Method for treating livestock and poultry breeding waste water

A technology for sewage treatment and livestock and poultry breeding, applied in the field of livestock and poultry breeding sewage treatment, can solve the problems of difficulty in meeting the discharge requirements of effluent CODcr, low removal of ammonia nitrogen, total nitrogen and total phosphorus, and difficulty in operation and management. Nitrate accumulation, saving carbon source, and stable biogas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The aquaculture sewage of Yulin Company, a Guangdong aquaculture group, discharges 150 tons of aquaculture sewage per day. The main pollutants of the sewage are CODcr 6000-12000mg / L, ammonia nitrogen 650-1100mg / L, SS 5000-12000mg / L, and pH 6-8.5 .

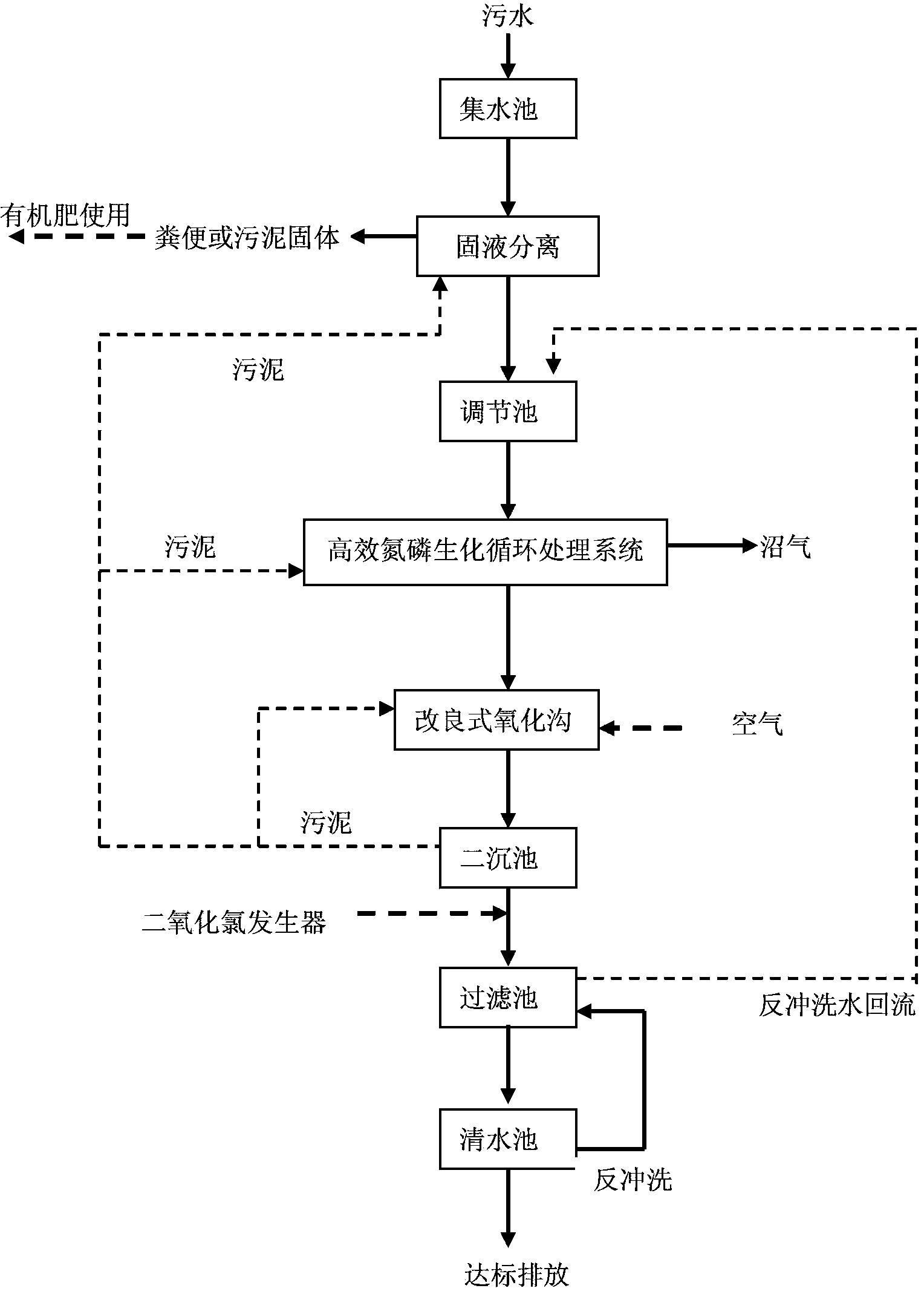

[0036] The treatment technology process is: solid-liquid separation treatment + high-efficiency nitrogen and phosphorus biochemical cycle treatment + improved oxidation ditch treatment + sludge return treatment + filtration disinfection treatment.

[0037] The specific process parameters are:

[0038] 1. The sewage in the sump is pumped into the solid-liquid separator for separation of slag and water, so that the moisture content of the filter residue is 65%-80%, and the filtrate flows into the regulating pool by itself. The volume of the regulating pool is designed to be 150m 3 .

[0039] 2. The sewage in the adjustment tank is quantitatively lifted by the water pump and enters the high-efficiency nitrogen and phosphorus ...

Embodiment 2

[0046] A breeding company in Yanshan County, Yunnan Province discharges 250 tons of breeding wastewater per day. The main pollutants in the wastewater are CODcr 8000-15000mg / L, ammonia nitrogen 850-1200mg / L, SS 5000-12000mg / L, and pH 6- 8.2.

[0047] The processing technique is the same as in Example 1.

[0048] The specific process parameters are:

[0049] 1. The sewage in the sump is separated from slag and water by two solid-liquid separators, so that the water content of the filter residue is 50%-75%, and the filtrate flows into the regulating tank by itself. The volume of the regulating tank is designed to be 250m 3 .

[0050] 2. The sewage in the adjustment tank is quantitatively lifted by the water pump and enters the high-efficiency nitrogen and phosphorus biochemical cycle treatment system, with a total volume of 960m 3 . First, the sewage enters the mixing zone, denitrification zone and sedimentation zone of the denitrification unit sequentially. The reaction tim...

Embodiment 3

[0057] A breeding company in Yulin discharges 60 tons of breeding sewage per day. The main pollutants in the sewage are CODcr 5000-8000mg / L, ammonia nitrogen 600-1000mg / L, SS 5000-8000mg / L, and pH 6-8.

[0058] The processing technique is the same as in Example 1.

[0059] The specific process parameters are:

[0060] 1. The sewage in the sump is pumped into the solid-liquid separator for separation of slag and water, so that the moisture content of the filter residue is 60%-80%, and the filtrate flows into the regulating pool by itself. The volume of the regulating pool is designed to be 60m 3 .

[0061] 2. The sewage in the adjustment tank is quantitatively lifted by the water pump and enters the high-efficiency nitrogen and phosphorus biochemical cycle treatment system, with a total volume of 350m 3 . Firstly, the sewage enters the mixing zone, denitrification zone and sedimentation zone of the denitrification unit sequentially. The reaction time in the mixing zone is 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com