Method for concentrating CMP (chemi-mechanical pulp) waste liquid by using membrane process

A treatment method and technology of chemical-mechanical pulp, which is applied in the field of membrane concentration treatment of chemical-mechanical pulp waste liquid, can solve the problems of high energy consumption for evaporation and concentration, membrane pollution, and difficulty in discharging chemical-mechanical pulp waste liquid up to the standard, and achieve energy consumption Reduced, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

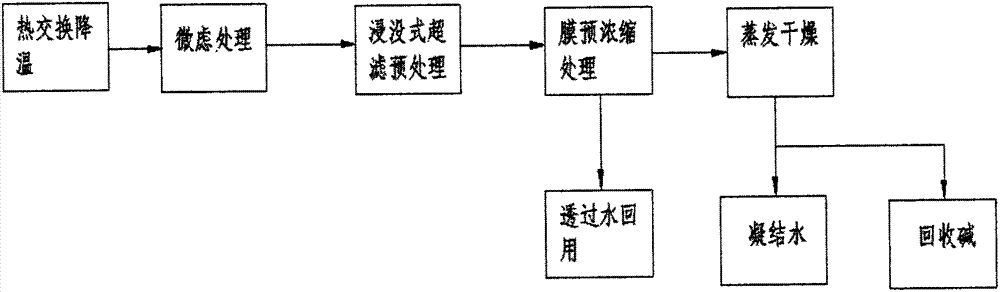

[0024] Such as figure 1 As shown, it is a schematic diagram of the process flow of the membrane concentration treatment of chemical and mechanical pulp waste liquid according to the present invention, including: heat exchange cooling, microfiltration treatment, submerged ultrafiltration pretreatment and membrane preconcentration treatment.

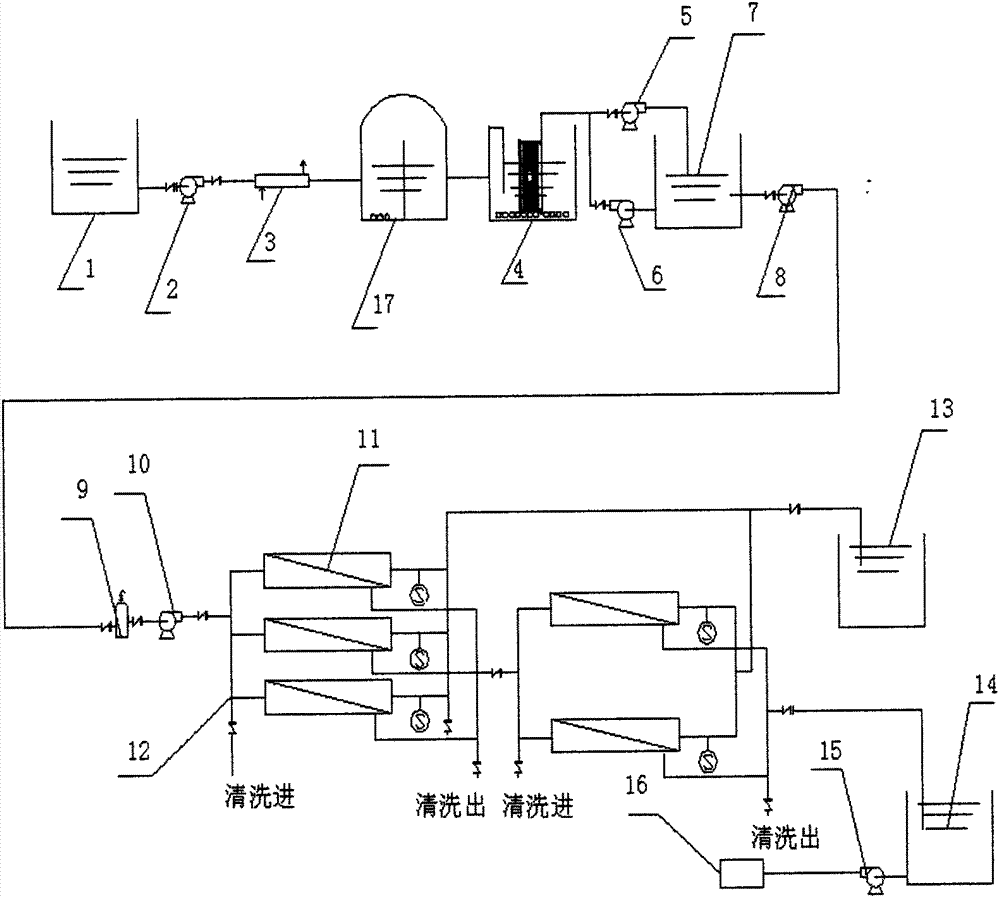

[0025] Such as figure 2 As shown, it is a schematic diagram of a process flow device of a membrane concentration treatment method for chemical pulp waste liquid according to the present invention, including a raw water pool 1, a first booster pump 2, and a stainless steel spiral plate heat exchanger connected in sequence 3. Microfiltration device 17, submerged ultrafiltration membrane equipment 4, self-priming pump 5, backwash pump 6, intermediate pool 7, second booster pump 8, security filter 9, high-pressure pump 10, reverse osmosis or nanofiltration equipment 11. Flushing device 12, water production tank 13, concentrated water tank 14...

Embodiment 2

[0028] Process flow and apparatus schematic diagram are as embodiment 1.

[0029]The first booster pump 2 extracts the chemical-mechanical pulp waste liquid from the raw water pool 1, the extraction amount is 100 tons / hour, the pressure is 0.3MPa, and it enters the stainless steel spiral plate heat exchanger 3. At this time, the temperature of the chemical-mechanical pulp waste liquid is 48 °C, the mass percentage concentration is 2%, the waste liquid is cooled through the spiral plate heat exchanger 3, and the outlet water temperature after the heat exchanger treatment is 27 °C. Then enter the microfiltration equipment 17, the microfiltration filtration accuracy is 200 microns, and then enter the submerged ultrafiltration membrane equipment 4, and the submerged ultrafiltration membrane equipment 4 has 4 sets (one of them is spare), and each set of water production is 92 tons / hour , the submerged ultrafiltration equipment 4 has an operating pressure of minus 3 standard atmosph...

Embodiment 3

[0031] Process flow and device schematic diagram are as embodiment 1.

[0032] The first booster pump 2 extracts the chemical-mechanical pulp waste liquid from the raw water pool 1, the extraction amount is 100 tons / hour, the pressure is 0.3MPa, and enters the stainless steel spiral plate heat exchanger 3. At this time, the temperature of the chemical-mechanical pulp waste liquid is 45 °C, the mass percentage concentration is 1.5%, the waste liquid is cooled through the spiral plate heat exchanger 3, and the outlet water temperature after the heat exchanger treatment is 30 °C. Then enter the microfiltration equipment 17, the microfiltration filtration precision is 100 microns, and then enter the submerged ultrafiltration membrane equipment 4, and the submerged ultrafiltration membrane equipment 4 has 4 sets (one of them is spare), and each set of water production is 92 tons / hour , the operating pressure of the submerged ultrafiltration equipment 4 is minus 1 standard atmospher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com