Reverse osmosis membrane treating and recycling method for printing and dyeing wastewater

A technology for reverse osmosis membrane, printing and dyeing wastewater, applied in water/sewage treatment, water treatment parameter control, special compound water treatment, etc. It can improve the recycling rate, avoid the collapse of the biological treatment system, and solve the problem of meeting the emission standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

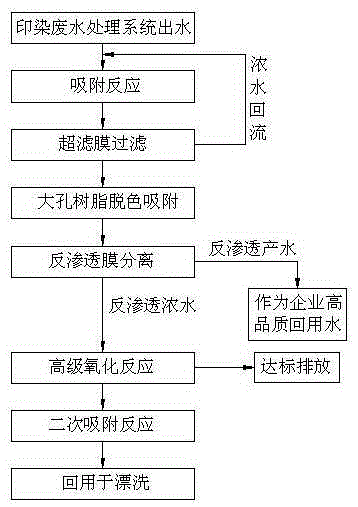

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] like figure 1 Shown is the flowchart of the present invention,

[0029] A reverse osmosis membrane treatment and reuse method for printing and dyeing wastewater, comprising the following steps:

[0030] Step 1. Adsorption reaction: Take the effluent from the printing and dyeing wastewater treatment system, enter the adsorption pool for adsorption reaction, remove the organic matter in the wastewater, and obtain the adsorbed effluent; the adsorption pool uses multiple reaction pools to operate in parallel. When the saturation fails, take it out for dehydration, and enter the regeneration equipment for regeneration and reactivation.

[0031] The adsorption material in the adsorption pool is granular activated carbon, and the natural loss of each regeneration of granular activated carbon is 5-10%.

[0032] The adsorption material can al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com