Gas-liquid contact type residual heat recovery device

A waste heat recovery, gas-liquid contact technology, applied in direct contact heat exchangers, heat exchanger types, water shower coolers, etc. Unfavorable recycling and utilization problems, to achieve the effect of light weight, simple structure, and sufficient mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

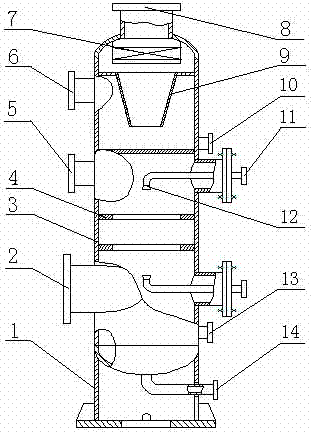

[0018] Such as figure 1 It can be seen from the schematic diagram of the front view of the structure of the present invention that the gas-liquid contact waste heat recovery device consists of a skirt 1, a gas inlet pipe 2, a shell 3, an annular liquid blocking plate 4, a gas screw-out tube 5, and a gas screw-in Pipe 6, demister 7, gas outlet pipe 8, gas distribution cone 9, liquid return outlet pipe 10, cold liquid inlet pipe 11, nozzle 12, liquid return inlet pipe 13, hot liquid outlet pipe 14, in which the shell 3 The lower part has a gas inlet pipe 2, which is connected to the gas input pipe; multiple nozzles 12 are installed in the housing 3, and the nozzles 12 are connected to the cold liquid inlet pipe 11, and connected to the cold liquid delivery pipe; The liquid plate 4 intercepts the liquid on the wall of the shell 3 and returns it to the gas rising space;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com