Tubular photo-biological reactor CO2 refining device

A photobioreactor and tube-type technology, applied in the direction of photobioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the problem of inability to guarantee microalgae photosynthesis, pump installation Difficult to achieve precision, poor bubble refinement effect, etc., to achieve the effect of gas-liquid two-phase mass transfer and sufficient mixing, good refinement effect, and long residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

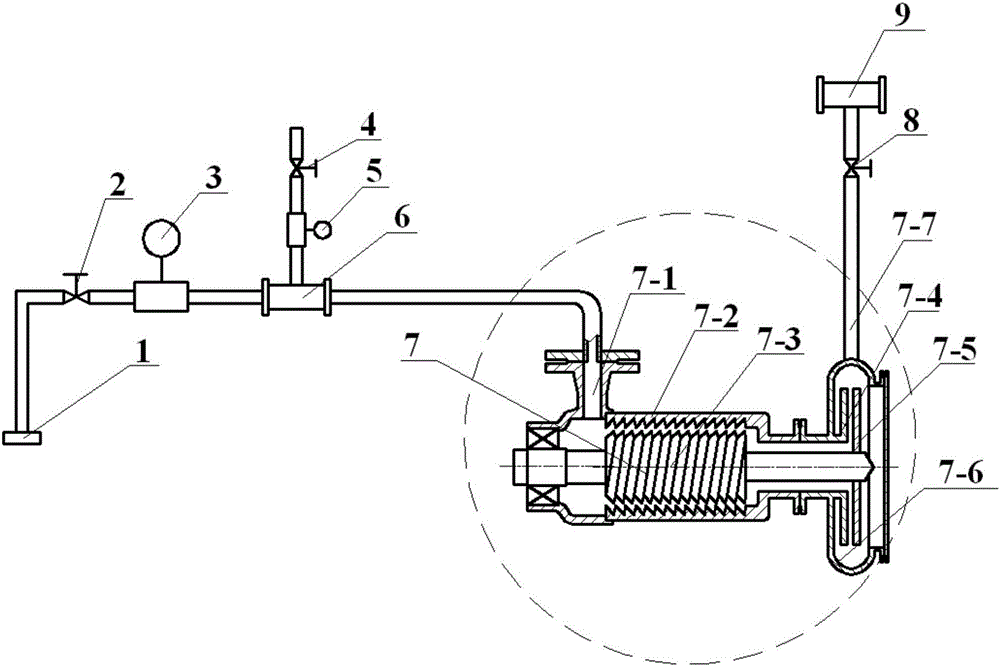

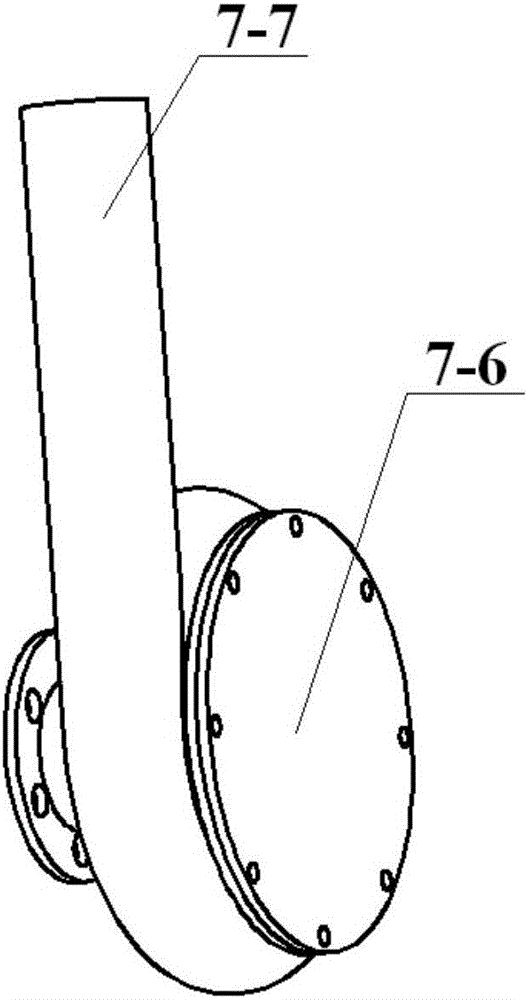

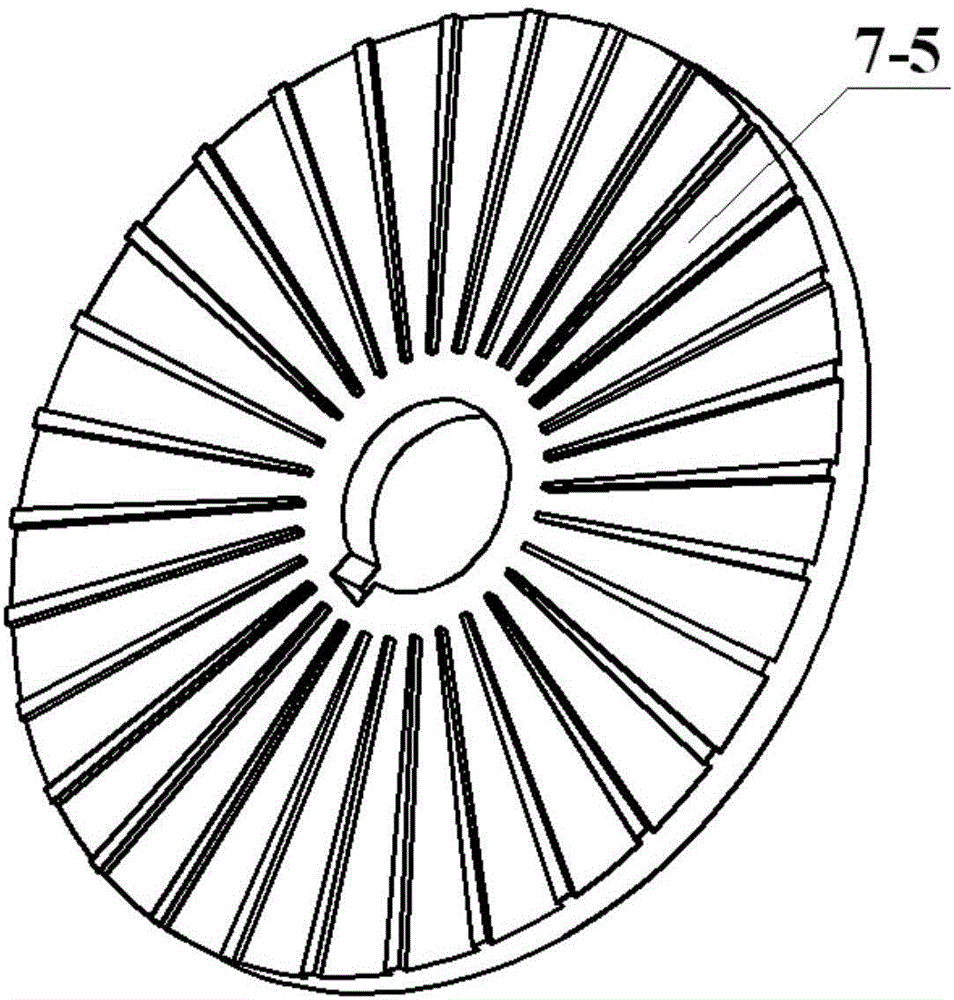

[0025] Such as figure 1 Shown, a kind of tubular photobioreactor CO of the present invention 2 The refining device includes filtering device 1, liquid valve 2, liquid flow meter 3, gas valve 4, gas flow meter 5, gas-liquid mixing tee 6, axial flow and runoff composite labyrinth screw pump 7, microbubble liquid valve 8 and micro The bubble liquid tee 9, wherein the axial flow and radial flow compound labyrinth screw pump 7 includes a pump inlet 7-1, a stator 7-2, a rotor 7-3, a fixed disk 7-4, a thinning disk 7-5, and a volute 7- 6 and pump outlets 7-7.

[0026] Such as Figure 5 Shown, a kind of tubular photobioreactor CO of the present invention 2 The refining device is applied to a tubular photobioreactor, including a water tank 10 , a process pump 11 , an algae solution valve 12 , and a photoreaction pipeline 13 .

[0027] When working, the filter device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com