Preparation method of efficient sodium-based solid decarburization adsorbent

An adsorbent, sodium-based technology, which is applied in the field of preparation of high-efficiency sodium-based solid decarbonization adsorbents, can solve the problems that dopant and carrier surface are not tightly combined, sodium carbonate reaction activity is not high, reaction conversion rate is not high, and the like, Achieve high economic value and practical value, simple and easy preparation method, and easy industrial scale-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

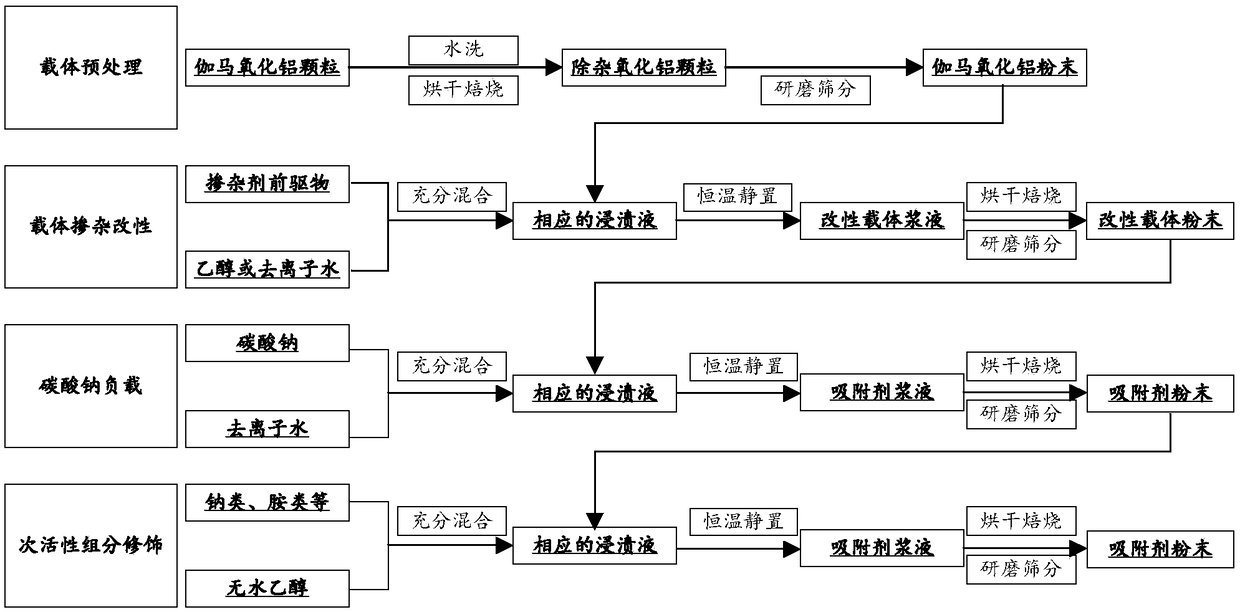

[0037] 1. Adsorbent Preparation

[0038]Weigh 50g spherical gamma alumina carrier (average diameter about 2-3mm) and 500mL glass beaker, add 400mL deionized water, let stand for 1 hour, filter dry and repeat the water washing step twice. The filter-dried carrier pellets were placed in a flat-bottomed quartz crucible and calcined in a muffle furnace at 500°C for 3 hours. After cooling to room temperature, it was taken out and ground and sieved to below 40 mesh with an agate mortar.

