Saturated-reactor-process ammonia waste gas treatment device and process thereof

A waste gas treatment device and waste gas treatment technology, applied in chemical instruments and methods, ammonia compounds, separation methods, etc., can solve the problems of unsatisfactory anti-corrosion effect, high maintenance cost, high cost, etc., and achieve convenient replacement, less investment and quick results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

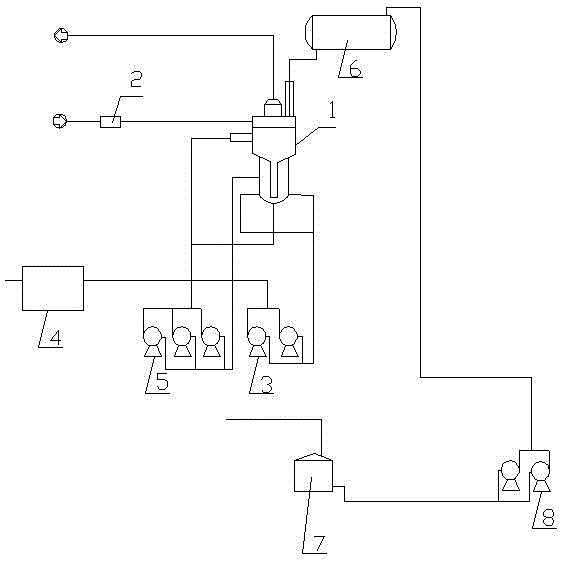

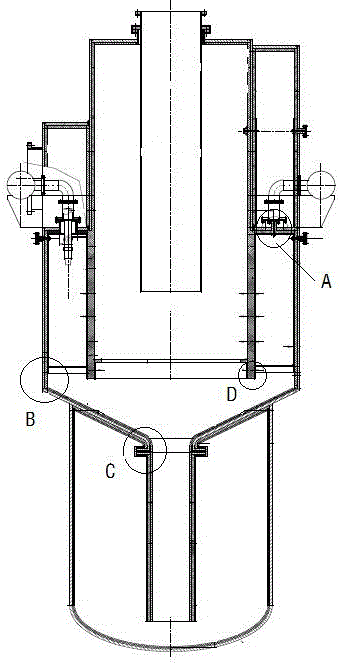

[0033] Such as figure 1 As shown, the saturator method ammonia waste gas treatment device in the present embodiment includes an ammonium sulfate saturator 1, a cooling device 2, a crystallization pump 3, a crystallization tank 4, a circulation pump 5, a sulfuric acid head tank 6, a mother liquor storage tank 7 and Mother liquor spray pump 8;

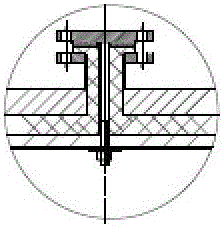

[0034] The cooling device 2 is arranged on the ammonia waste gas intake pipeline of the ammonium sulfate saturator 1; The spray port is connected;

[0035] A mother liquor reflux outlet is arranged on the upper part of the crystallization chamber of the lower section of the ammonium sulfate saturator 1, and a mother liquor reflux inlet is arranged in the spray chamber of the upper section of the ammonium sulfate saturator 1, and a return pipeline is arranged between the two, and a circulation pump 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com