Anhydrous hydrogen fluoride preparation process

An anhydrous hydrogen fluoride and process technology, which is applied in the field of anhydrous hydrogen fluoride preparation process, can solve the problems of shortening the maintenance period of the device, reducing the heat transfer efficiency of the rotary furnace, and scaling on the inner wall of the rotary reaction furnace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

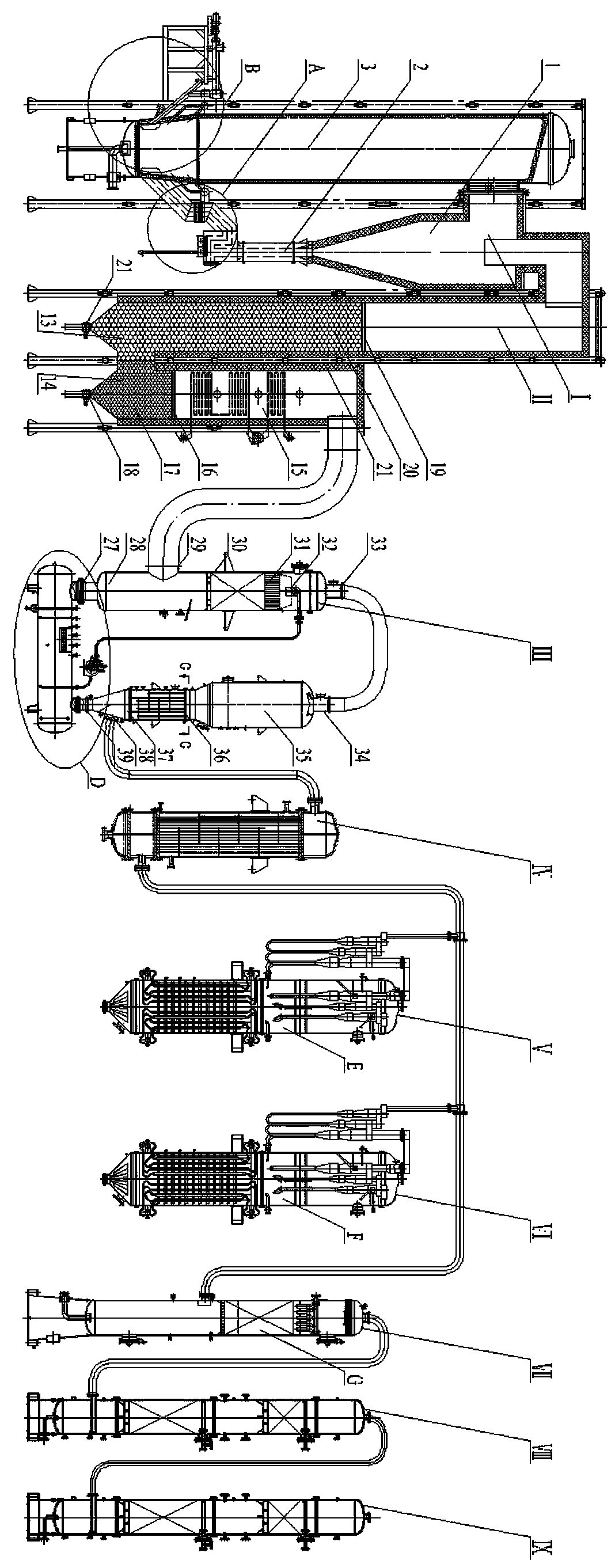

