Method and equipment for standards-reaching treatment of chemical nickel plating waste liquid

A technology of electroless nickel plating and treatment methods, applied in chemical instruments and methods, metallurgical wastewater treatment, water/sewage multi-stage treatment, etc., can solve problems such as water eutrophication, heavy metal pollution, resource waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

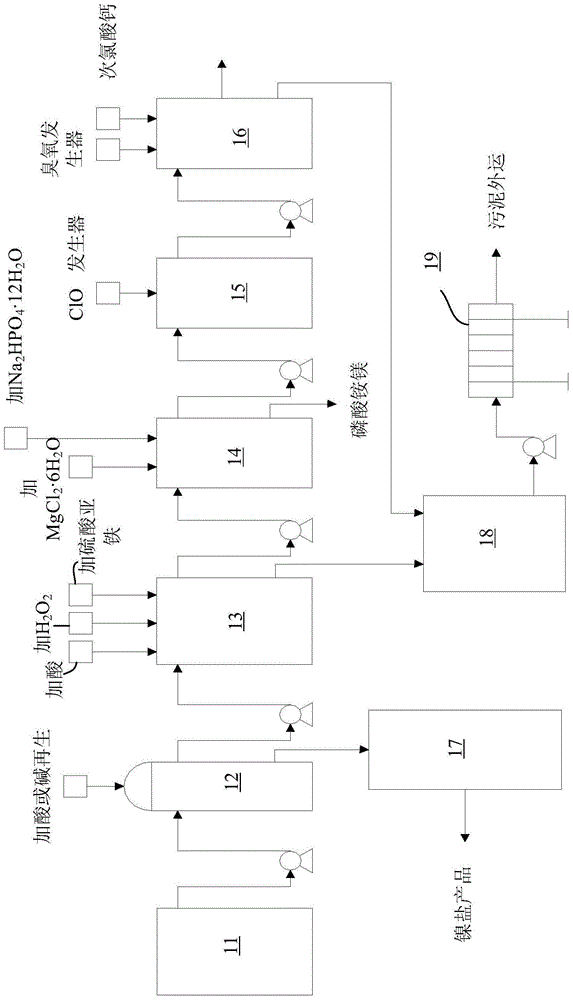

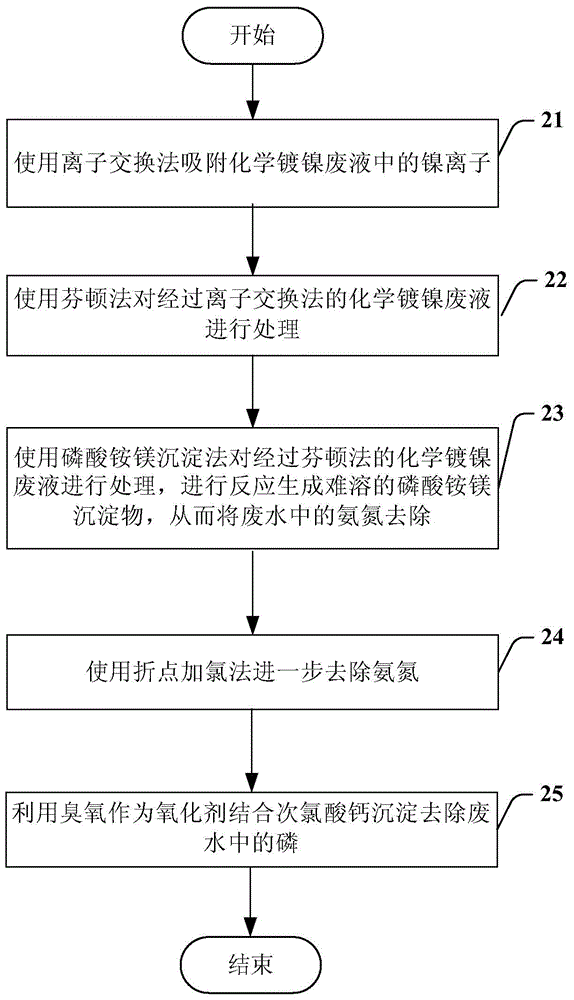

Method used

Image

Examples

Embodiment

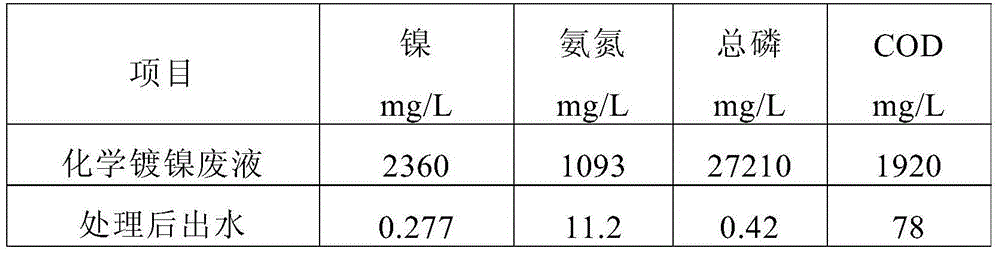

[0058] Take the waste liquid of electroless nickel plating from an enterprise, first use chelating ion exchange resin to absorb nickel, then add 6g of ferrous sulfate + 3ml of hydrogen peroxide per liter of waste liquid, and react for 1 hour. Then add MgCl according to 1.5 times the theoretical dosage 2 ·6H 2 O and Na 2 HPO 4 12H 2 O precipitating agent, control the reaction pH at 8.0-9.0, fully stir the reaction for 20 minutes, precipitate and filter; then add sodium hypochlorite according to the Cl / N mass ratio of 10:1, and keep stirring, stand for 15min after the reaction, precipitate and filter, and obtain supernatant. First pass 80 mg / L ozone into the supernatant for 10 hours, then at a pH of 9 and a temperature of 80°C, make the ratio of calcium to phosphorus 5:1, keep stirring for 5 hours, let stand for 15 minutes, precipitate and filter to obtain the above The supernatant was tested.

[0059]

[0060] The electroless nickel plating waste liquid standard treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com