Novel method for terminating allyl alcohol irregular polyether methyl

A random polyether, methyl-terminated technology, applied in ether preparation, ester reaction to ether, organic chemistry, etc., can solve the problems of complex post-treatment process, difficult mass transfer, deep color of the product, etc., and achieve uniform concentration distribution Improve and promote the mass transfer process and ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

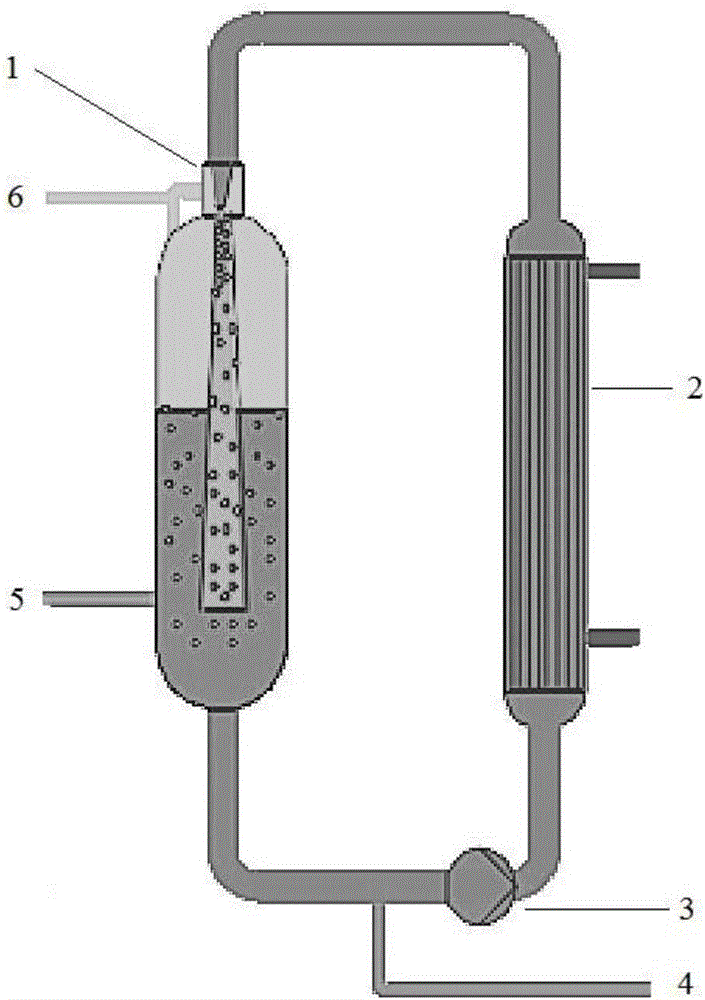

[0035] (1) In the jet loop reactor based on the Venturi effect, (the operating principle is based on the Venturi effect, the loop operation is downward flow, and the end of the jet mixer 1 of the reactor is immersed in the liquid phase of the loop reactor Middle), add 400kg of allyl alcohol random polyether raw material (molecular weight: 400), deoxygenate and nitrogen replacement protection, turn on the external circulation pump 3 for high-speed jet mixing.

[0036] (2) Control the temperature at 20°C, slowly feed 51kg of monochloromethane raw material and 135kg of liquid caustic soda (30%NaOH solution) into the injection loop reactor, spray and mix and realize the full reaction of the three, and the feeding time for 24 hours. After the addition was complete, the reaction was terminated after continuing the reaction in the jet loop reactor for 8 hours.

[0037] (3) After the reaction, the obtained crude product is neutralized with 50% phosphoric acid, and then undergoes a po...

Embodiment 2

[0039] (1) In the jet loop reactor based on the Venturi effect, (the operating principle is based on the Venturi effect, the loop operation is downward flow, and the end of the jet mixer 1 of the reactor is immersed in the liquid phase of the loop reactor Middle), add 600kg of allyl alcohol random polyether raw material (molecular weight: 6000), deoxygenate and nitrogen replacement protection, turn on the external circulation pump 3 for high-speed jet mixing.

[0040] (2) Control the temperature at 70°C, slowly feed 10.1kg of monochloromethane raw material and 11.3kg of solid potassium hydroxide particles into the injection loop reactor, spray and mix to realize the full reaction of the three, and the feeding time is 4 Hour. After the addition was complete, the reaction was terminated after continuing the reaction in the jet loop reactor for 1 hour.

[0041] (3) After the reaction, the obtained crude product is neutralized with 50% phosphoric acid, and then undergoes a post-t...

Embodiment 3

[0043] (1) In the jet loop reactor based on the Venturi effect, (the operating principle is based on the Venturi effect, the loop operation is downward flow, and the end of the jet mixer 1 of the reactor is immersed in the liquid phase of the loop reactor Middle), add 512.5kg of allyl alcohol random polyether raw material (molecular weight: 1025), deoxygenate and nitrogen replacement protection, open the external circulation pump 3 for high-speed jet mixing.

[0044] (2) Control the temperature at 30°C, slowly feed 32.8 kg of monochloromethane raw materials and 15.6 kg of solid sodium hydride particles into the injection loop reactor, spray and mix to achieve a full reaction of the three, and the feeding time is 12 Hour. After the addition was complete, the reaction was terminated after continuing the reaction in the jet loop reactor for 4 hours.

[0045] (3) After the reaction, the obtained crude product is neutralized with 50% phosphoric acid, and then undergoes a post-trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color | aaaaa | aaaaa |

| color | aaaaa | aaaaa |

| color | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com