Electroplating wastewater processing technology and special-purpose apparatus thereof

A technology for treating process and electroplating wastewater, applied in metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of high treatment cost, secondary pollution, poor treatment effect, etc. The effect of saving water resources and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

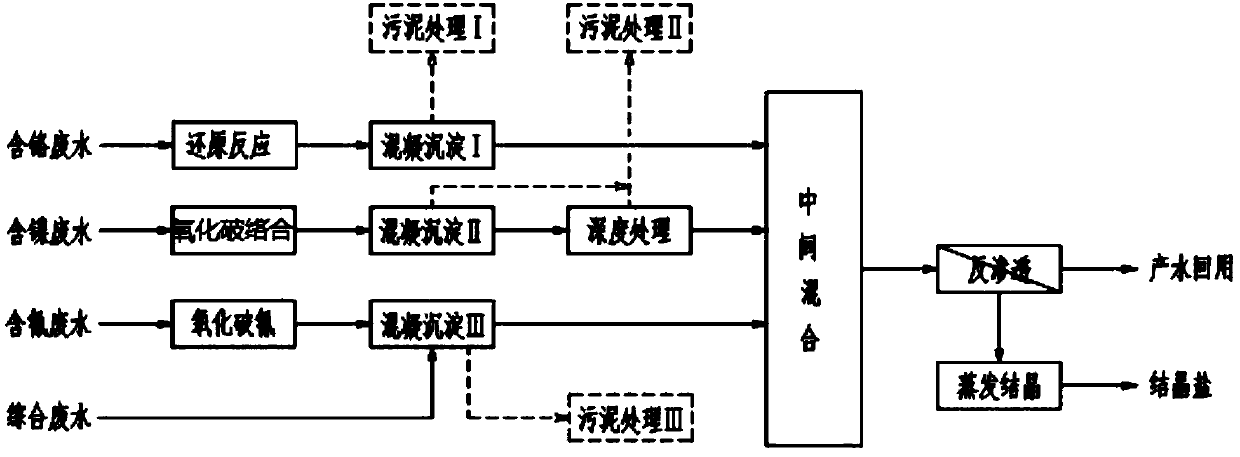

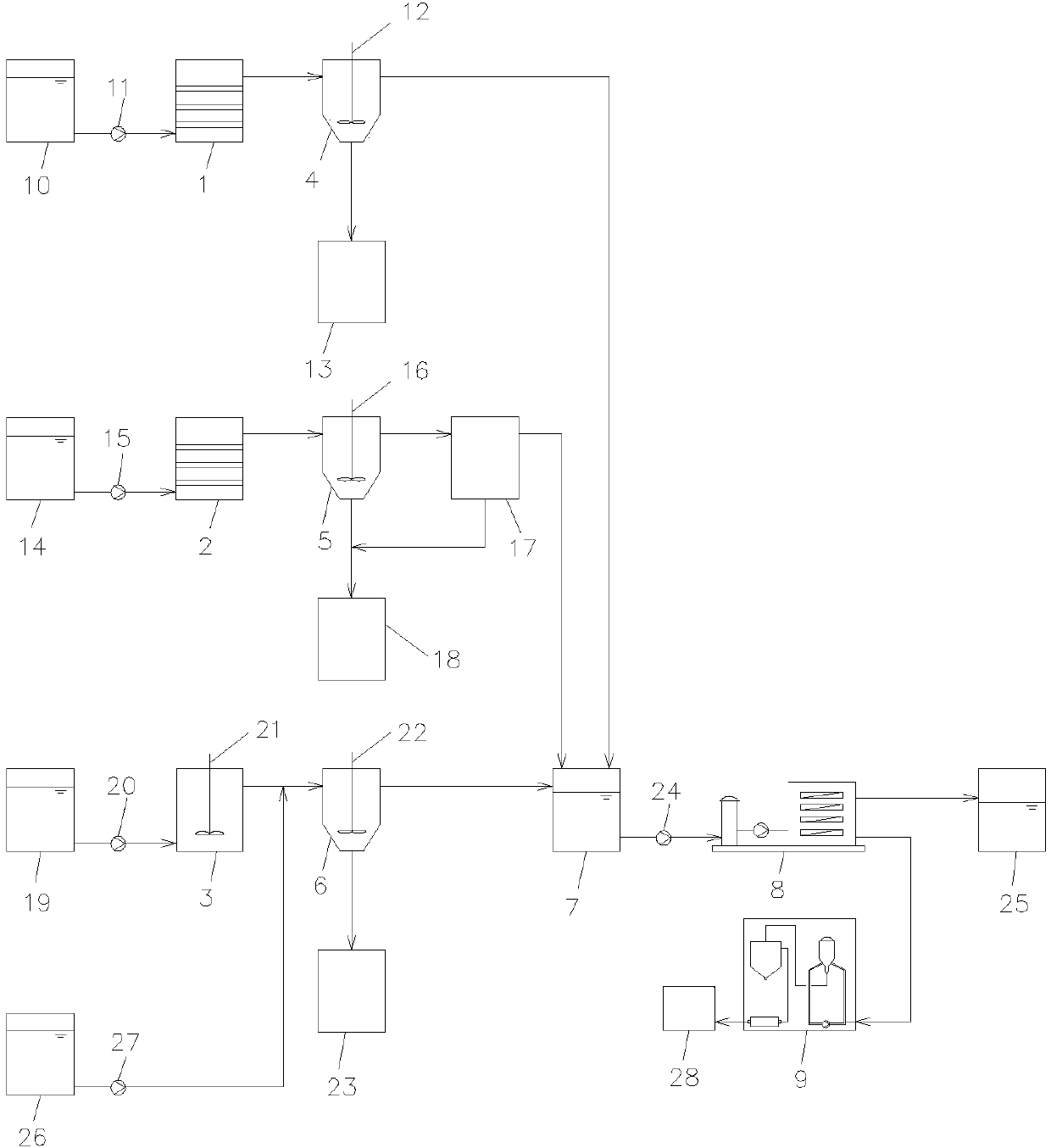

[0038] As attached figure 2 As shown, the special device for electroplating wastewater treatment process includes a reduction reactor 1, a decomplexation reactor 2, a cyanide-breaking reactor 3, a first sedimentation tank 4, a second sedimentation tank 5, a third sedimentation tank 6, and an intermediate Mixing tank 7, reverse osmosis unit 8 and evaporation crystallization unit 9;

[0039] The first raw water tank 10 is connected to the reduction reactor 1, a first water inlet pump 11 is installed on the connecting pipeline, the output end of the reduction reactor 1 is connected to the first sedimentation tank 4, and the clear liquid output end of the first sedimentation tank 4 is connected to the middle The mixing tank 7, the sludge output end of the first sedimentation tank 4 is connected to the first sludge treatment system 13;

[0040] The second raw water tank 14 is connected to the decomplexation reactor 2, a second water inlet pump 15 is installed on the connecting pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com