Metroprolol succinate sustained-release pellet and preparation method thereof

A technology of metoprolol succinate and sustained-release pellets, which is applied to a sustained-release preparation containing metoprolol succinate and its preparation, and the field of metoprolol succinate sustained-release pellets and its preparation, which can solve the problem of There are no commercialized products, difficult to obtain in large quantities, and no unified quality standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

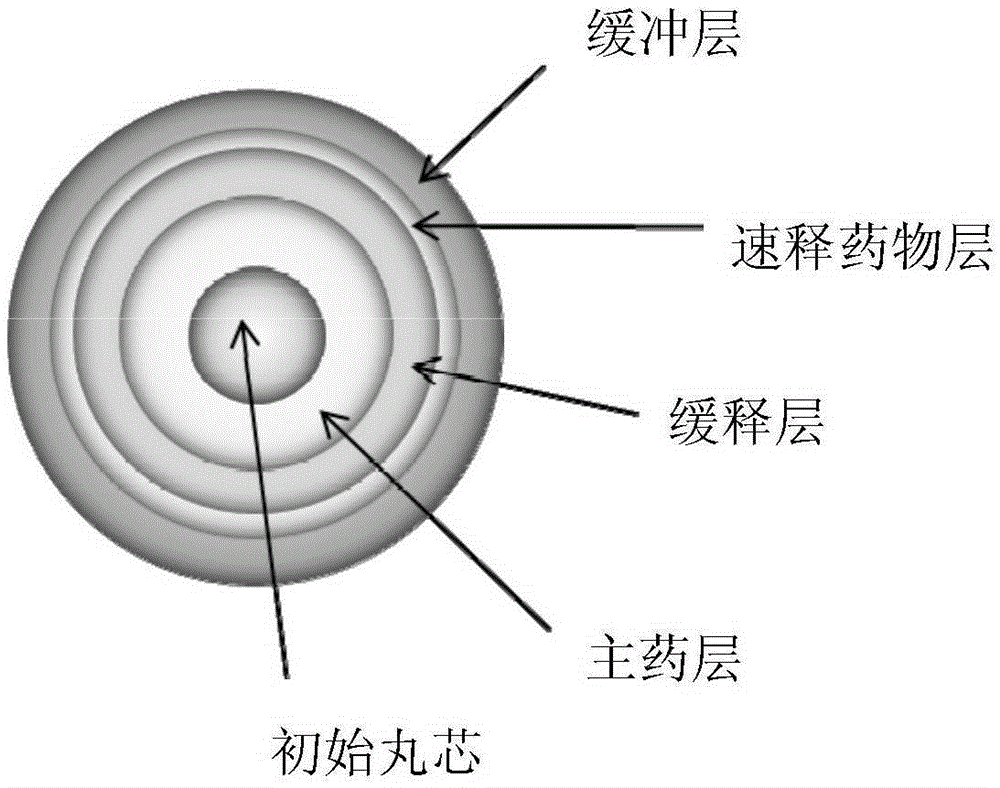

Method used

Image

Examples

Embodiment 1

[0039] Preparation of Metoprolol Succinate Sustained-Release Pellets

[0040] prescription:

[0041]

[0042]

[0043] *removed during process

[0044] Preparation Process:

[0045] 1) Dissolve metoprolol succinate and hypromellose in purified water, place the sucrose pellets in a fluidized bed, set the air inlet temperature to 50-70°C, and the air inlet volume to 70-120m 3 / h, atomization pressure 1.5~2.5bar, spray speed 6~20g / min. After the coating liquid is sprayed, keep the air inlet temperature and dry for 0.5 to 2 hours to obtain pellet A1.

