Micro-nano scale multiphase flow process enhanced reaction device

A micro-nano-scale, enhanced device technology, applied in chemical/physical processes, chemical/physical/physical-chemical processes, chemical instruments and methods, etc., can solve the problems of insignificant process efficiency improvement, large chemical process transformation, and technical and economical problems. Low competitiveness and other issues, to achieve the effect of small industrial amplification effect, wide range of industrial applications, and increase the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the device disclosed in the present application clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

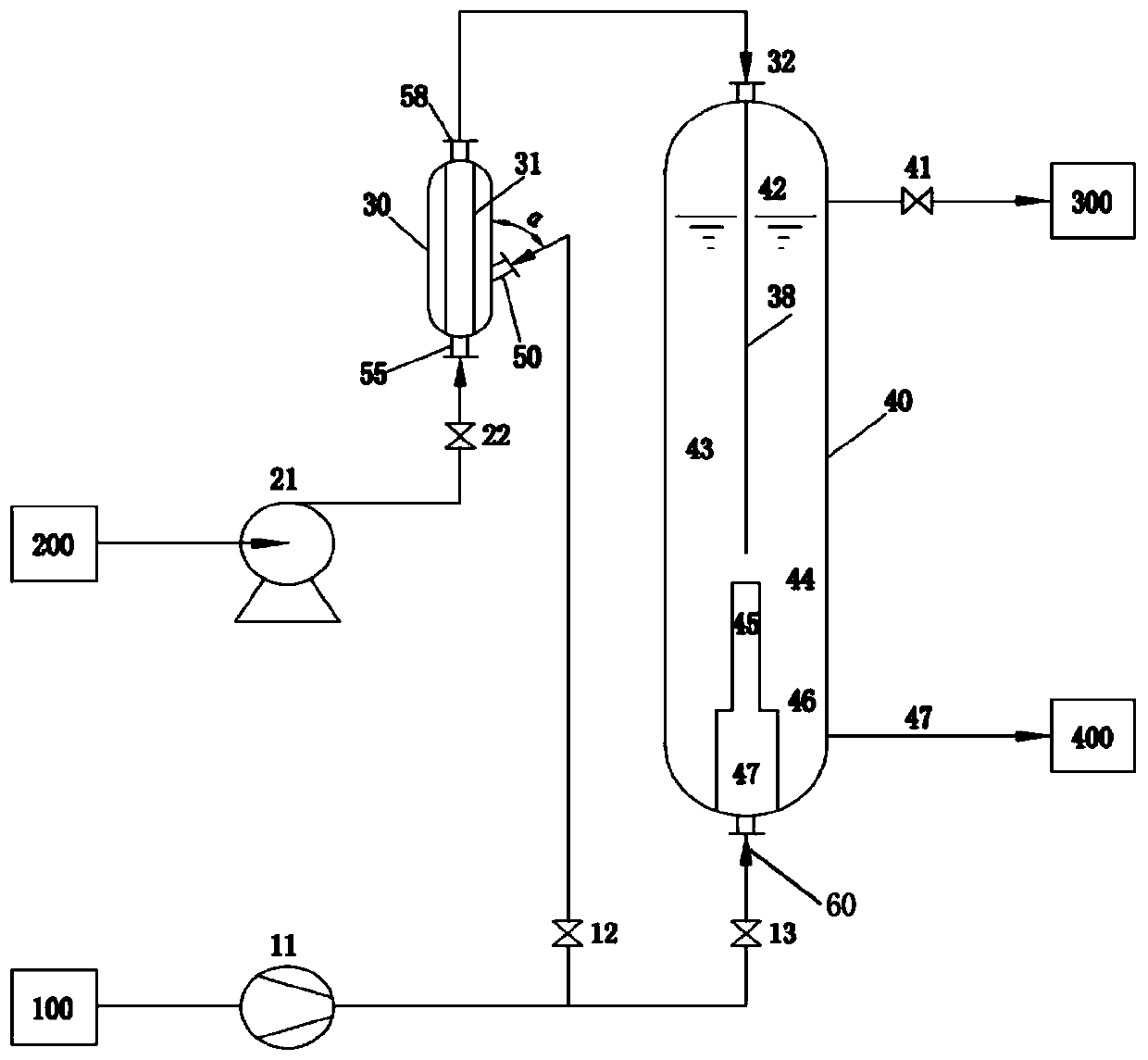

[0028] see figure 1, the present invention includes a micro-nano multiphase flow generator 30 and a multiphase flow process intensification reactor 40, the micro-nano multiphase flow generator 30 is internally provided with a micro-nano multiphase flow generator 31, and the micro-nano multiphase flow The lower end of the generator 31 is connected to the bottom liquid phase inlet 55 of the micro-nano multiphase flow generator 30, and the top is connected to the outlet 58 of the micro-nano multiphase flow generator 30. According to the fluid flow in the micro-nano multiphase flow generator 30, The amount or hydraulic load can be composed of more than two micro-nano multi-phase flow micro-element generators in parallel; the multi-phase flow process intensification reactor 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com