Multifunctional composite type centrifugal vibration adverse-flow solid dryer and method

A composite and multi-functional technology, applied in dryers, drying solid materials, drying goods processing, etc., can solve the problems of unstable temperature, affecting drying effect, low thermal efficiency, etc., to improve drying efficiency, increase drying effect, High thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] For ease of understanding, the present invention will be further explained in detail below in conjunction with the accompanying drawings.

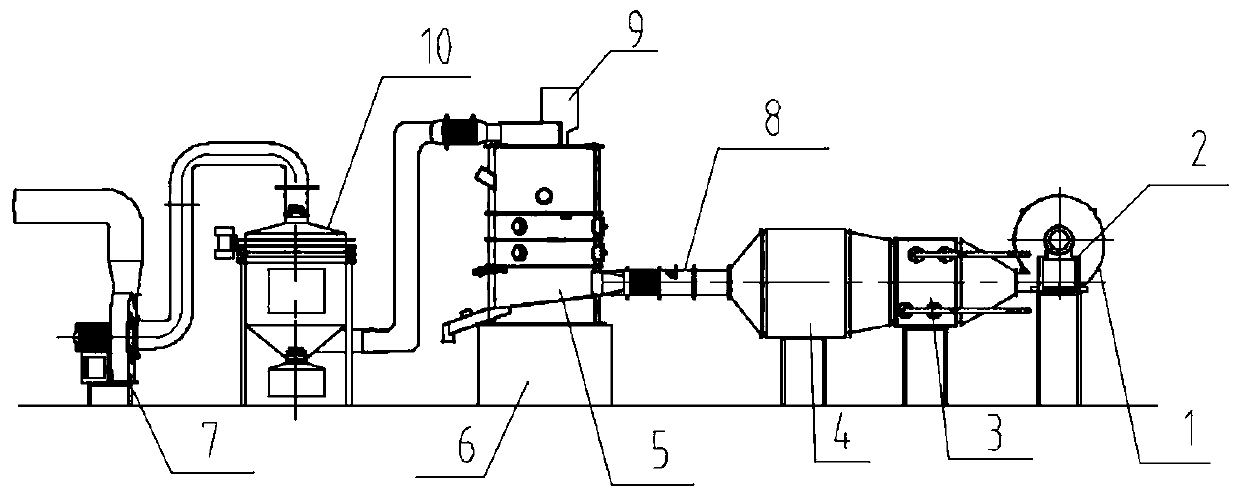

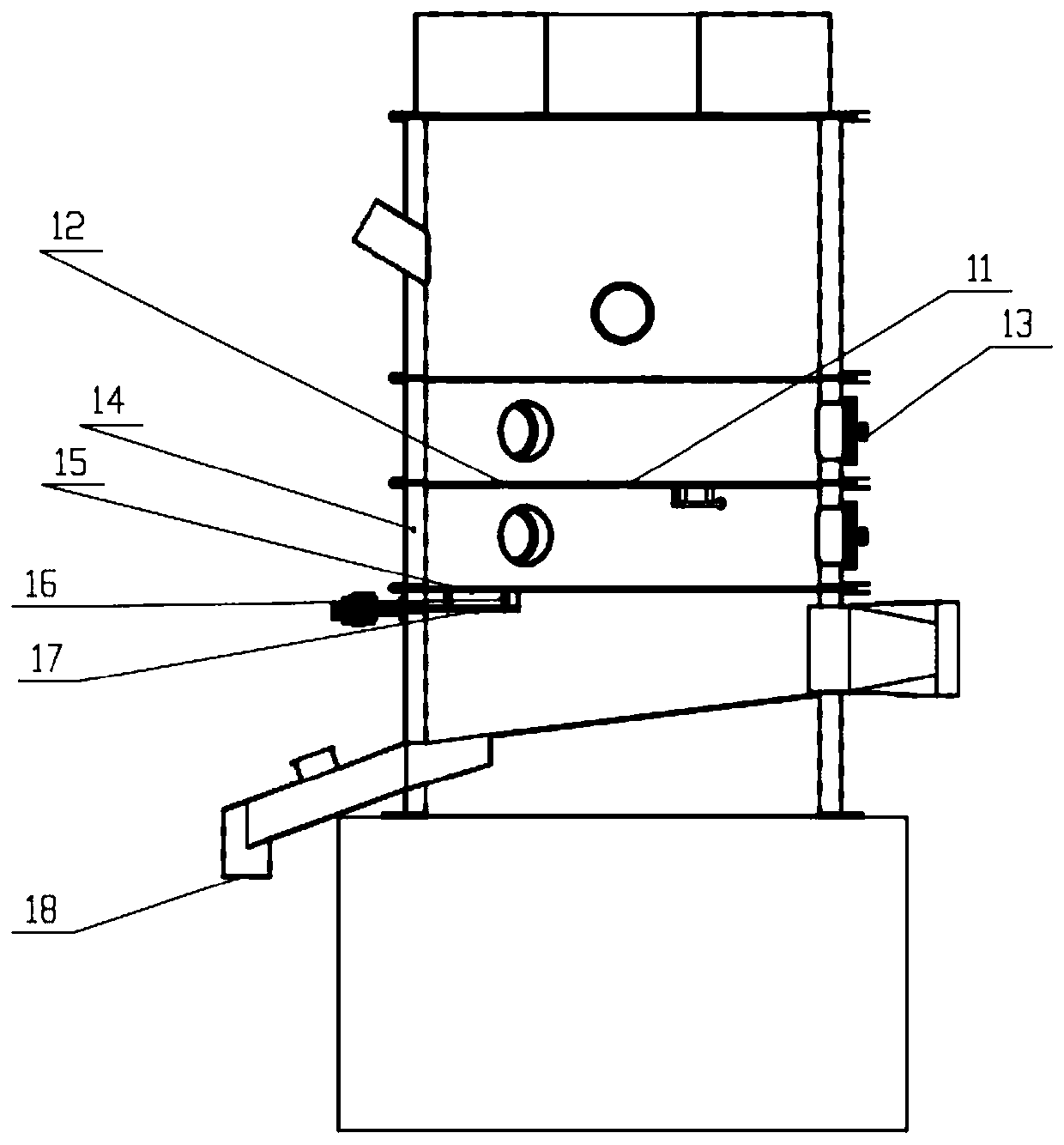

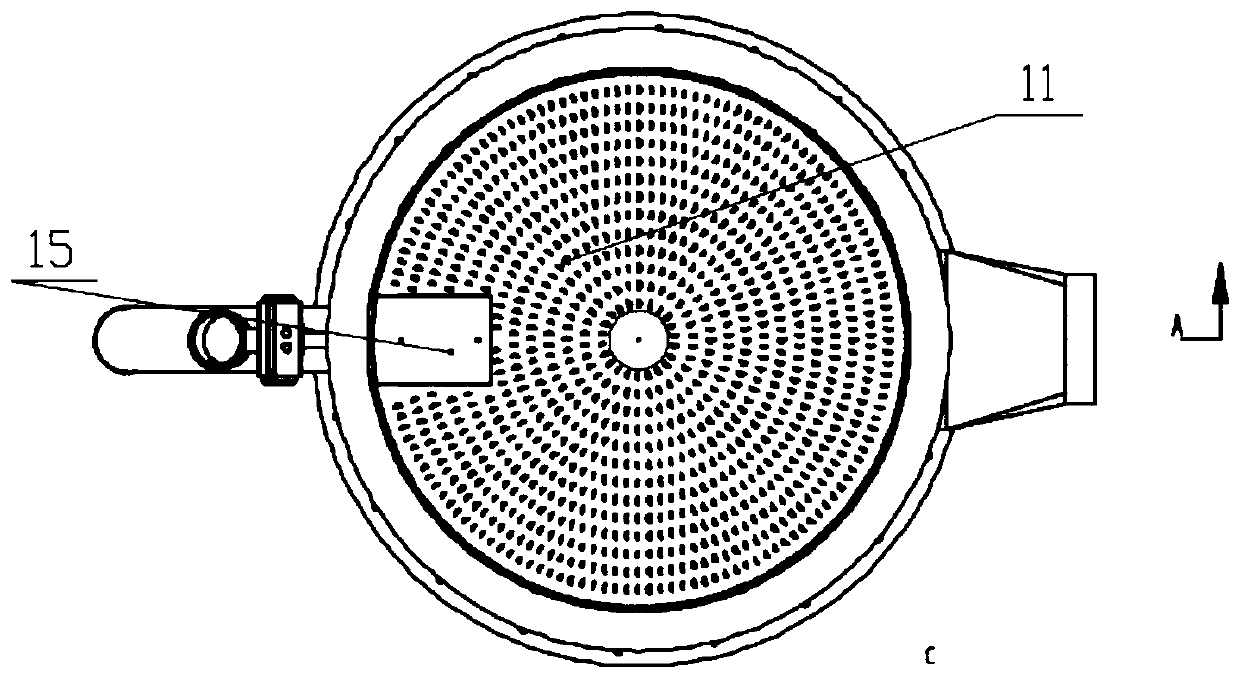

[0024] Such as figure 1 As shown, a multi-functional composite spiral vibration countercurrent solid dryer includes an air filter 1, a blower 2, a heat exchanger 3, a high-efficiency filter 4, an air valve 8, a vibration platform 6, a drying tower 5, and a negative pressure upper Feeder 9, dust collector 10, induced draft fan 7 and PLC controller, air filter 1 is installed at the air inlet of blower 2, the air outlet of blower 2 is connected to the air inlet of heat exchanger 3, and the air outlet of heat exchanger 3 is connected to high-efficiency The air inlet of the filter 4, the air outlet of the high efficiency filter 4 are connected to the air inlet at the bottom of the drying tower 5, the air outlet at the top of the drying tower 5 is connected to the air inlet of the dust collector 10 through a pipeline, and the air outlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com