Up-to-standard treatment method and device for zinc-nickel alloy waste water

A zinc-nickel alloy and treatment method technology, which is applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of unfavorable promotion and high treatment cost, and achieve low cost and simple equipment , Solving the effect of meeting emission standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

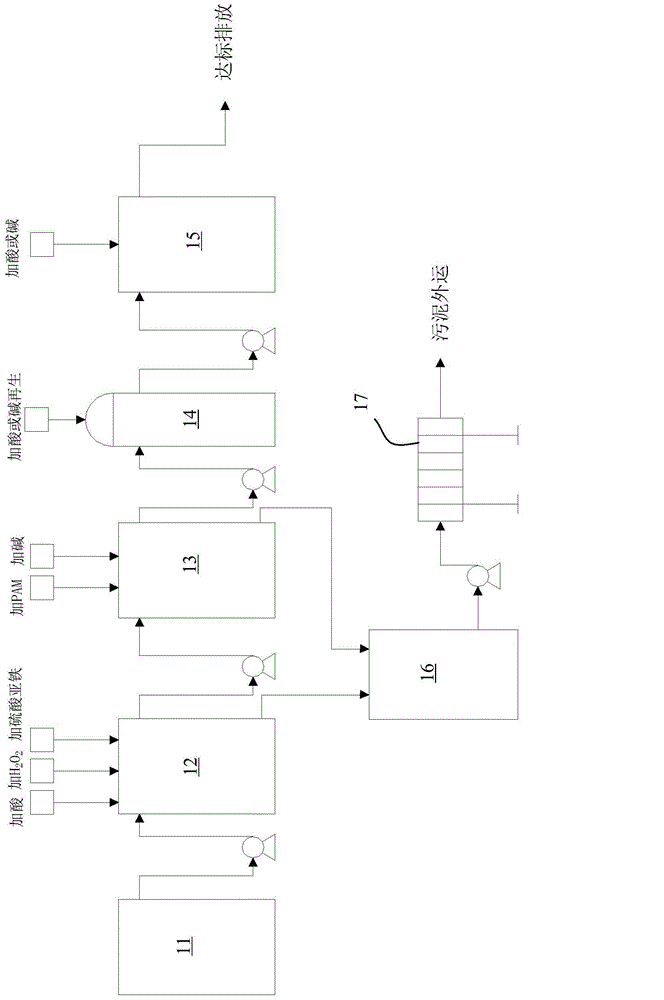

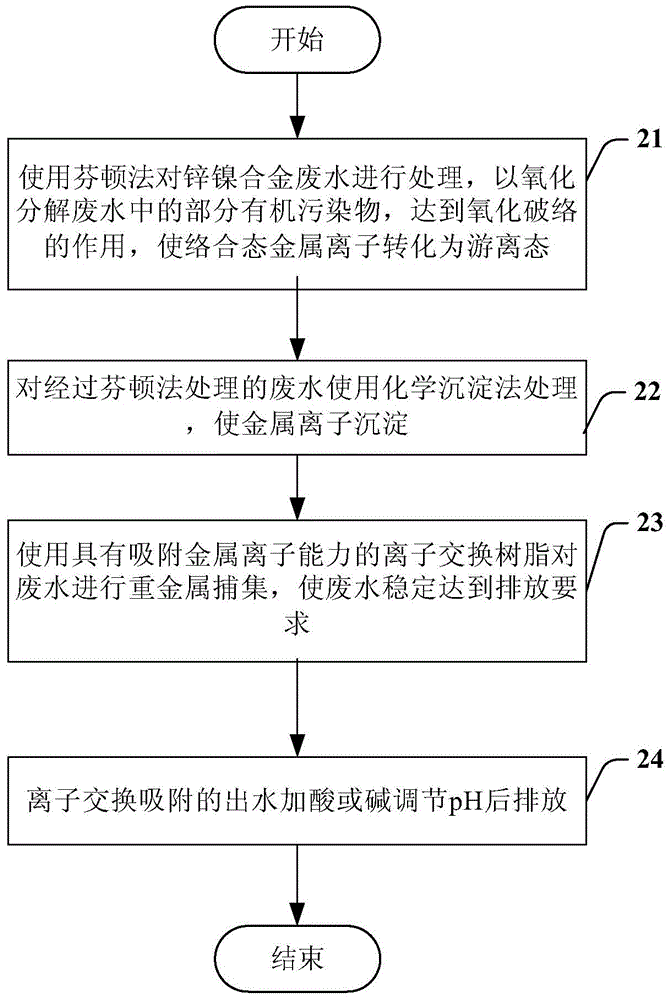

Method used

Image

Examples

example 1

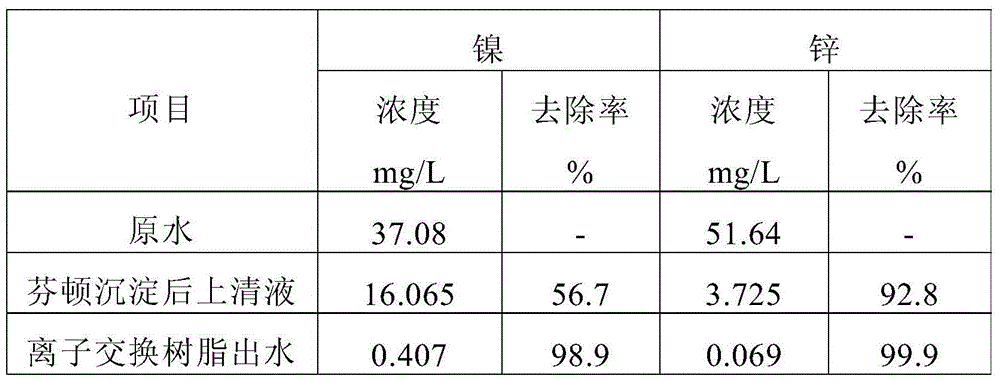

[0038]Take zinc-nickel alloy wastewater from a certain enterprise, adjust pH=2.5, add 1.0g ferrous sulfate + 4ml hydrogen peroxide per liter of wastewater, react for 3 hours, adjust pH to 12 and precipitate, add PAM to filter, take supernatant and pass through ion exchange resin , Determination of nickel and zinc concentrations in treated water.

[0039]

[0040] 1. In addition to using the ferrous / hydrogen peroxide system, the Fenton oxidation technology in this invention can also use the ferrous / ozone system;

[0041] 2. The ion exchange resin in this invention needs to adopt the ion exchange resin with the ability to adsorb metal ions, such as weak acid ion exchange resin, or chelating ion exchange resin, etc.

example 2

[0043] Take zinc-nickel alloy wastewater from a certain enterprise, pH<2.5, directly add 1.5g ferrous sulfate heptahydrate to each liter of wastewater, react for 30min, adjust pH to 9, aerate with ozone for 1h, add PAM to precipitate and filter, supernatant is ion exchanged resin.

[0044] sample name

[0045] raw water

[0046] Therefore, the embodiment of the present invention adopts the combination technology of Fenton oxidation-chemical precipitation-ion exchange adsorption to treat zinc-nickel alloy wastewater, which can solve the problem of discharge of zinc-nickel alloy wastewater up to the standard. This method and its equipment are simple, convenient to operate, low in cost, and have strong practicability. The effluent after zinc-nickel alloy wastewater treatment can stably meet the standards in Table 2 or Table 3 of "Electroplating Pollutant Discharge Standard GB21900-2008".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com