Method for treating nickel-cobalt alloy waste

A nickel-cobalt alloy and waste technology, which is applied in the field of direct treatment of nickel-cobalt alloy waste by swirl electrolytic leaching, can solve the problems of not using swirl electrolysis, etc., and achieve the effects of improving metal recovery rate, fully utilizing resources, and efficient treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

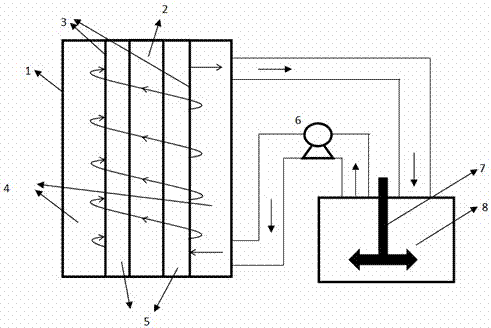

Image

Examples

Embodiment 1

[0025] The experimental raw material in this example is nickel-based alloy scrap, the main chemical composition (%): Ni 63.61, Co 8.53, W7.11, Mo 5.10, Al 1.15, Cr 2.21, Ta 6.38, Nb 0.50. Has a high recycling value.

[0026] The method for processing nickel-cobalt alloy waste of the present embodiment may further comprise the steps:

[0027] (1) Grinding the nickel-cobalt alloy waste material and passing it through a 200-mesh sieve; mixing evenly the dilute sulfuric acid solution and the nickel-cobalt alloy waste material according to the liquid-solid volume mass ratio of 8 ml:1g to obtain a slurry;

[0028] Described dilute sulfuric acid concentration is 200g / L;

[0029] (2) Put the slurry in the slurry tank, and the slurry enters the swirl electrolysis system through the pneumatic pump (the feeding speed of the slurry is 0.3L / min) for swirl electrolysis. The conditions for swirl electrolysis are: temperature 75°C, the cathode current density is 150A / m 2 . After electroly...

Embodiment 2

[0032] The experimental raw material in this example is nickel-based alloy scrap, the main chemical composition (%): Ni 63.61, Co 8.53, W7.11, Mo 5.10, Al 1.15, Cr 2.21, Ta 6.38, Nb 0.50. Has a high recycling value.

[0033] The swirl electrolytic leaching method of the present embodiment directly processes the nickel-cobalt alloy fertilizer, comprising the following steps:

[0034] (1) Grind the nickel-cobalt alloy waste material and pass it through a 200-mesh sieve; mix the dilute sulfuric acid solution and the nickel-cobalt alloy waste material according to the liquid-solid volume mass ratio of 10 ml:1g to obtain a slurry;

[0035] Described dilute sulfuric acid concentration is 180g / L;

[0036] (2) Put the slurry in the slurry tank, and the slurry enters the swirl electrolysis system through a pneumatic pump (the feeding speed of the slurry is 0.5L / min) for swirl electrolysis. The conditions for swirl electrolysis are: temperature 85°C, the cathode current density is 160...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com