Dedusting system for flue gas ammonia desulphurization and application method of dedusting system

A dust removal system and ammonia desulfurization technology, which is applied in the field of ammonia desulfurization system and flue gas ammonia desulfurization dust removal system, can solve the problems of ammonia desulfurization users who cannot operate stably for a long time, run unstable, and wear and tear of piping systems. To achieve the effect of solving the problem of smoke and dust emission standards, ensuring long-term stable operation, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

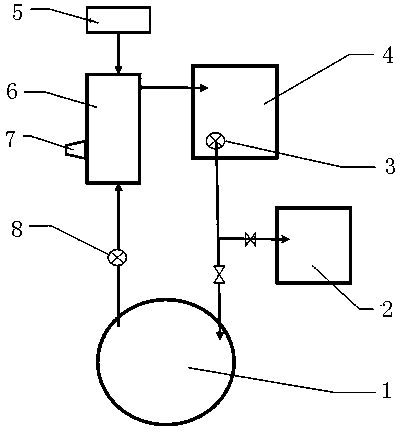

[0026] The dedusting system includes a desulfurization tower 1, a slurry pump 8, a horizontal screw centrifuge 6, a clear liquid pool 4, a clear liquid pump 3, an electric control system 5, and an evaporation concentration system 2. The above desulfurization tower 1, slurry pump 8, horizontal The horizontal screw centrifuge 6 and the clear liquid pump 3 located in the clear liquid pool 4 are connected in series through pipelines to form a closed loop; the horizontal screw centrifuge 6 is connected with an electric control system 5, which controls the horizontal In order to start and run the horizontal screw centrifuge 6, the horizontal screw centrifuge 6 is also provided with a mud outlet 7, through which the sludge deposited in the horizontal screw centrifuge 6 is discharged; the clear liquid pump 3 and An evaporation and concentration system 2 is connected to the pipeline between the desulfurization towers 1 .

[0027] The main principle of flue gas ammonia desulfurization i...

Embodiment 2

[0032] The dedusting system includes a desulfurization tower 1, a slurry pump 8, a horizontal screw centrifuge 6, a clear liquid pool 4, a clear liquid pump 3, an electric control system 5, and an evaporation concentration system 2. The above desulfurization tower 1, slurry pump 8, horizontal The type screw centrifuge 6 and the clear liquid pump 3 located in the clear liquid pool 4 are connected in series through pipelines to form a closed loop; the horizontal screw centrifuge 6 is connected with an electric control system 5, and the horizontal screw centrifuge 6 is There is also a mud outlet 7; the pipeline between the clear liquid pump 3 and the desulfurization tower 1 is connected with an evaporation concentration system 2.

[0033] The main principle of flue gas ammonia desulfurization is to combine ammonia water with SO in boiler flue gas 2 In the desulfurization tower, the reaction produces (NH 4 ) 2 SO 3 , (NH 4 ) 2 SO 3 with O 2 combined to form a more stable (N...

Embodiment 3

[0037] The dedusting system includes a desulfurization tower 1, a slurry pump 8, a horizontal screw centrifuge 6, a clear liquid pool 4, a clear liquid pump 3, an electric control system 5, and an evaporation concentration system 2. The above desulfurization tower 1, slurry pump 8, horizontal The type screw centrifuge 6 and the clear liquid pump 3 located in the clear liquid pool 4 are connected in series through pipelines to form a closed loop; the horizontal screw centrifuge 6 is connected with an electric control system 5, and the horizontal screw centrifuge 6 is There is also a mud outlet 7; the pipeline between the clear liquid pump 3 and the desulfurization tower 1 is connected with an evaporation concentration system 2.

[0038] The main principle of flue gas ammonia desulfurization is to combine ammonia water with SO in boiler flue gas 2 In the desulfurization tower, the reaction produces (NH 4 ) 2 SO 3 , (NH 4 ) 2 SO 3 with O 2 combined to form a more stable (N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com