Method and device for treating rare-earth molten high ammonia nitrogen wastewater by using integrated membrane technology

A technical treatment, high ammonia nitrogen technology, applied in the field of integrated membrane technology to treat high ammonia nitrogen wastewater from rare earth smelting, can solve the problems of high production cost, secondary pollution, high cost, etc., and achieve important environmental and economic benefits, pollutant discharge The effect of less quantity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

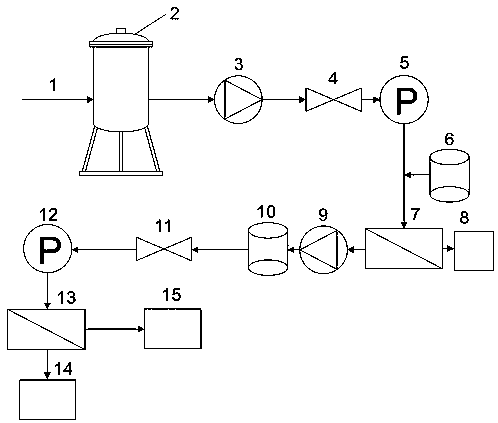

[0034] The specific embodiment of the present invention is as shown in the accompanying drawings.

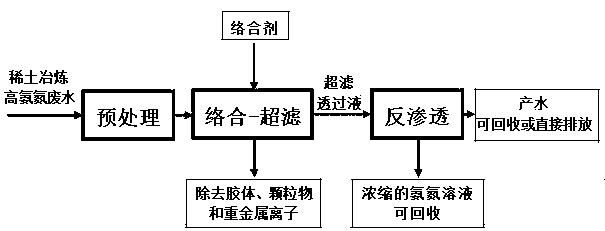

[0035] figure 1 It is a process flow diagram of the present invention. In this embodiment, a method for treating high-ammonia-nitrogen wastewater from rare earth smelting with integrated membrane technology comprises the following steps:

[0036] (1) Pre-removing impurities from rare earth smelting high-ammonia nitrogen wastewater to clarify the rare earth smelting wastewater to obtain clear liquid;

[0037] (2) Processed sequentially through the integrated membrane process consisting of the following membrane process steps:

[0038]Complexation-ultrafiltration coupling: the pretreated rare earth smelting wastewater clear liquid is filtered by ultrafiltration membrane technology to remove colloids and particles larger than 0.1 μm in the wastewater stock solution; the complexed water treatment agent is used to concentrate and recover heavy metals and rare earths to obtain The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com