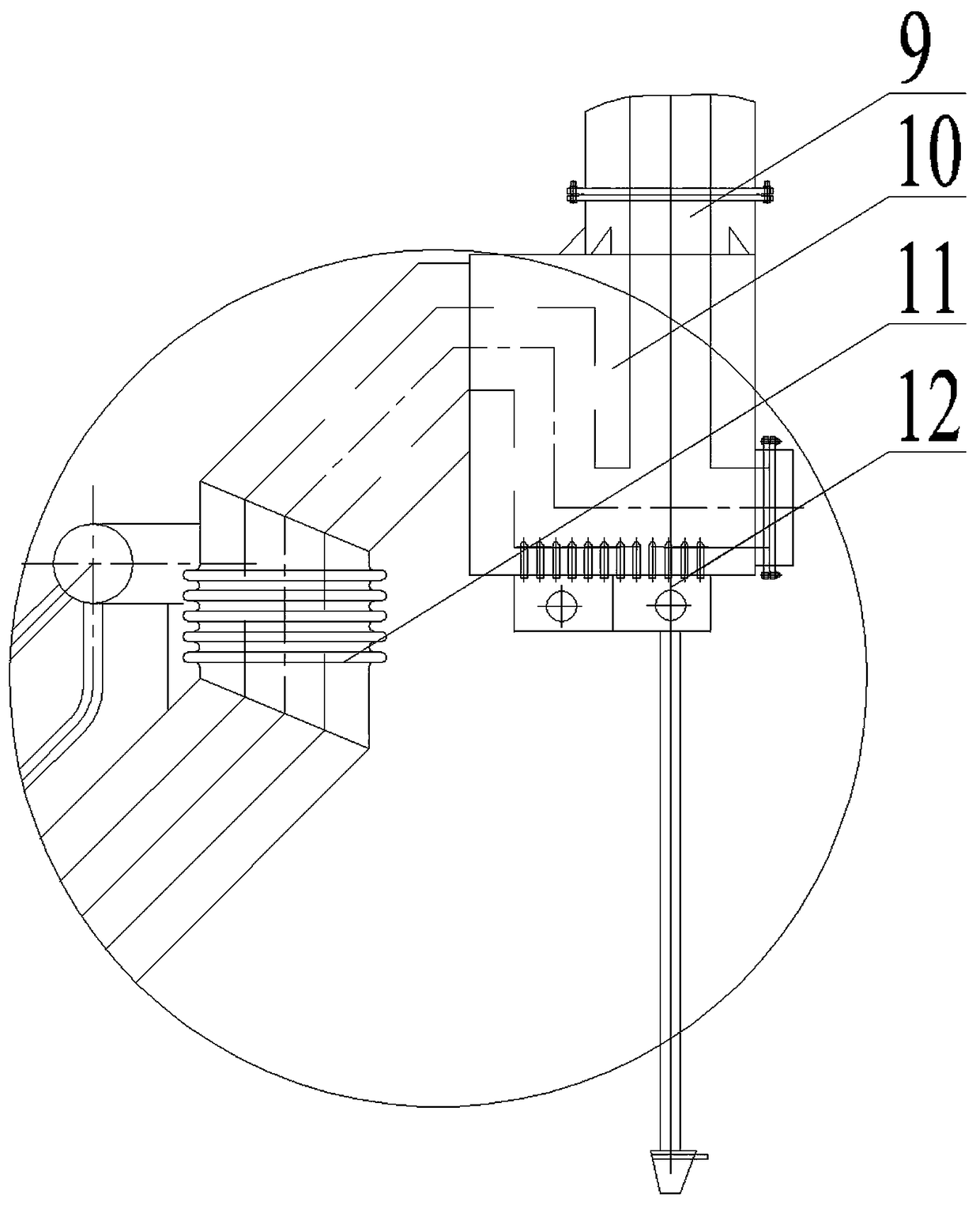

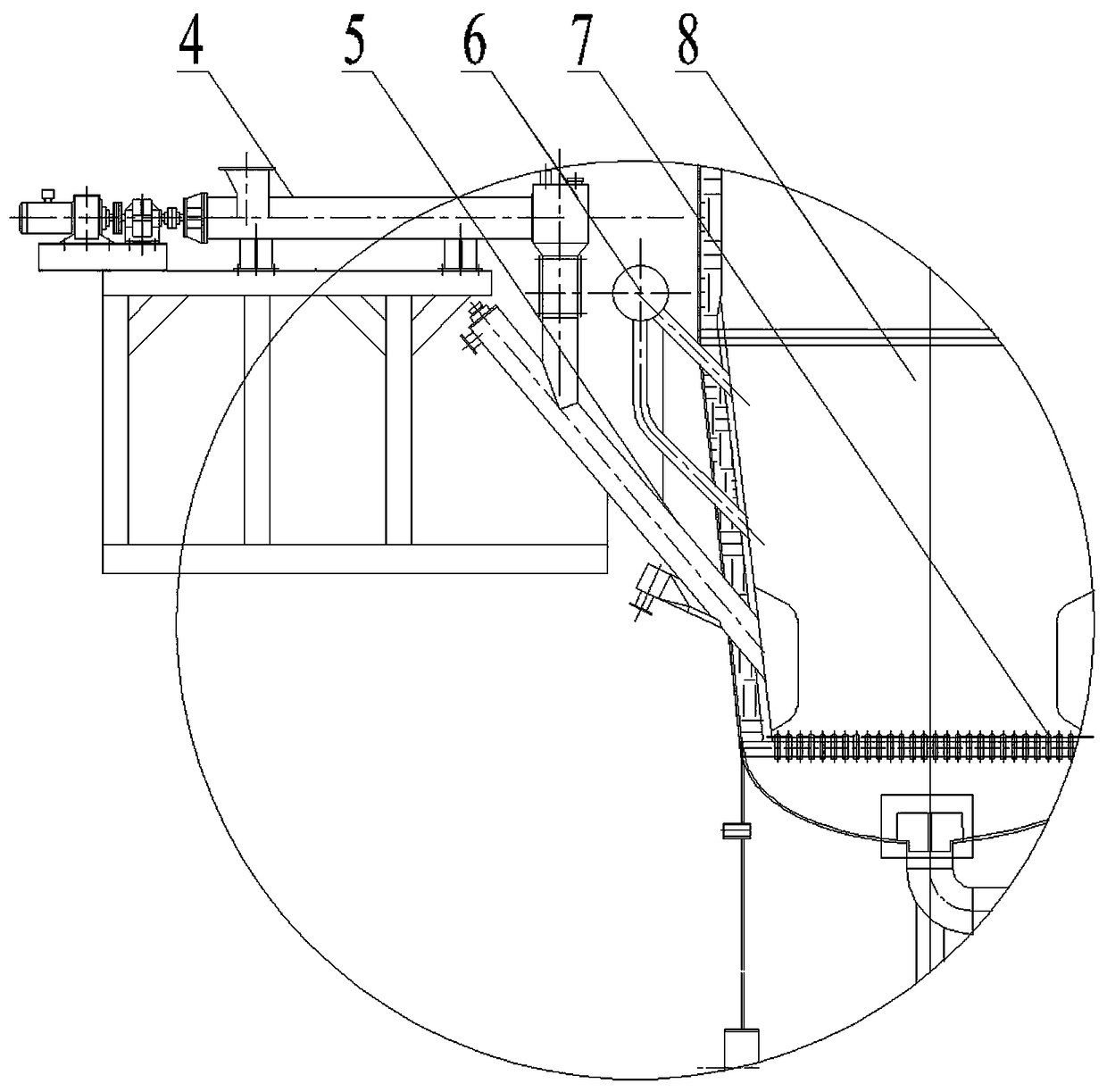

[0047] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 Shown, a kind of anhydrous hydrogen fluoride preparation process is characterized in that:

[0048] It includes circulating fluidized bed reaction process, granular layer moving bed filtration process, washing and condensation process, circulating fluidized bed rectification process, circulating fluidized bed degassing process, and tail gas environmental protection treatment process.

[0049] Process 1, circulating fluidized bed reaction process, fluorite is crushed into 3~5mm and sieved, the sulfuric acid recovered from the packed absorption tower VII and circulating fluidized bed rectification tower Ⅴ is mixed according to the mass ratio of 1:1.2~1.3 for later use, and the heat medium And the conveying medium is 300~450℃, 0.1MPa s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com