A double-tower catalytic thermal coupling countercurrent deamination method and its deamination device

A thermal coupling and deamination technology, applied in the field of deamination treatment, can solve the problems of high cost of treatment chemicals, high investment, strict requirements for pretreatment effluent, etc., achieve significant environmental and social benefits, overcome the large amount of liquid spray, The effect of solving the problem of up-to-standard emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

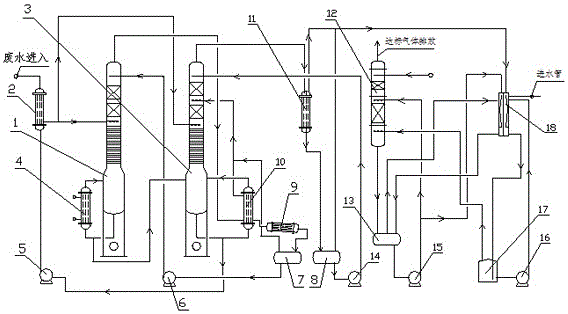

Image

Examples

Embodiment Construction

[0028] a. Add a pH regulator (equivalently a neutralizer, such as hydrochloric acid, sodium hydroxide, potassium hydroxide, sodium carbonate and ammonia water, etc.) and a compound ammonia solution agent (such as ammonia water and liquid chlorine, etc.) into the ammonia nitrogen wastewater buffer pool , add 60g~80g compound ammonia solution agent to one cubic meter of wastewater to adjust the pH value of ammonia nitrogen wastewater to 10.5~11.5;

[0029] b. Preheat the ammonia nitrogen wastewater treated in step a to 40-50°C through the wastewater preheater,

[0030] c, a part of ammonia nitrogen waste water after step b preheating is sent into the heat pressurization tower middle section and fully contacts with the hot steam that rises in the heat pressurization tower produced by the heat pressurization tower reboiler, and described heating steam pressure is 0.6Mpa, and then send the ammonia-containing steam generated at the top of the hot pressurized tower to the reboiler of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com