First-division up-flow combined baffle plate anaerobic hydrolysis reaction integrated device

A baffle plate anaerobic and hydrolysis reaction technology, applied in the field of sewage treatment equipment, can solve the problems of poor impact load resistance, poor treatment effect, sludge loss, etc., achieve strong impact load resistance, reduce anaerobic pollution Effect of mud loss and improvement of mud-water mixing state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

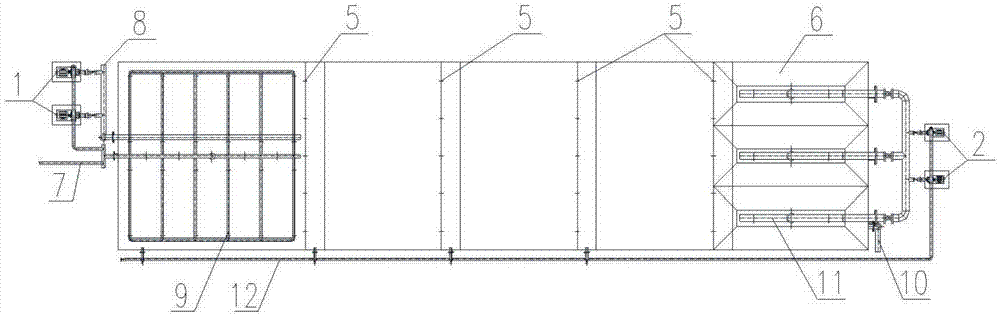

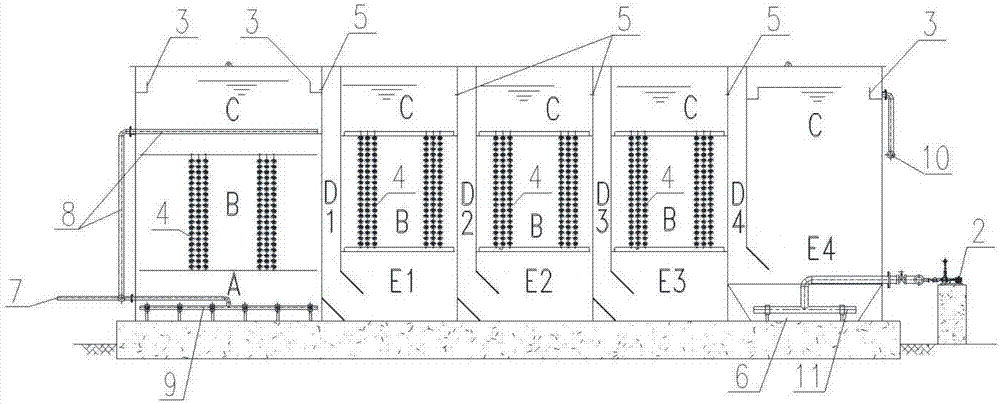

[0032] Such as Figure 1~2 The Shouge up-flow combined baffle anaerobic hydrolysis reactor shown in the figure is a steel structure with a treatment capacity of 200m 3 / d, the treatment object is high-concentration wastewater from a chemical enterprise, the concentration of which enters the anaerobic hydrolysis reactor is COD=5000mg / L, and the concentration of phenol is ≤100mg / L.

[0033] The whole reactor is divided into five reaction chambers, which are the first single-group UASB and four-cell ABR up-and-down flow reaction chambers (single group) connected in series. Each reaction chamber is separated by a partition and relies on the flow hole to pass water. After being collected, the waste water enters the Shouge UASB from the bottom. The water inlet distribution pipe 9 is a circular perforated pipe for water distribution, and the opening is downward to prevent the sedimentation sludge from blocking the water inlet pipe 7 . During the upflow process, the sewage contacts t...

