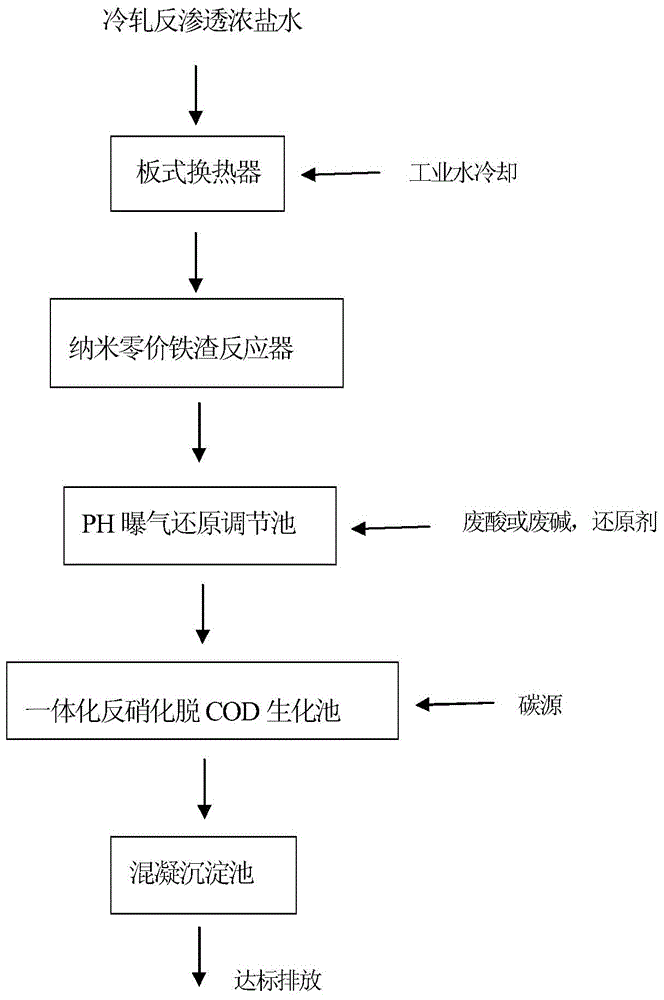

Processing system and method for cold rolling reverse osmosis strong brine

A treatment system and treatment method technology, applied in the field of cold-rolled reverse osmosis concentrated brine treatment system, can solve the problems of low production and treatment costs, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

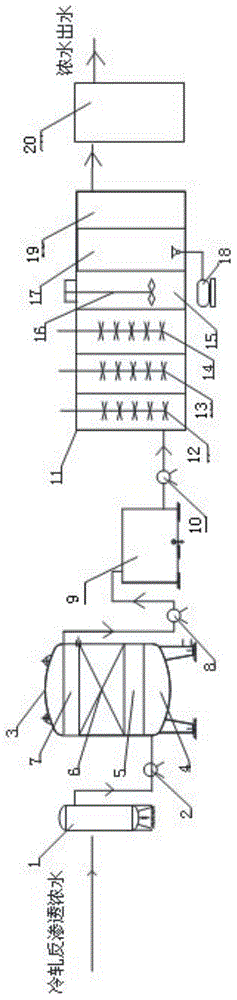

[0092] The water quality of cold rolling waste water reverse osmosis concentrated brine in embodiment 1: conductivity is 16000 μ S / cm, and chloride ion is 3570 mg / L, and sulfate ion is 653 mg / L, and pH is 4, and total nitrogen is 91 mg / L, and nitrate nitrogen is 67mg / L, ammonia nitrogen 18mg / L, COD 270mg / L, BOD 45mg / L, total iron 15mg / L, total nickel 1.8mg / L, total zinc 2.4mg / L, total chromium 0.4mg / L, the total lead is 0.5mg / L, the total copper is 0.5mg / L, and the water temperature is 47 degrees.

[0093] The cold-rolled reverse osmosis concentrated water enters the plate heat exchanger, and the outlet water temperature is controlled between 23 degrees.

[0094] Then enter the nano zero-valent iron slag reactor. The volume ratio of quartz sand accounting for the filter material in the nanometer zero-valent iron slag reactor filter layer in this example is 10%, water slag is 10%, nanometer zero-valent iron slag is 60%, and calcium-based modified bentonite is 20%. %. The fl...

Embodiment 2

[0109] The water quality of cold rolling waste water reverse osmosis strong brine in embodiment 2: electric conductivity is 13000 μ S / cm, and chloride ion is 2890 mg / L, and sulfate ion is 613 mg / L, and pH is 10, and total nitrogen is 56 mg / L, and nitrate nitrogen is 40mg / L, ammonia nitrogen 11mg / L, COD 163mg / L, BOD 29mg / L, total iron 11mg / L, total nickel 1.1mg / L, total zinc 2.1mg / L, total chromium 0.3mg / L, the total lead is 0.3mg / L, the total copper is 0.5mg / L, and the water temperature is 37 degrees.

[0110] The cold-rolled reverse osmosis concentrated water enters the plate heat exchanger, and the outlet water temperature is controlled between 21 degrees.

[0111] Then enter the nano zero-valent iron slag reactor. In the nanometer zero-valent iron slag reactor filter material layer in this example, the volume ratio of quartz sand accounting for the filter material is 15%, water slag is 15%, nanometer zero-valent iron slag is 50%, and calcium-based modified bentonite is 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com