Processing and mixing equipment for fermenting and purifying high-dietary-fiber feed

A technology of high dietary fiber and mixing equipment, applied in biochemical equipment and methods, bioreactor/fermenter combination, feed and other directions, can solve the problems of non-conforming production standards, inability to mix raw materials, poor quality of dietary fiber feed, etc. Achieve the effect of increasing the mixing range, reducing maintenance costs and time, and ensuring overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

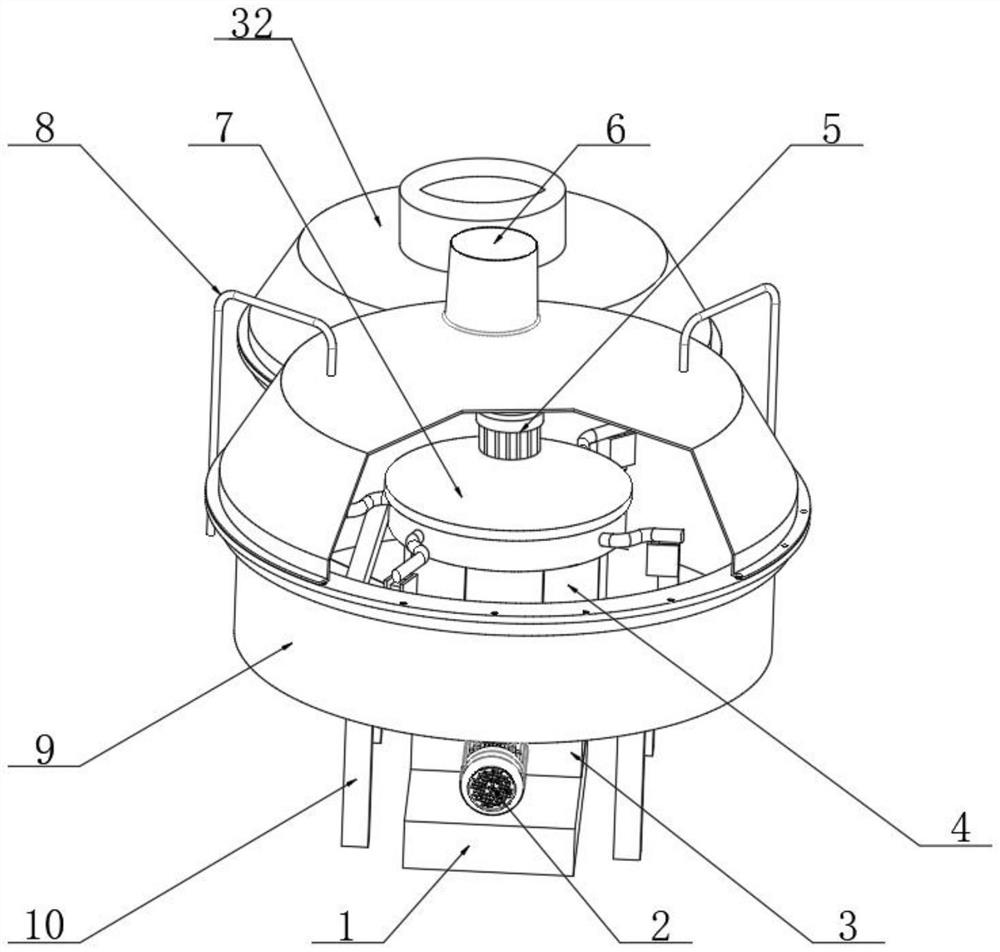

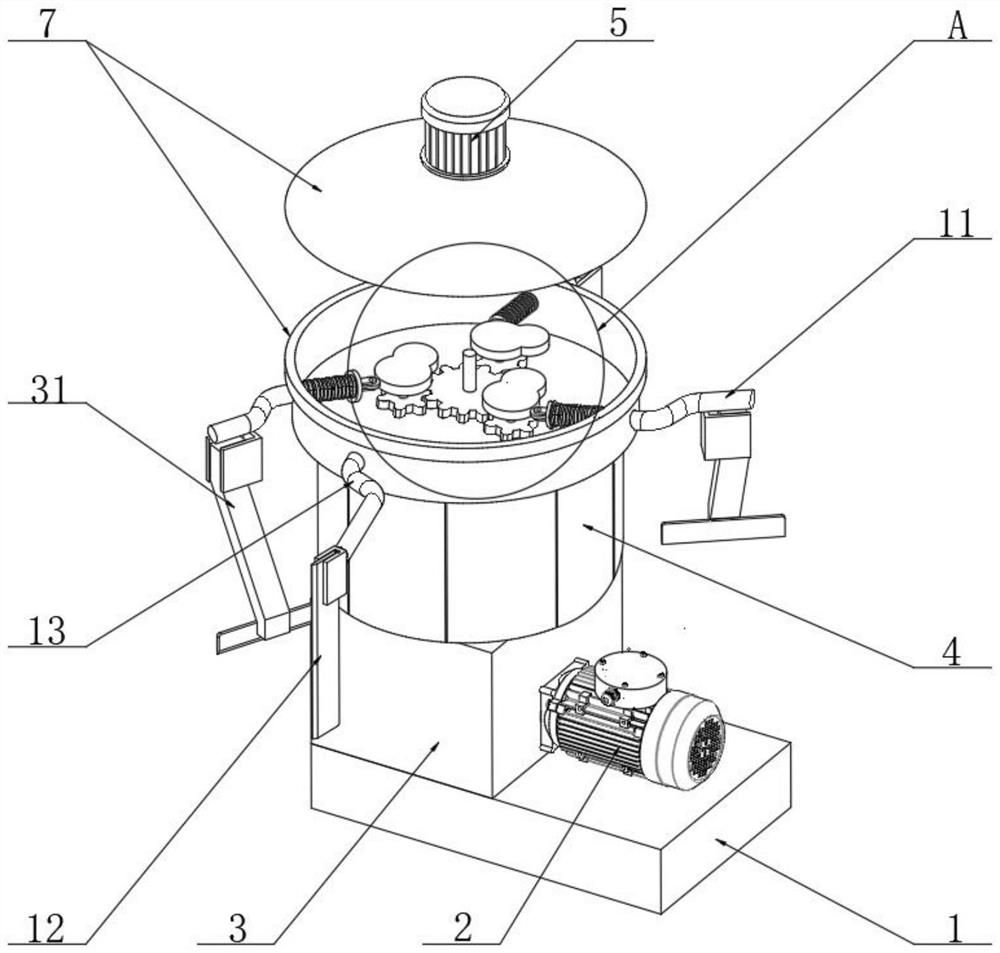

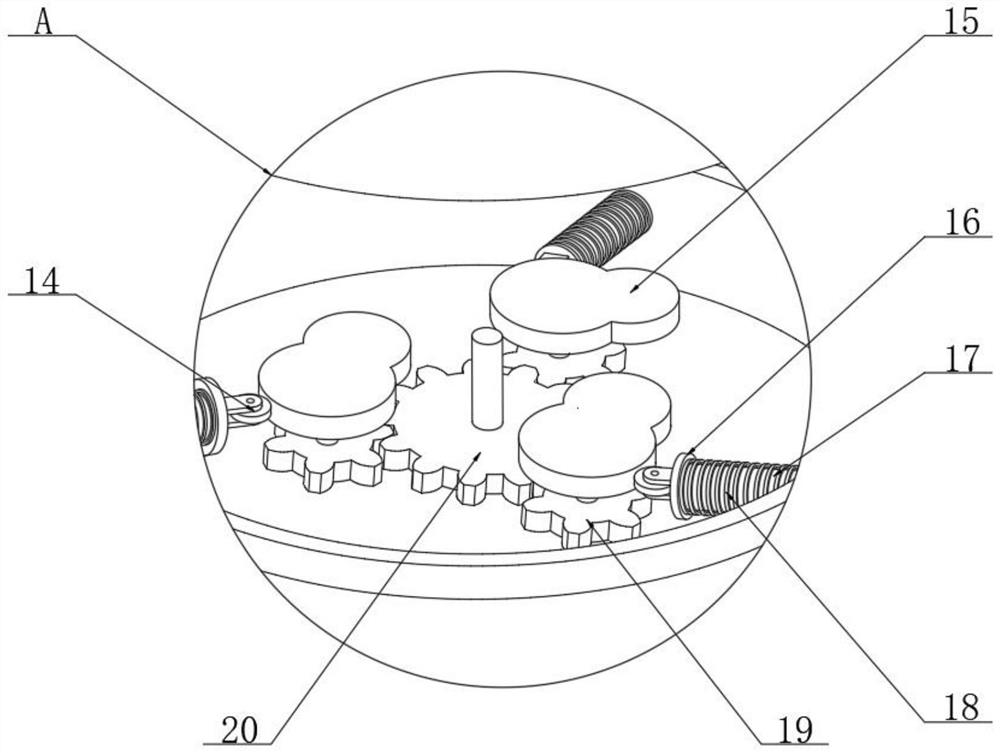

[0020] see Figure 1~5 , in an embodiment of the present invention, a processing and mixing equipment for fermenting and purifying high dietary fiber feed, comprising a base 1, a mixing drum 9 is arranged above the base 1, and a feeding port 6 is communicated above the mixing drum 9, and the stirring The top of the cylinder 9 is located on both sides of the feed port 6, and there are water inlet pipes 8 arranged symmetrically. One end of the two water inlet pipes 8 runs through the mixing drum 9 and is connected with an atomizing nozzle. In the mixing drum 9, at the same time, during the stirring process, the fermented liquid or water can be passed through the water inlet pipe 8, and sprayed evenly on the surface of the mixed and stirred raw materials through the atomizing nozzle; the upper end of the base 1 is provided with a The fermenter 32 can ensure that the materials can be fermented in the fermenter before or after mixing, which is more convenient to use.

[0021] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com