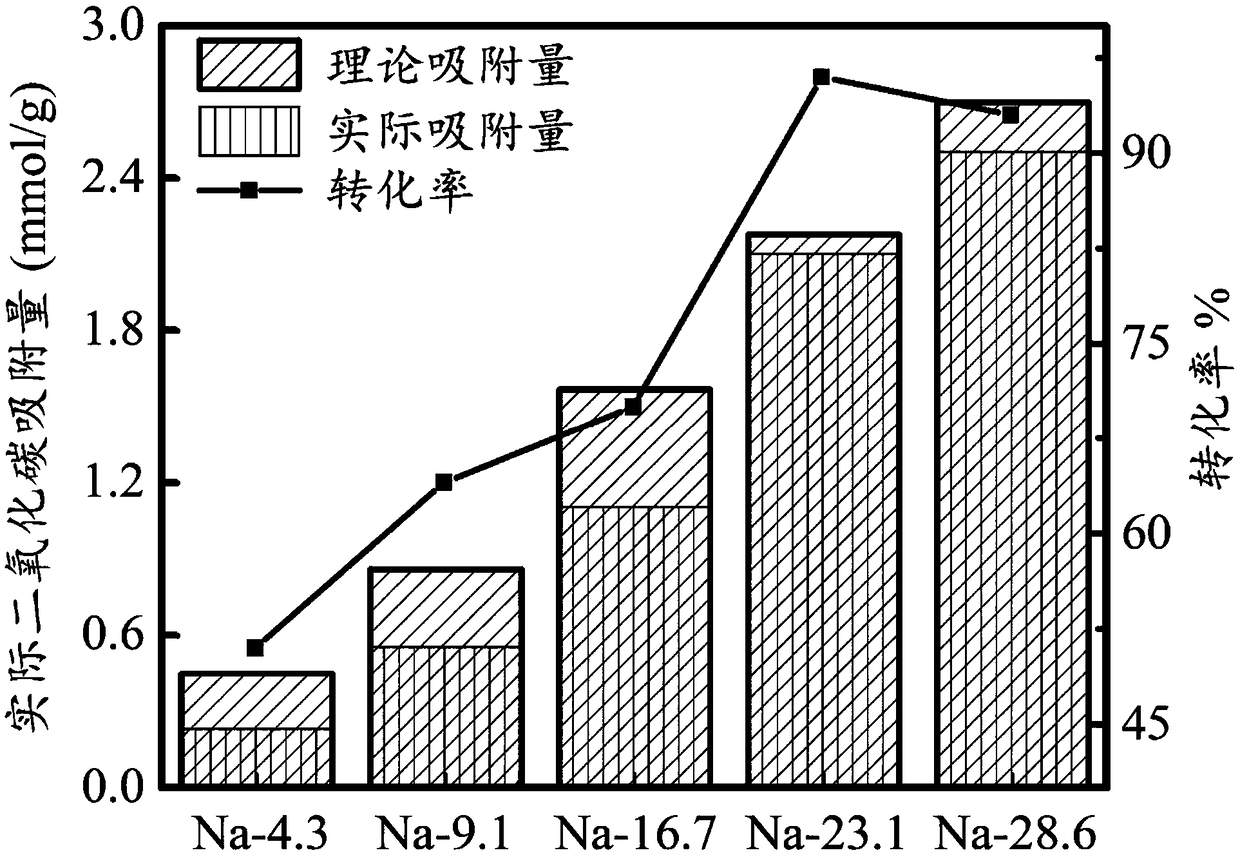

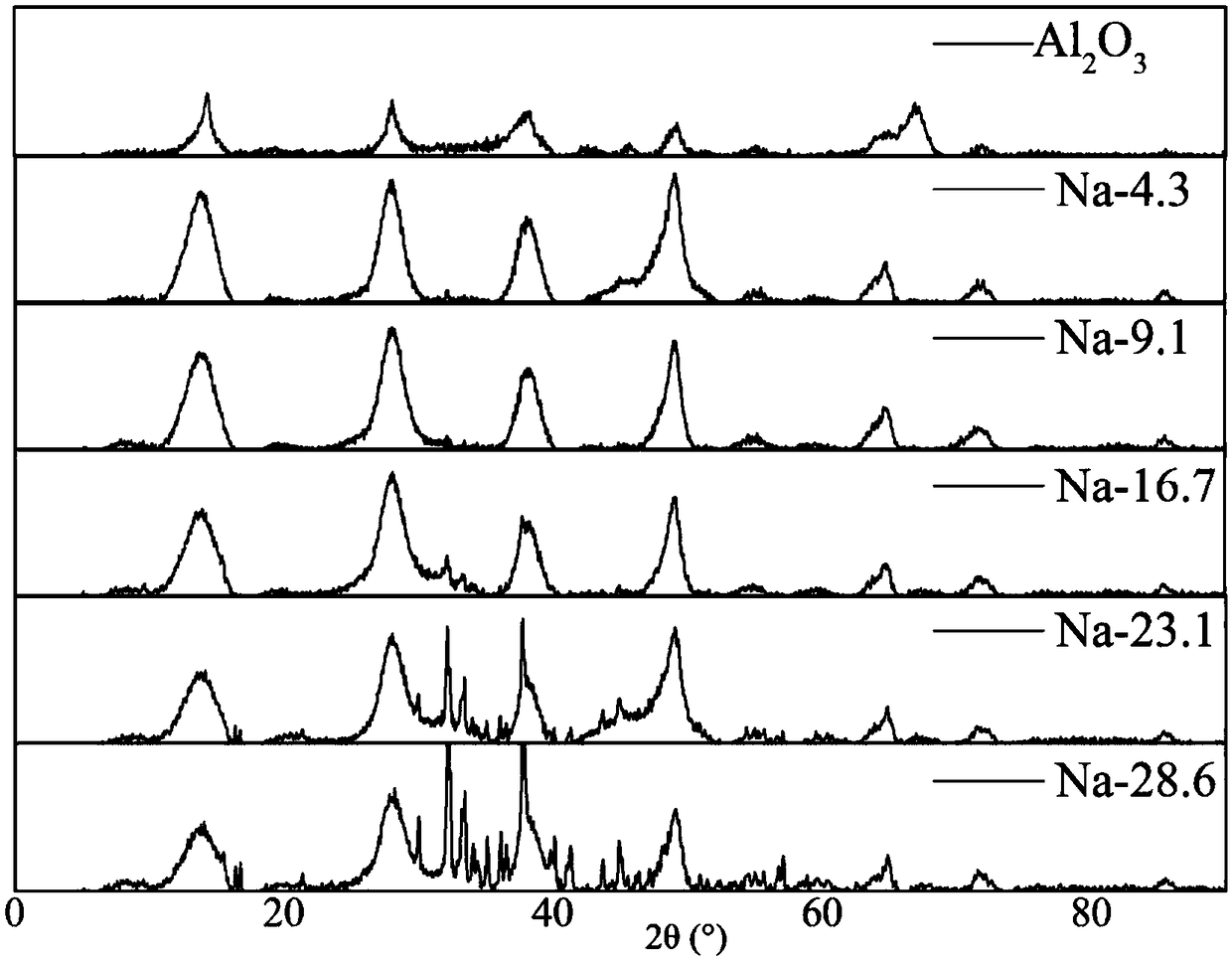

[0039] Measure 10mL of deionized water into five 25mL glass beakers, add a certain amount of sodium carbonate and fully stir until clear and transparent to ensure that the concentration of sodium carbonate solution is 0.429mol / L, 0.858mol / L, 1.715mol / L, 2.573mol / L, 3.774mol / L. Add 10 g of pretreated gamma alumina powder and stir until slurry (volume to mass ratios of sodium carbonate solution and alumina powder are 1.1:1, 1.15:1, 1.2:1, 1.25:1, 1.3:1, respectively), After standing in a constant ...

Embodiment 2

[0052] 1. Adsorbent Preparation

[0053] Weigh 10g spherical gamma alumina carrier (average diameter about 2-3mm) and 100mL glass beaker, add 80mL deionized water, let stand for 1 hour, filter dry and repeat the water washing step twice. The filter-dried carrier pellets were placed in a flat-bottomed quartz crucible and calcined in a muffle furnace at 500°C for 3 hours. After cooling to room temperature, it was taken out and ground and sieved to below 40 mesh with an agate mortar.

