Catalyst, preparation method and application of carbon dioxide decomposition to prepare carbon monoxide

A carbon monoxide and carbon dioxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, carbon monoxide, physical/chemical process catalyst, etc., can solve the problem of not having high temperature thermal stability, easy collapse of material structure, material sintering deactivation, etc. problems, to achieve the effect of easy industrial scale-up, lower decomposition temperature, and good performance repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

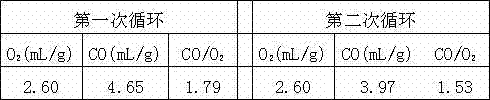

[0022] Example 1. Prepare a mixed aqueous solution according to the molar ratio of metal atoms as follows: Ce0.78Zr0.2Mg0.02 (each element is dissolved in deionized water in the form of nitrate to form a mixed aqueous solution), sodium hydroxide is made into 1 mol / L precipitant solution. At 80°C, the two solutions were co-precipitated. The precipitation process needs to be fully stirred to maintain pH = 10, aged at 80°C for 2 hours under stirring conditions, the precipitate was fully washed with deionized water, dried at 80°C and roasted at 800°C for 2 hours. , to obtain the metal oxide catalyst, the metal atom molar ratio of the catalyst is: n(Ce):n(Zr):n(Mg)=0.78:0.2:0.02, which is fully ground. The carbon dioxide decomposition cycle reaction of the catalyst of the present invention is carried out on a fixed-bed reactor. The specific reaction process is as follows: the catalyst is heated up to 1400 °C in an Ar atmosphere for thermal reduction reaction, and the reaction time...

Embodiment 2

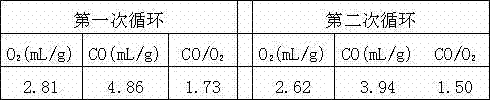

[0024]Example 2. Prepare a mixed aqueous solution according to the following molar ratio of metal atoms: Ce0.7Zr0.2Mg0.1 (each element is dissolved in deionized water in the form of nitrate to form a mixed aqueous solution), and potassium hydroxide is made into 0.5 mol / L precipitant solution. At 60°C, the two solutions were co-precipitated. The precipitation process needs to be fully stirred to maintain pH = 8, aged for 6 h under stirring at 60°C, the precipitate was fully washed with deionized water, dried at 100°C and roasted at 700°C After 4 h, the metal oxide catalyst was obtained. The metal atom molar ratio of the catalyst was: n(Ce):n(Zr):n(Mg) = 0.7:0.2:0.1, which was fully ground. The carbon dioxide decomposition cycle reaction of the catalyst of the present invention is carried out on a fixed-bed reactor. The specific reaction process is as follows: the catalyst is heated to 1400 °C in an Ar atmosphere for thermal reduction reaction, and the reaction time is 40 min; ...

Embodiment 3

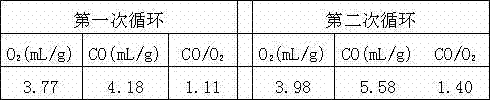

[0026] Example 3. Prepare a mixed aqueous solution according to the molar ratio of metal atoms as follows: Ce0.75Zr0.2Ca0.05 (each element is dissolved in deionized water in the form of nitrate to form a mixed aqueous solution), ammonia water is made into a 1.5 mol / L precipitant solution. At 50°C, the two solutions were co-precipitated. The precipitation process needs to be fully stirred, and the pH=12 is maintained. Aging is carried out at 50°C for 6 hours. The precipitate is fully washed with deionized water, dried at 120°C and roasted at 600°C for 4 hours. , to obtain the metal oxide catalyst, the metal atom molar ratio of the catalyst is: n(Ce):n(Zr):n(Ca)=0.75:0.2:0.05, which is fully ground. Carbon dioxide pyrolysis cycle reaction conditions are the same as example 2, and the obtained results are as follows:

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com