Reactor for producing biodiesel in presence of solid catalyst

A solid catalyst, biodiesel technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve problems such as reducing equipment utilization, affecting conversion rate, insufficient contact between reaction substrate and catalyst, and extending service life. , the effect of convenient reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

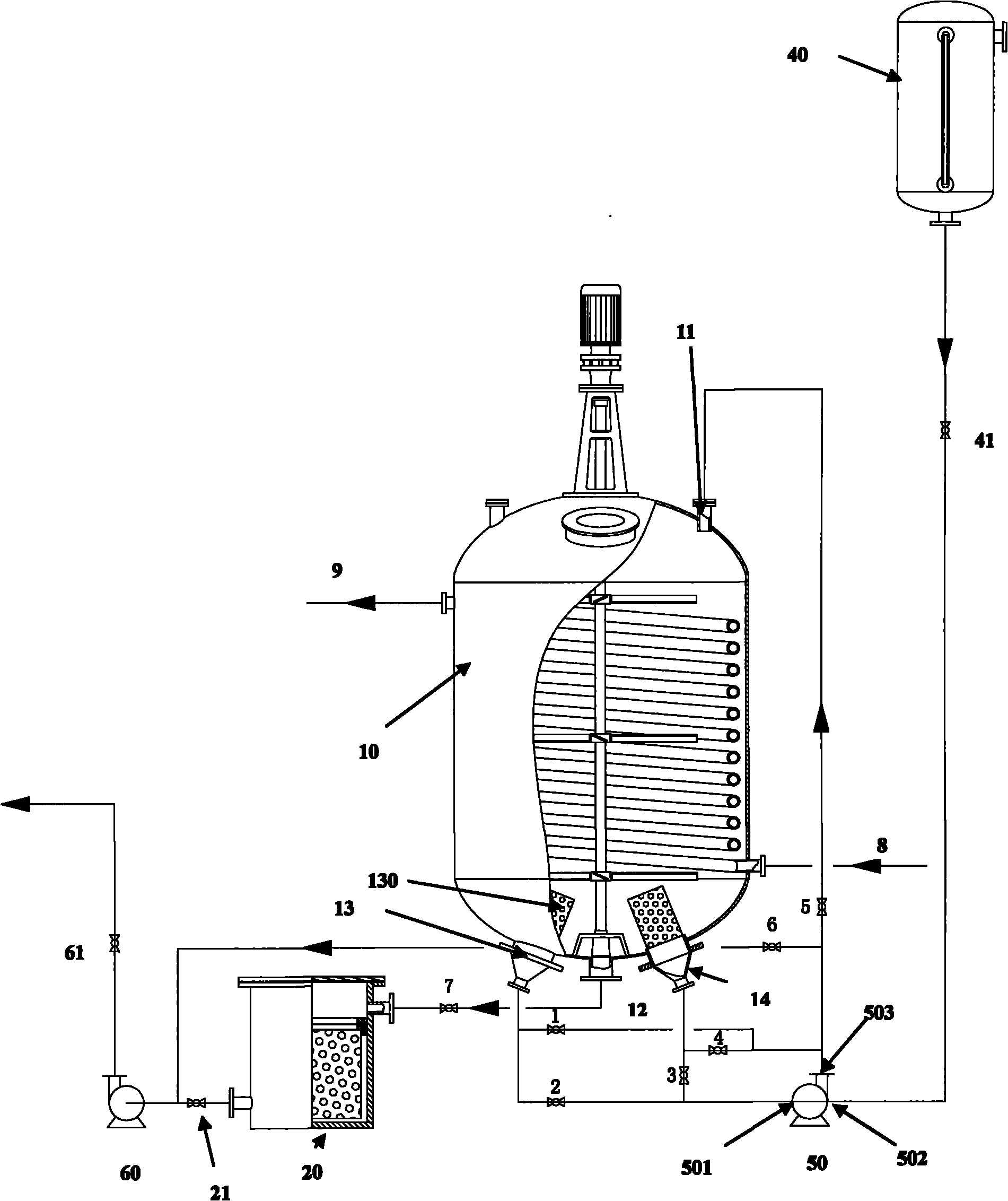

[0019] Such as figure 1 As shown, it is a reactor for the production of biodiesel catalyzed by a solid catalyst. The reactor is a stirred tank reactor 10. In the stirred tank reactor 10, there are two built-in filters that open downward and extend out of the tank. Devices 13 and 14, each built-in filter is provided with a layer of filter screen, and the mesh of the filter screen is smaller than the particle size of the solid catalyst particle for reaction, which can stop the catalyst from leaking from the built-in filter 13 and the filter 14. The circulation pump in this embodiment is a centrifugal mixing pump 50 which has an inlet 501 , an inlet 502 and a total outlet 503 . The built-in filter 13 communicates with the pipeline 2 and the recoil pipeline 1; the built-in filter 14 communicates with the pipeline 3 and the recoil pipeline 4; And recoil pipeline 4 is communicated with the total outlet 503 of centrifugal mixing pump 50; Feed port 11 is communicated with the total o...

