A tea drying device

A tea drying device and tea technology, which are applied in drying, drying machine, tea processing before extraction, etc., can solve the problems of low fuel combustion utilization rate, slow tea drying speed, affecting the operation cost of tea drying equipment, etc. , to achieve the effect of saving resources, retaining the fragrance, and avoiding the phenomenon of dampness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

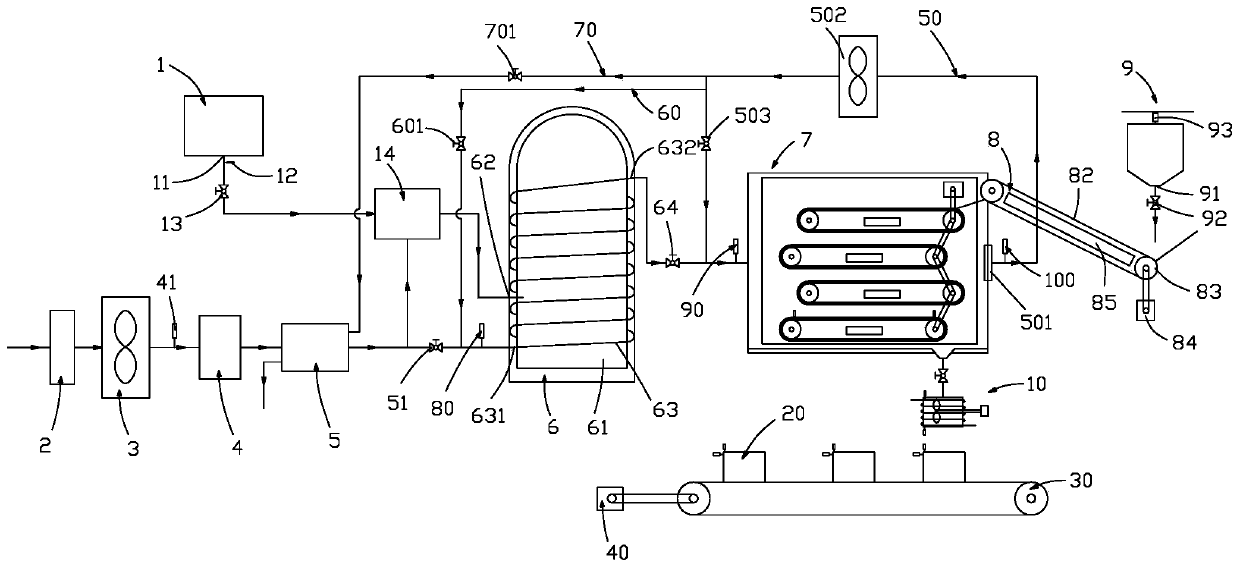

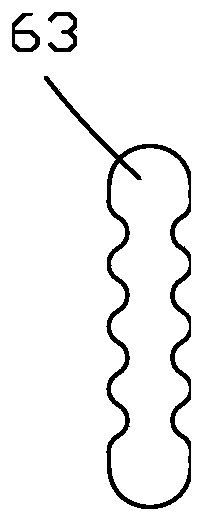

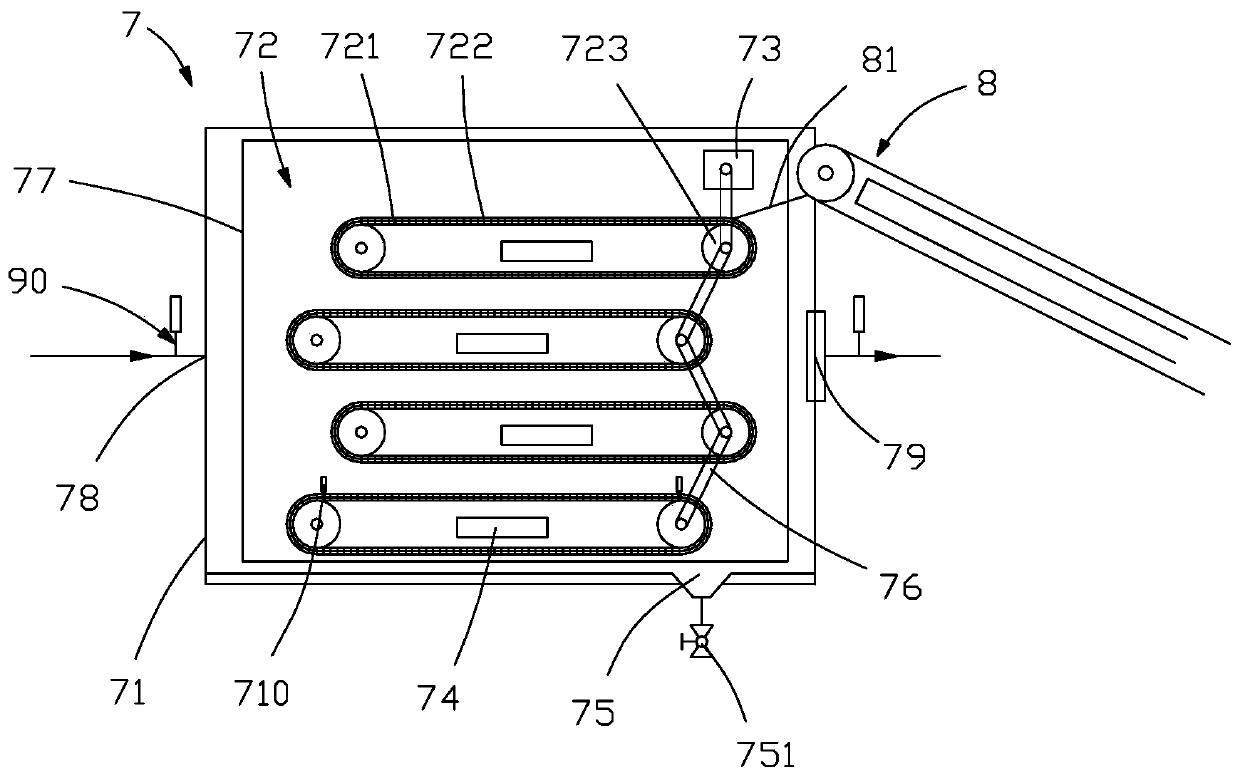

[0031] see Figure 1 to Figure 4 , in a preferred embodiment of the present invention, a tea drying device includes a fuel storage bin 1, a first fan 3, a mixing device 14, a dehumidification device 4, a boiler 6, a drying box 7. A feeding device 8, a leaf storage bin 9, a waste heat device 5, a second fan 502, a tea cooling device 10, a tea collection device 20, a tea collection conveyor belt assembly 30, and a collection motor 40 and a controller. The first fan 3 is connected to the dehumidification device 4, and the dehumidification device 4 and the fuel storage bin 1 are respectively connected to the boiler 6 through the mixing device 14; a combustion chamber 61 is provided in the boiler 6, and a combustion port 62 is opened to communicate with the outside of the combustion chamber 61 , the mixing device 14 is connected to the boiler 6 through the combustion port 62 . A heat exchange tube 63 is arranged on the inner wall of the boiler 6, and the heat exchange tube 63 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com