Composite type multilayer spiral vibrating countercurrent drying machine

A composite, dryer technology, applied in dryers, drying solid materials, drying chambers/containers, etc., can solve the problems of affecting drying effect, difficult to clean and clean, difficult to clean, etc., to achieve convenient cleaning and cleaning, easy to clean Cleaning and cleaning, improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in detail below in conjunction with accompanying drawing:

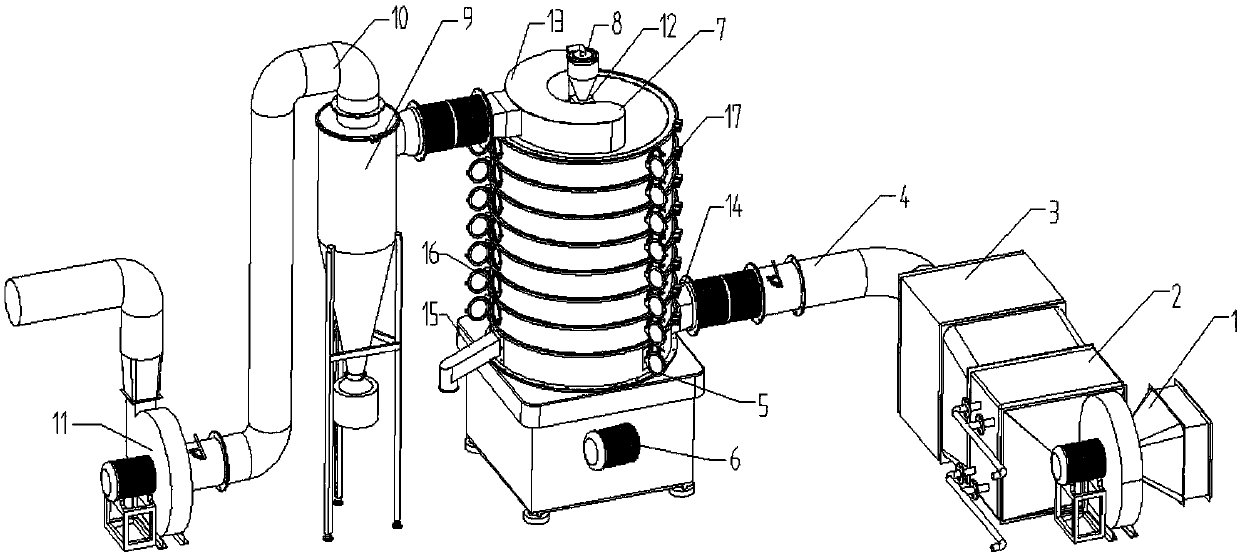

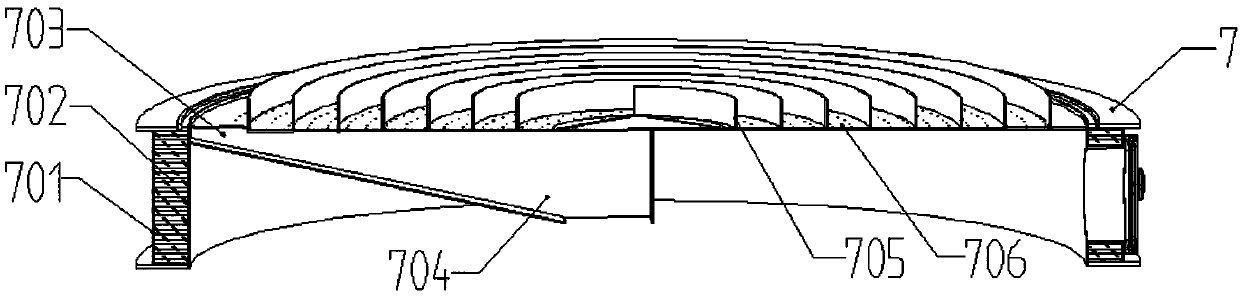

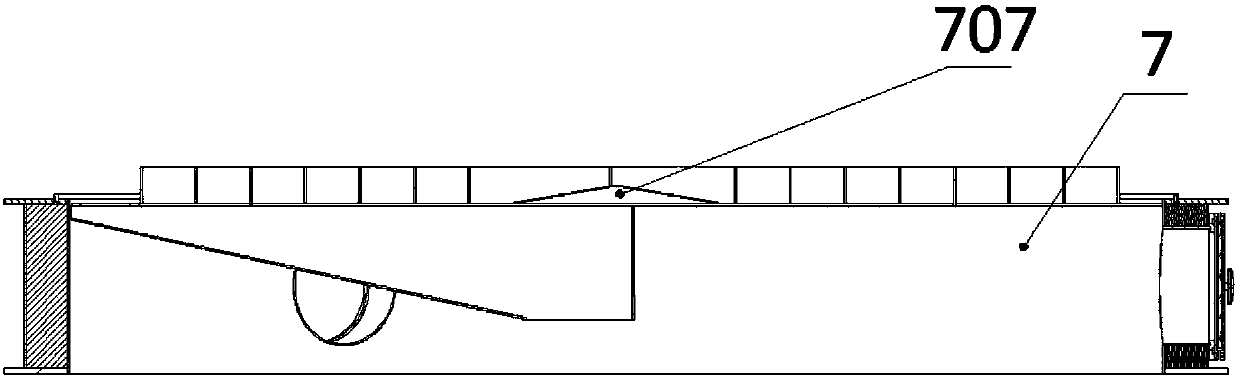

[0021] Such as figure 1 As shown, the composite multi-layer spiral vibration countercurrent dryer includes a base 5, a vibration device 6, a drying plate 7, an automatic feeding device 8, a blower 1, an air filter 3, a heater 2, a dust collector 9, and an induced draft fan 11 , Air inlet pipe 4, air outlet pipe 10 etc. A plurality of drying trays 7 are stacked to form a drying box, and the drying box is installed on the base 5, and the inside of the base 5 is equipped with a vibration motor 6, such as figure 2 As shown, the drying tray 7 includes a box body 701 , an insulating layer 702 , a sieve plate 706 , a spiral piece 705 , a blanking opening 703 , and a blanking chute 704 . The side wall of the box body 701 is provided with an insulating layer 702, and the top of the box body 701 is welded with a sieve plate 706. Blanking trough 704, the upper end of the blanking tro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com