Embodiment 2

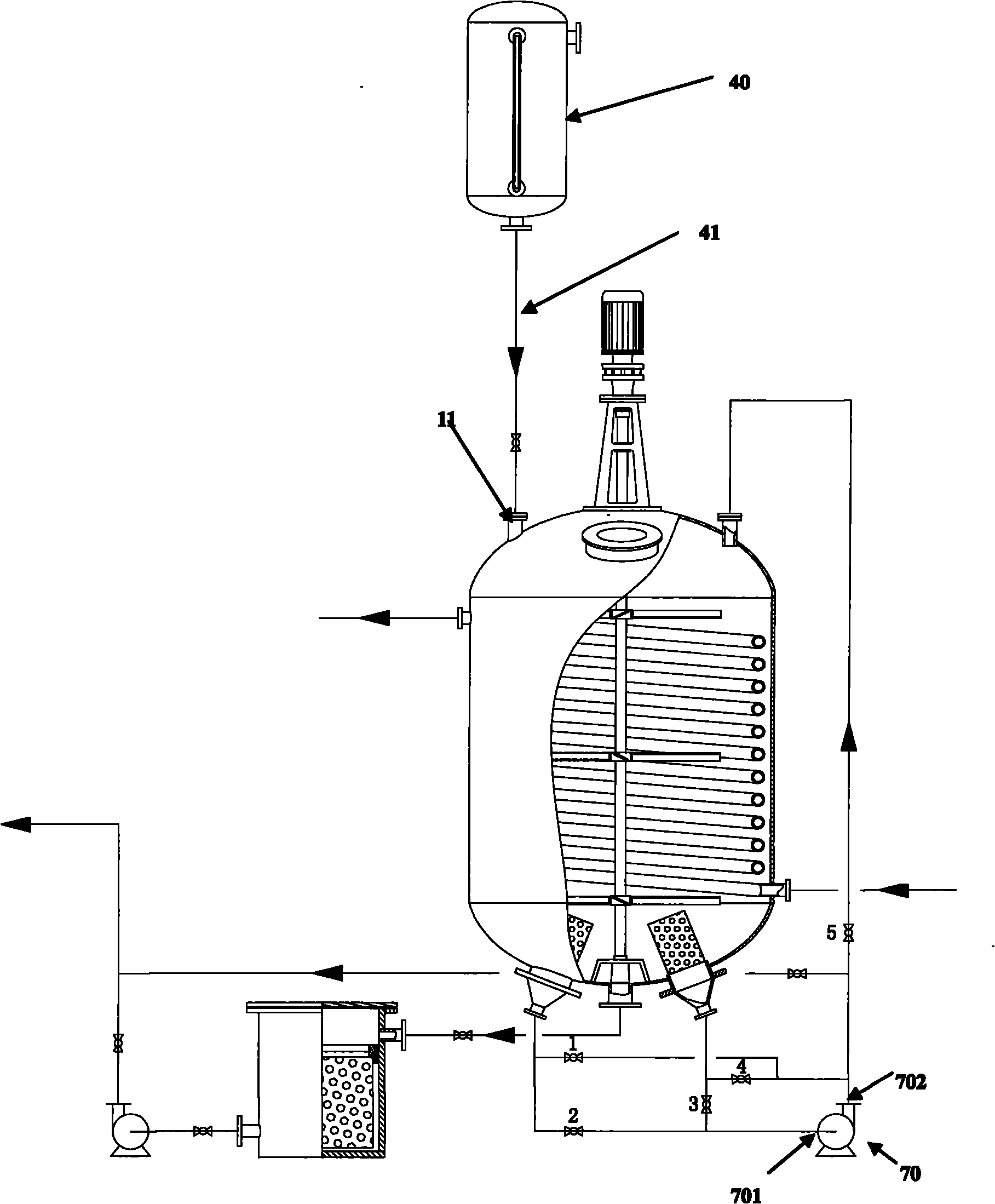

[0023] Another embodiment of the present invention is formed after the above-mentioned equipment is changed, such as figure 2 As mentioned above, the methanol storage tank 40 can be directly communicated with another feed port 11 of the stirred tank reactor 10 through the pipeline 41. At this time, the circulation pump is a common pump 70, and the inlet 701 of the pump 70 is connected to the pipeline 2 of the outlet of the filter. The pipeline 3 is connected; the outlet 702 of the pump 70 is connected with the recoil pipeline 1 of the filter, the backflush pipeline 4, and the pipeline 5, and the pipeline 5 is connected with the feed port of the stirred tank.

[0024] Similarly, use figure 2 The equipment shown produces biodiesel that differs from figure 1 The first step is to directly add the methanol in the methanol storage tank 40 to the stirred tank reactor 10 without transporting it through an external circulation pump. the rest with figure 1 The steps for using the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com