Air-lifting type external-circulation vortex enhanced biological nitrogen-removal reactor

A biological denitrification and external circulation technology, applied in the direction of aerobic and anaerobic treatment, can solve the problems of full mixed flow and low efficiency, reduce mass transfer resistance, ensure environmental sanitation, improve denitrification efficiency and volumetric efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

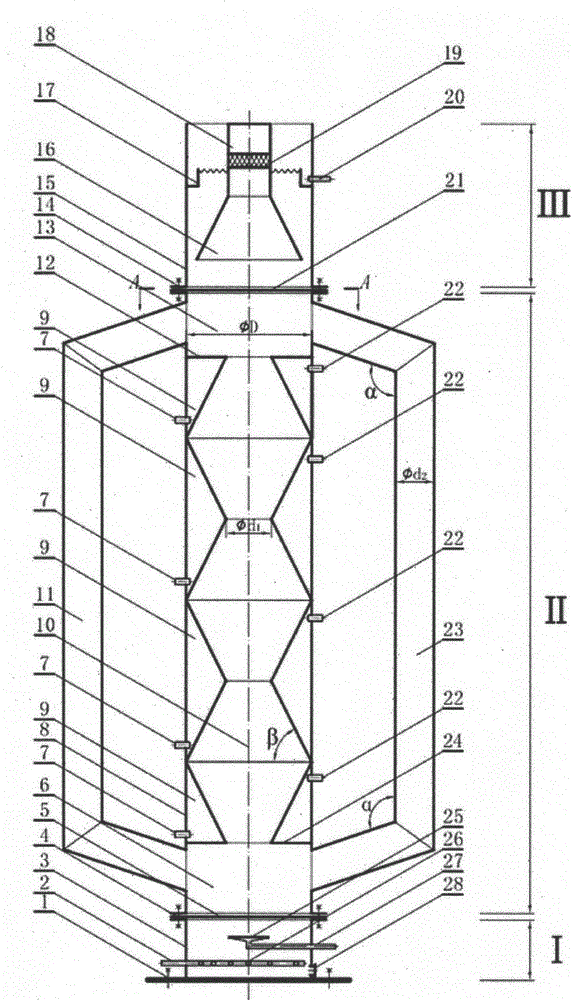

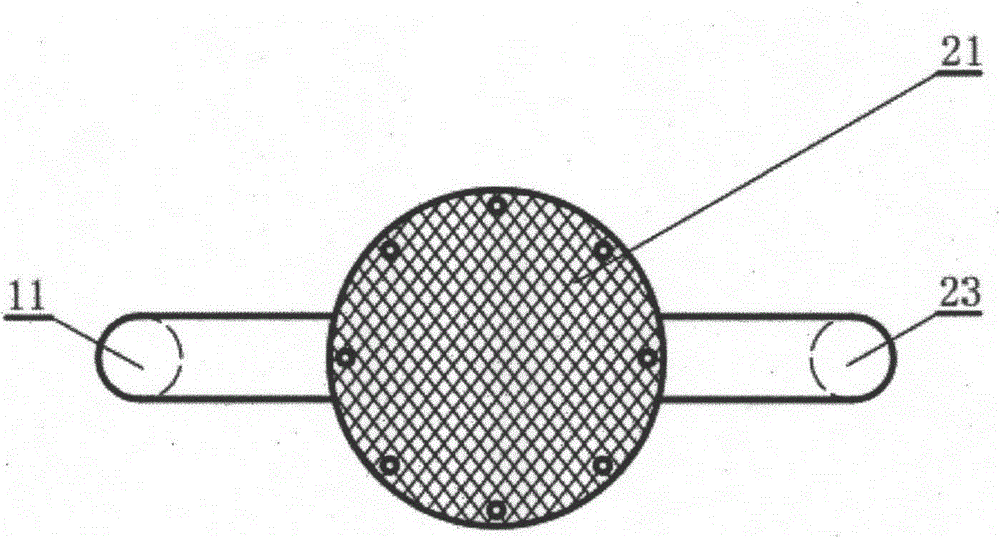

[0034] Such as Figure 1-2 As shown, it is a schematic structural diagram of the air-lift external circulation vortex-enhanced biological denitrification reactor provided by the present invention, including water distribution section I, reaction section II and separation section III from bottom to top, and the water distribution section I includes The lower short cylinder 3 arranged on the bottom plate 1, the lowest part of the outer side of the lower short cylinder 3 is provided with an emptying port 28, and the lower short cylinder 3 is provided with a water distributor 26, a microporous aeration plate 25, and a water distributor 26 communicates with the water inlet pipe 2 located at the outer side of the lower short cylinder 3 , and the microporous aeration disc 25 communicates with the air intake pipe 27 installed at the outer side of the lower short cylinder 3 . The microporous aeration pan 25 and the air inlet pipe 27 are set on the same level, the water inlet pipe 2 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com