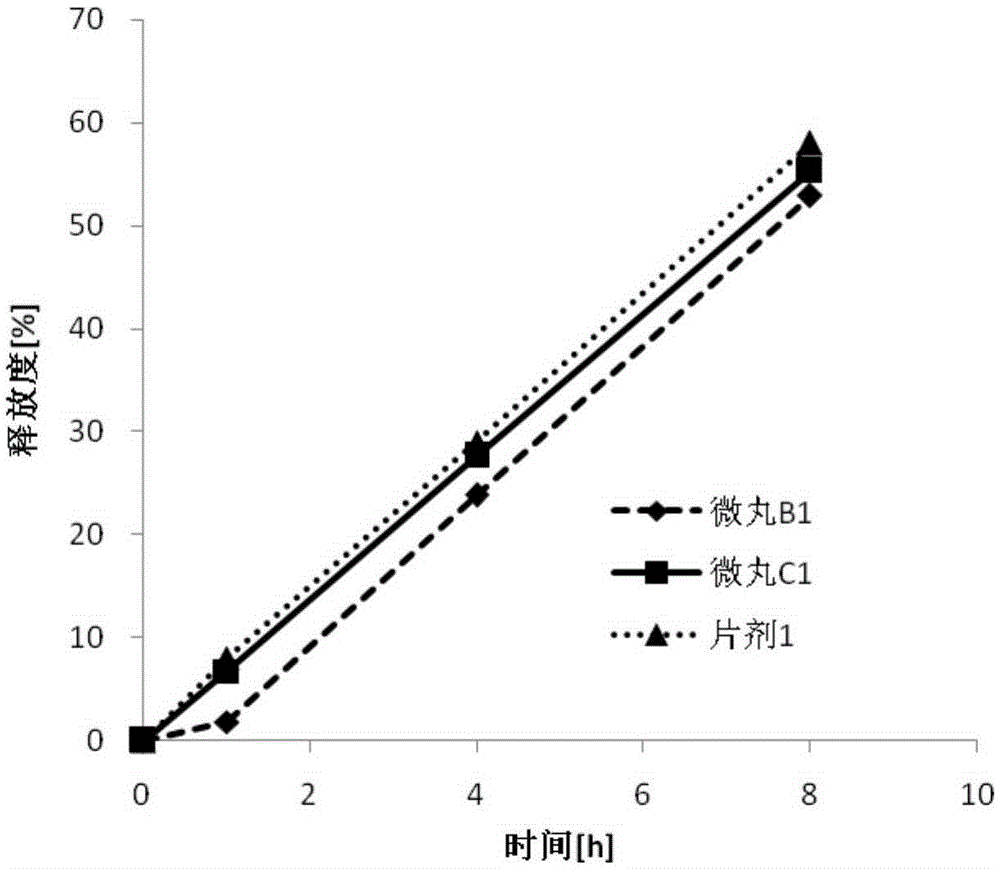

[0046] 2) Dissolve ethyl cellulose and hydroxypropyl cellulose in ethanol, place the pellets A1 prepared in the previous step in a fluidized bed, set the air inlet temperature to 40-50°C, and the air inlet volume to 70-120m 3 / h, atomization pressure 1.5~2.5bar, spray speed 3~16g / min. After the coating liquid is sprayed, keep the air inlet temperature and dry for 0.5 to 2 hours to obtain pellets B1.

[0047] 3) Put the...

Embodiment 2

[0055] Preparation of Metoprolol Succinate Sustained-Release Pellets

[0056] prescription:

[0057]

[0058]

[0059] *removed during process

[0060] Preparation Process:

[0061] 1) Dissolve metoprolol succinate and polyvinylpyrrolidone in acetone, place the sucrose pellets in a fluidized bed, set the inlet air temperature to 40-60 °C, the air inlet volume to 70 to 120 m3 / h, and the atomization pressure to 1.5 ~2.5bar, spray speed 6~20g / min. After the coating liquid is sprayed, keep the inlet air temperature and dry for 0.5-2 hours to obtain pellet A2.

