Dedusting system for flue gas ammonia desulphurization and application method of dedusting system

A dust removal system, ammonia desulfurization technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of ammonia desulfurization users can not run long-term, stable operation, unstable operation, wear and tear of the piping system, etc. Solve the problem of up-to-standard emission of smoke and dust, ensure long-term stable operation, and improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

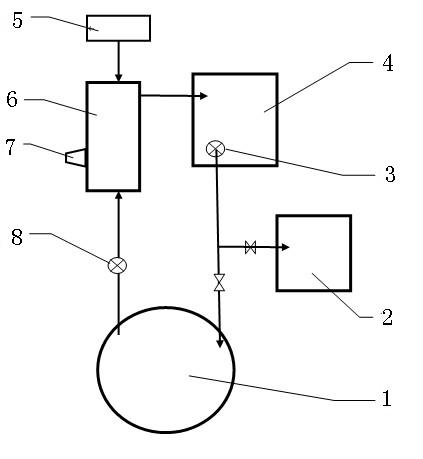

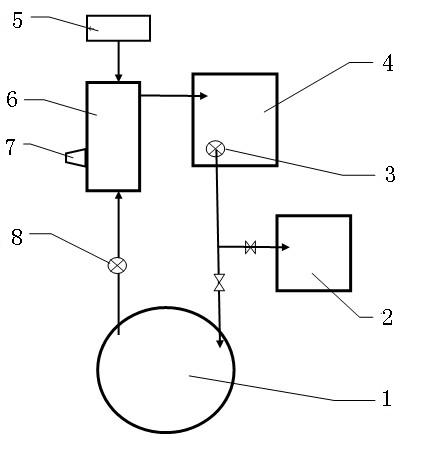

[0026] The dedusting system includes a desulfurization tower 1, a slurry pump 8, a horizontal screw centrifuge 6, a clear liquid pool 4, a clear liquid pump 3, an electric control system 5, and an evaporation concentration system 2. The above desulfurization tower 1, slurry pump 8, horizontal The horizontal screw centrifuge 6 and the clear liquid pump 3 located in the clear liquid pool 4 are connected in series through pipelines to form a closed loop; the horizontal screw centrifuge 6 is connected with an electric control system 5, which controls the horizontal In order to start and run the horizontal screw centrifuge 6, the horizontal screw centrifuge 6 is also provided with a mud outlet 7, through which the sludge deposited in the horizontal screw centrifuge 6 is discharged; the clear liquid pump 3 and An evaporation and concentration system 2 is connected to the pipeline between the desulfurization towers 1 .

[0027] The main principle of flue gas ammonia desulfurization i...

Embodiment 2

[0032] The dedusting system includes a desulfurization tower 1, a slurry pump 8, a horizontal screw centrifuge 6, a clear liquid pool 4, a clear liquid pump 3, an electric control system 5, and an evaporation concentration system 2. The above desulfurization tower 1, slurry pump 8, horizontal The type screw centrifuge 6 and the clear liquid pump 3 located in the clear liquid pool 4 are connected in series through pipelines to form a closed loop; the horizontal screw centrifuge 6 is connected with an electric control system 5, and the horizontal screw centrifuge 6 is There is also a mud outlet 7; the pipeline between the clear liquid pump 3 and the desulfurization tower 1 is connected with an evaporation concentration system 2.

[0033] The main principle of flue gas ammonia desulfurization is to combine ammonia water with SO in boiler flue gas 2 In the desulfurization tower, the reaction produces (NH 4 ) 2 SO 3 , (NH 4 ) 2 SO 3 with O 2 combined to form a more stable (N...

Embodiment 3

[0037] The dedusting system includes a desulfurization tower 1, a slurry pump 8, a horizontal screw centrifuge 6, a clear liquid pool 4, a clear liquid pump 3, an electric control system 5, and an evaporation concentration system 2. The above desulfurization tower 1, slurry pump 8, horizontal The type screw centrifuge 6 and the clear liquid pump 3 located in the clear liquid pool 4 are connected in series through pipelines to form a closed loop; the horizontal screw centrifuge 6 is connected with an electric control system 5, and the horizontal screw centrifuge 6 is There is also a mud outlet 7; the pipeline between the clear liquid pump 3 and the desulfurization tower 1 is connected with an evaporation concentration system 2.

[0038] The main principle of flue gas ammonia desulfurization is to combine ammonia water with SO in boiler flue gas 2 In the desulfurization tower, the reaction produces (NH 4 ) 2 SO 3 , (NH 4 ) 2 SO 3 with O 2 combined to form a more stable (N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com