Embodiment 2

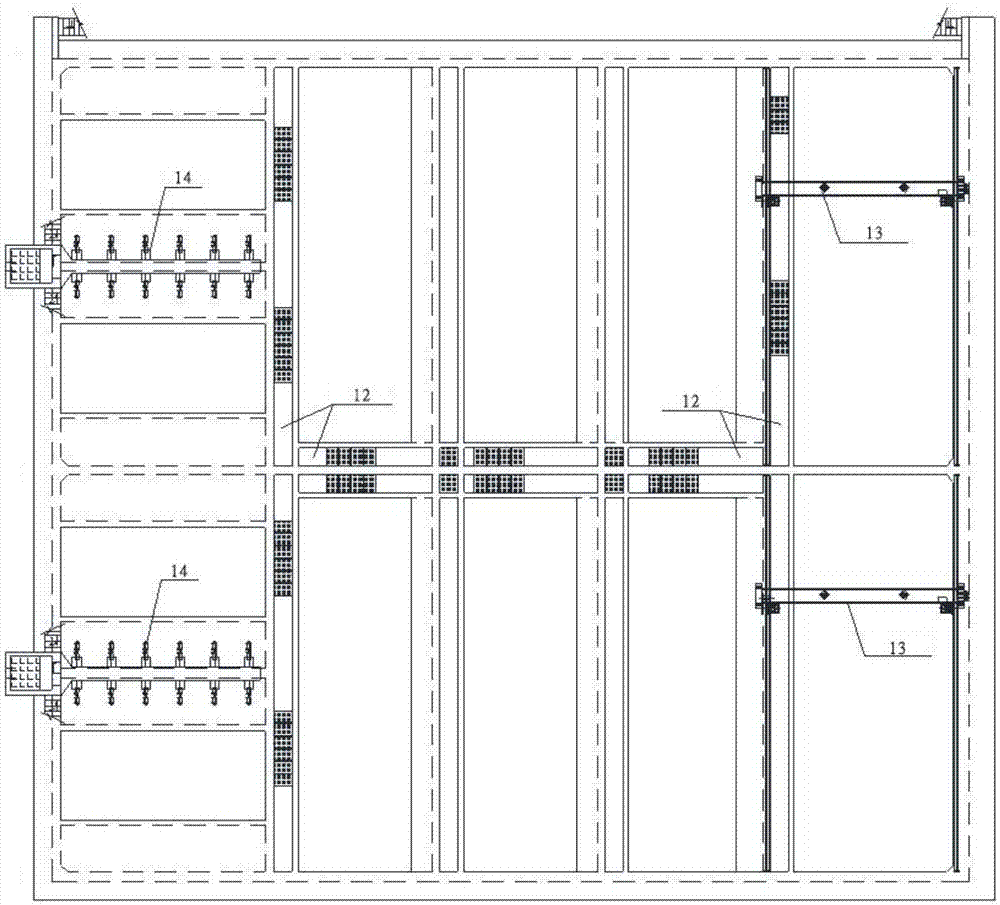

[0039] Such as image 3 The first grid up-flow combined baffle plate anaerobic hydrolysis reaction integrated device shown is a steel concrete structure, and the water treatment volume is 10000m 3 / d, the treatment object is comprehensive wastewater from a chemical industrial park, and its concentration entering the anaerobic hydrolysis reactor is COD=350-400mg / L.

[0040] The whole reactor is divided into five reaction chambers, which are the first grid UASB (four groups parallel), four ABR up and down flow reaction chambers (two groups) connected in series, each reaction chamber is separated by a partition, relying on the flow hole to pass water, Every two groups of up-flow reaction chambers correspond to a group of ABR reaction chambers. Due to the large number of pools, the collected waste water enters the first up-flow reaction chamber through the water distributor 14. Specifically, perforated pipes are used for water distribution, and the opening is downward to prevent ...

Embodiment 3

[0046] It is basically the same as in Example 1, except that the first UASB (two groups are arranged side by side), and the five ABR up and down flow reaction chambers (three groups) are connected in series, and the volume of the filler in each ABR accounts for 1 / 4 of the volume of the device. The width of the fifth grid ABR is 10% larger than that of the first four grids. The volume ratio of the ABR up and down flow reaction chamber is 3:1, the angle between the partition and the baffle is 120°, and the angle between the ABR pool wall and the baffle is 120° °; The reflux ratio of the supernatant of Shouge UASB is 3:1, and the reflux ratio of the sludge collected by the last ABR is 1:1.

[0047] The treated water volume is 4000m 3 / d, influent COD=500~600mg / L. After treatment, the effluent COD is about 300mg / L, and the removal rate is about 40-50%. In addition, the B / C of wastewater was increased by about 0.2.

[0048] Table 3 uses embodiment 3 of the present invention and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com