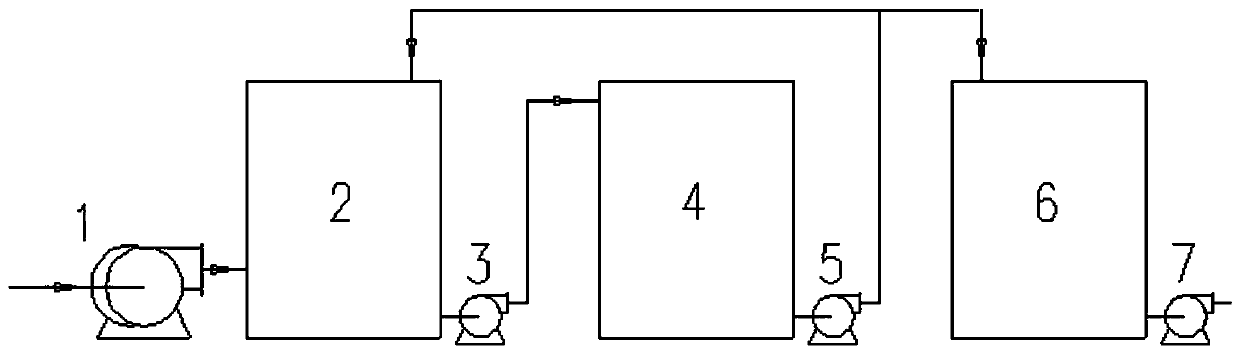

[0031] Such as figure 1 Shown, the technological process of the present invention is described further:

[0032] The smelting ring collection flue gas is sent to the ring collection flue gas treatment system 2 by the fan 1, and the flue gas is absorbed by the magnesium oxide solution. The acid water is neutralized so that the magnesium oxide can be fully utilized. After the acid water is neutralized, a part of the neutralization liquid is sent to the ring collection flue gas treatment system 2 through the neutralization liquid delivery pump 5, and is used for magnesium oxide slurry mixing, and the water volume does not increase any more. , the remaining part of the neutralizing solution enters the electrochemical treatment system 6 for further processing, and after reaching the standard, it is reused or discharged by the delivery pump 7.

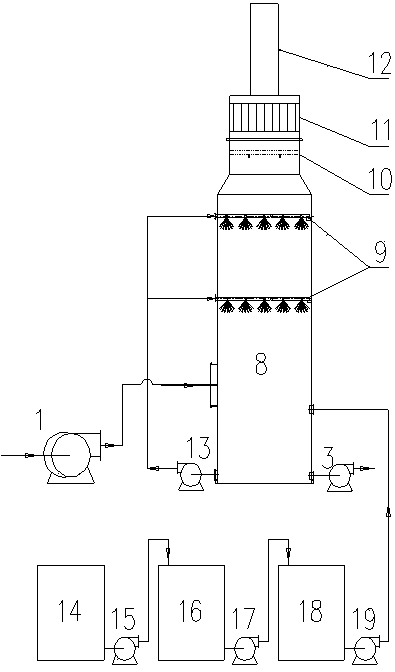

[0033] Such as figure 2 As shown in the figure, a further description of the ring-set flue gas treatment system is given:

[0034] Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com