Low-concentration village and town sewage treatment method

A sewage treatment method and treatment method technology, applied in water/sludge/sewage treatment, multi-stage water treatment, water treatment parameter control, etc., can solve the problems of complex reactor structure, high operating cost, and affecting effluent water quality, etc. Achieve the effect of simple structure, low investment and operating costs, and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

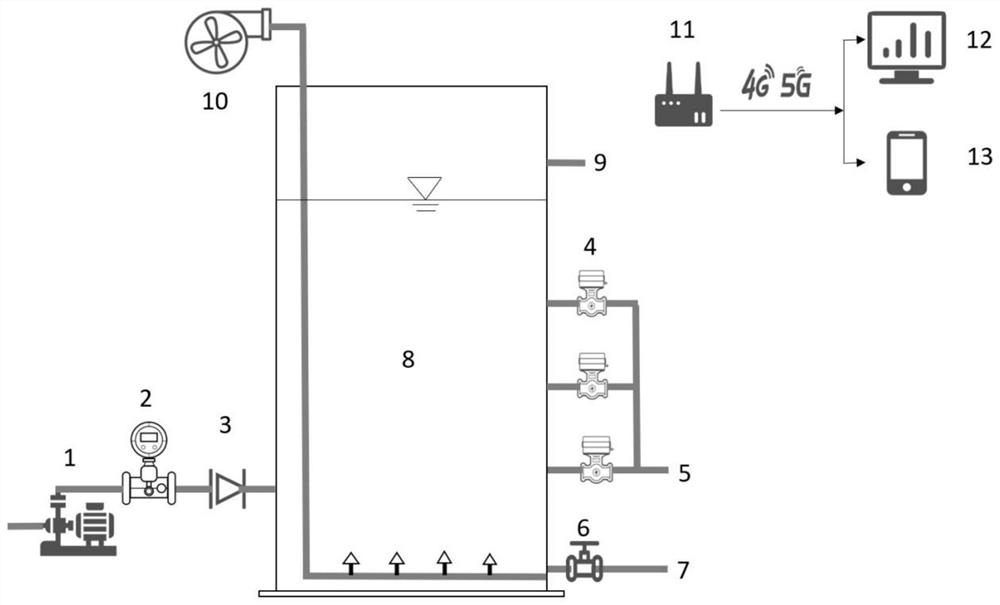

[0041] use figure 1 The device shown is for treating low-concentration village and town sewage, in which the diameter of the columnar reactor is 0.25m, the height is 1m, the effective water depth is 0.75m, and the effective height-to-diameter ratio is 3:1; water is fed from the bottom of the columnar reactor, The operation period is 4 hours, adopting the sequential batch operation mode of water intake-pulse aeration stirring-anaerobic-aerobic-stationary-pulse aeration stirring-stationary-pulse aeration stirring-sedimentation-drainage, water intake 10min, air The fan enters the columnar reactor through the aeration plate at the bottom of the columnar reactor, performs pulse aeration and stirring for 1min, anaerobic for 15min, aerobic for 142-157min, standing for 15min, pulse aeration for 1min, standing for 15min, pulse aeration Stir with air for 1 minute, settle for 15-30 minutes, and drain for 10 minutes; the aeration intensity is 0.13 cm / s; the inoculum sludge is flocculent s...

Embodiment 2

[0043] use figure 1 The device shown is for treating low-concentration village and town sewage, in which the diameter of the columnar reactor is 0.25m, the height is 1m, the effective water depth is 0.75m, and the effective height-to-diameter ratio is 3:1; water is fed from the bottom of the columnar reactor, The operation period is 3 hours, and the sequential batch operation mode of water intake-pulse aeration stirring-anaerobic-aerobic-standstill-pulse aeration stirring-sedimentation-drainage is adopted; half a month before the operation, when the water exchange ratio is less than 50%, The sequence batch operation mode is as follows: water is fed for 10 minutes, air enters the columnar reactor from the fan through the aeration plate at the bottom of the columnar reactor, pulse aeration is performed for 1min, anaerobic for 19min, aerobic for 90-100min, standing for 19min, Pulse aeration and stirring for 1 minute, sedimentation for 25-30 minutes, drainage for 10 minutes; when ...

Embodiment 3

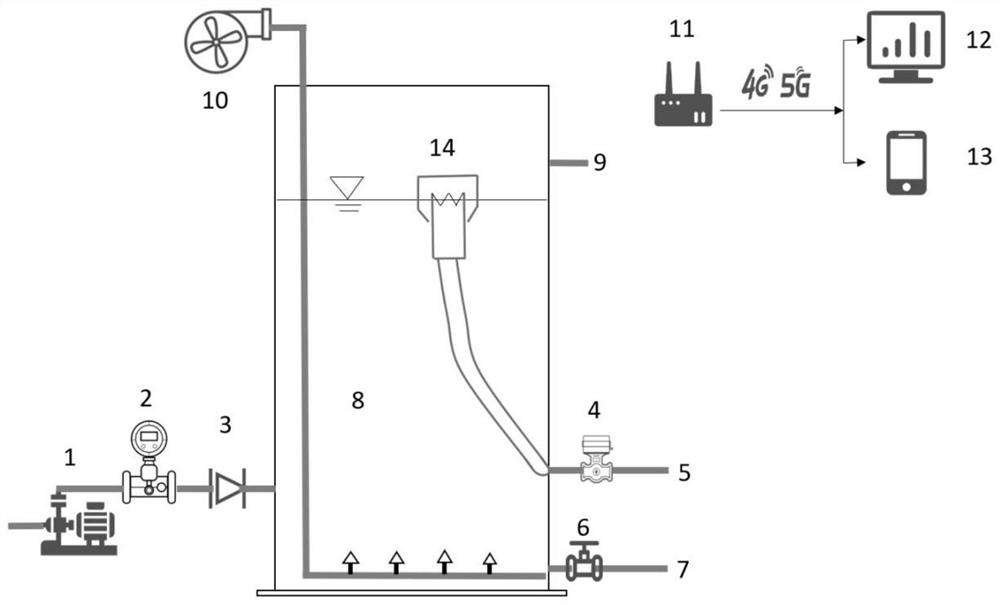

[0045] use figure 2 The device shown treats low-concentration village and town sewage, in which the columnar reactor has a diameter of 4m, a height of 4.5m, an effective water depth of 4m, and an effective height-to-diameter ratio of 1:1; The period is 3 hours, using the sequential batch operation mode of water intake-pulse aeration stirring-anaerobic-aerobic-standstill-pulse aeration stirring-sedimentation-drainage, water intake 15min, air is passed through the bottom of the column reactor by the fan The aeration tray enters the columnar reactor, performs pulse aeration and stirring for 1min, anaerobic for 15min, aerobic for 92-102min, standing for 15min, pulse aeration for 2min, sedimentation for 20-30min, and drainage for 10min; the aeration intensity is 0.17cm / s; The inoculum sludge is flocculent sludge from the aerobic tank of a sewage treatment plant, and the inoculum volume is 5g MLSS / L. Due to the relatively low height and diameter, decanting equipment is used for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com