Plate drying room

A drying chamber and plate technology, which is applied in the fields of pretreatment of surfaces, coatings, and devices for coating liquids on surfaces, etc., can solve the problems of difficulty in matching the rhythm of the drying time of the production line, the quality of the coating cannot be guaranteed, and the space occupied is large. The effect of speeding up the drying speed, speeding up the drying of the paint surface and saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

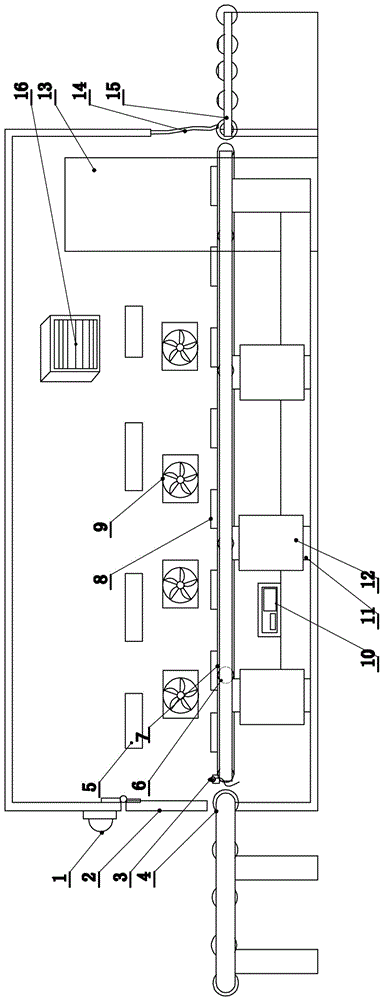

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] The panel drying room consists of a drying room with conveyor belts running along the length of the drying room and running through the room. There are inlets and outlets on the side plates opposite to the two ends of the conveyor belt in the drying room. The outer sides of the entrance and the outlet are respectively provided with a warehouse-in support and a warehouse-out support 15, and some rollers 4 are distributed on the warehouse-out support 15. Roller 4 is consistent with conveyer belt height.

[0014] A plurality of heating plates 12 are distributed on the legs 11 of the conveyor belt or on the wall of the drying room. The heating plates 12 and the temperature sensor are connected to the electrical control box 10, and the heating plates 12 are connected to a constant temperature controller to make the interior of the room dry at a constant temperature....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com