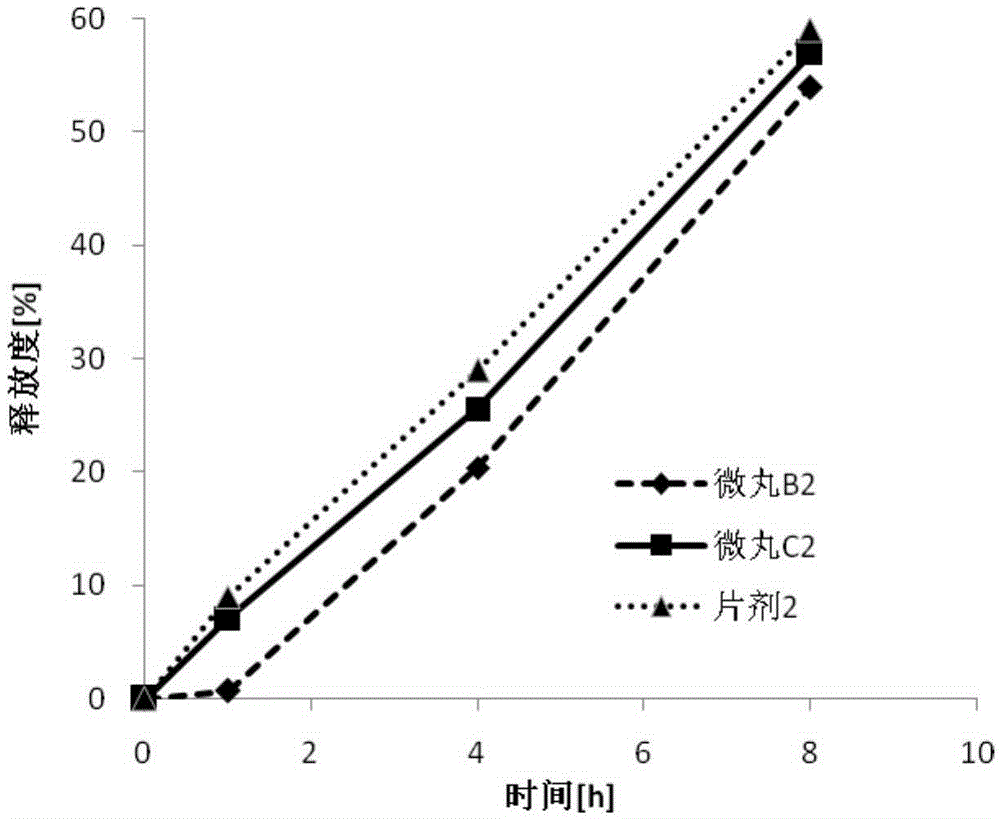

[0062] 2) Dissolve ethyl cellulose and hypromellose in methylene chloride, place the pellets A2 prepared in the previous step in a fluidized bed, set an inlet air temperature of 35 to 50 °C, and an inlet air volume of 70 to 120 m3 / h, atomization pressure 1.5~2.5bar, spray speed 3~16g / min. After the coating liquid is sprayed, keep the inlet air temperature and dry for 0.5 to 2 hours to obtain pellets B2.

[00...

Embodiment 3

[0070] Preparation of Metoprolol Succinate Sustained-Release Pellets

[0071] prescription:

[0072]

[0073] *removed during process

[0074] Preparation Process:

[0075] 1) Dissolve metoprolol succinate and hydroxypropyl cellulose in ethanol, place the sucrose pellets in a fluidized bed, set the inlet air temperature to 40-60°C, and set the inlet air volume to 70-120m 3 / h, atomization pressure 1.5~2.5bar, spray speed 6~20g / min. After the coating liquid is sprayed, keep the inlet air temperature and dry for 0.5 to 2 hours to obtain pellet A3.

[0076] 2) Dissolve ethyl cellulose and polyethylene glycol in acetone, place the pellets A3 prepared in the previous step in a fluidized bed, set an inlet air temperature of 35 to 50 °C, and an inlet air volume of 70 to 120 m3 / h, The atomization pressure is 1.5~2.5bar, and the spraying speed is 3~16g / min. After the coating liquid is sprayed, keep the air inlet temperature and dry for 0.5 to 2 hours to obtain pellets B3.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com