Treatment method of high-salt content and refractory oil exploitation wastewater

A technology for oil extraction and treatment methods, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. problem, to avoid secondary pollution, high oxidation efficiency, good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

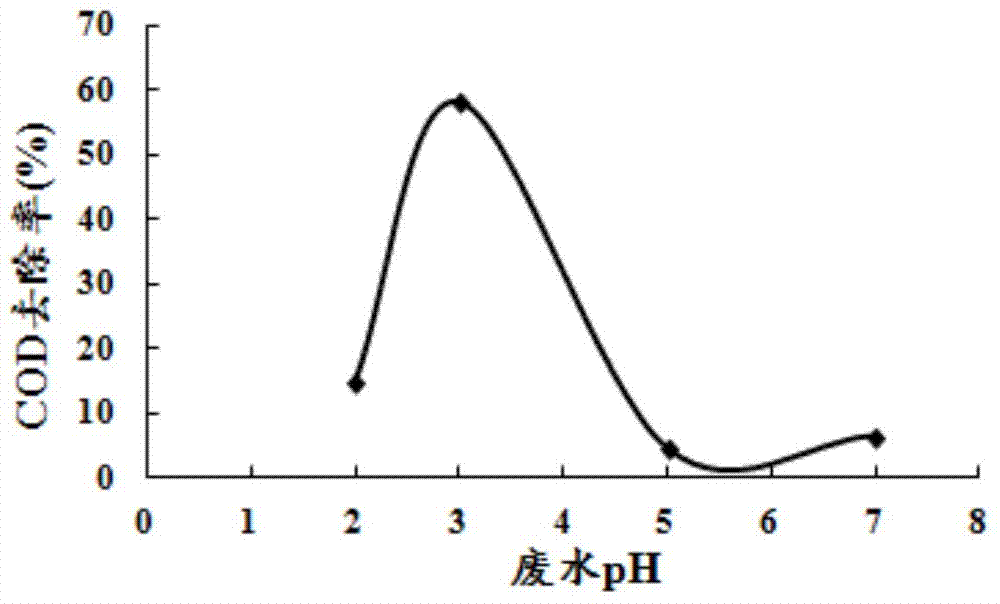

Embodiment 1

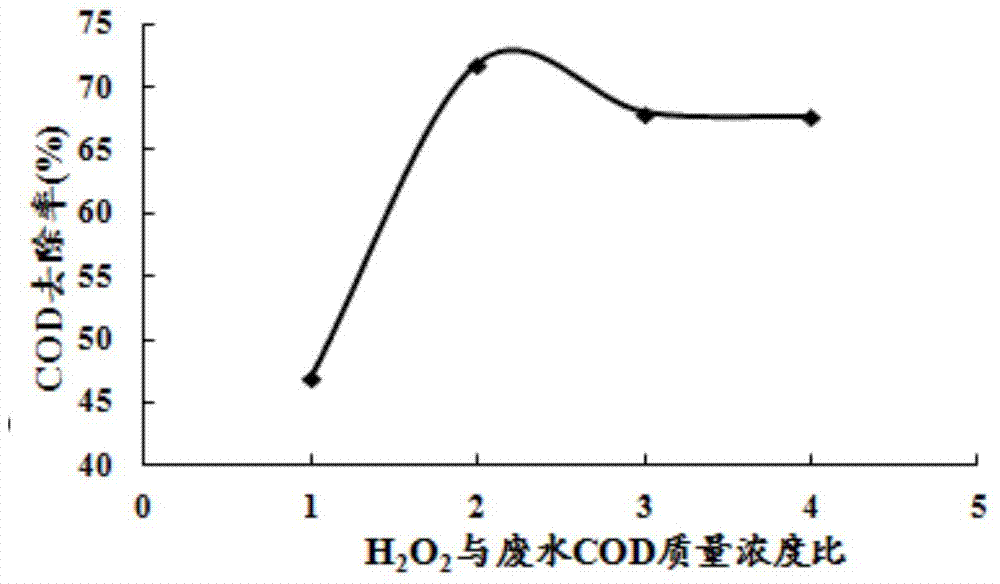

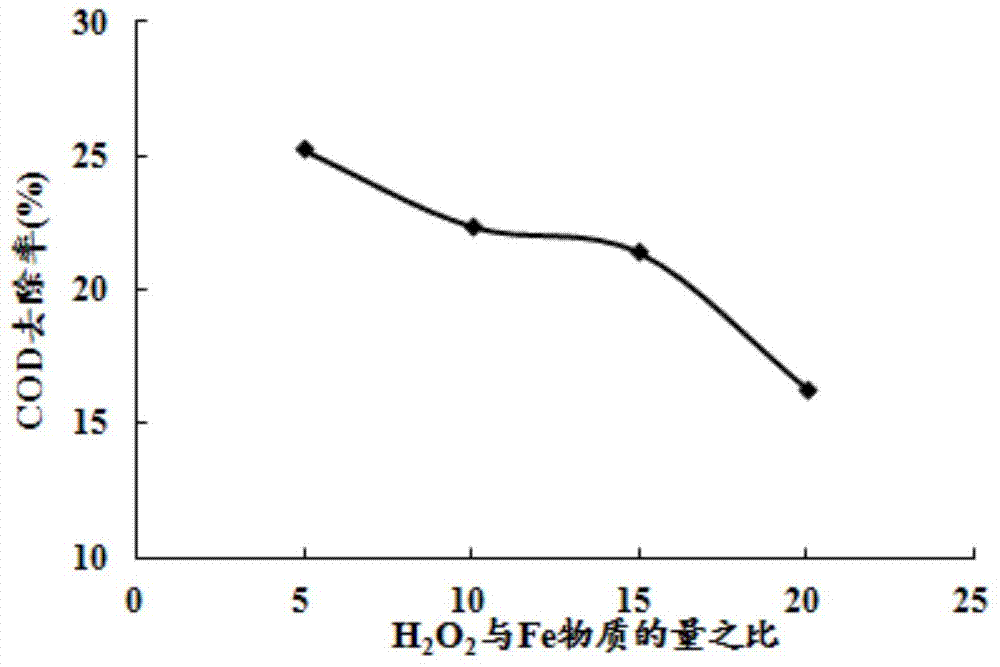

[0036] Control c (H 2 o 2 ) / c(COD) mass concentration ratio=1:1, n(H 2 o 2 ) / n (Fe) material ratio = 10:1, the pH of the waste water is 2 (add a small amount of waste acid to adjust the pH in advance, other embodiments are the same as this requirement), the COD is 250mg / L, and the turbidity is 30NTU. Add 0.066g of ferrous sulfate solid to the mining wastewater, stir at a speed of 200r / min until it dissolves, then add 120μL of hydrogen peroxide liquid with a mass concentration of 30%, react at natural temperature for 30min, and take the supernatant for COD detection .

Embodiment 2

[0038] The difference between embodiment 2 and embodiment 1 is that the pH of the waste water is pre-adjusted to 3, and the others are the same as embodiment 1.

Embodiment 3

[0040] The difference between embodiment 3 and embodiment 1 lies in that the pH of the waste water is pre-adjusted to 5, and the others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com