[0054] Measure 10 mL of absolute ethanol into a 25 mL glass beaker, add a certain amount of butyl titanate and stir thoroughly to ensure that the concentration of titanium ions is 0.15 mol / L. Add 10 g of pretreated gamma alumina powder and stir until slurry (volume mass ratio of impregnating liquid to carrier powder is 1.1:1), put it in a constant temperature water bath at 40°C for 8 hours, then bake it in a muffle furnace at 500°C 3 hours. After cooling to room temperature, it was taken out and...

Embodiment 3

[0061] 1. Adsorbent Preparation

[0062] Weigh 10g spherical gamma alumina carrier (average diameter about 2-3mm) and 100mL glass beaker, add 80mL deionized water, let stand for 1 hour, filter dry and repeat the water washing step twice. The filter-dried carrier pellets were placed in a flat-bottomed quartz crucible and calcined in a muffle furnace at 500°C for 3 hours. After cooling to room temperature, it was taken out and ground and sieved to below 40 mesh with an agate mortar.

[0063] Measure 10 mL of deionized water into a 25 mL glass beaker, add a certain amount of ferric nitrate and stir thoroughly to ensure that the concentration of ferric ions is 0.15 mol / L (the volume-to-mass ratio of impregnation solution to carrier powder is 1.3:1). Add 10 g of pretreated gamma alumina powder and stir until it becomes a slurry, let it stand in a constant temperature water bath at 40°C for 8 hours, then bake it in a muffle furnace at 500°C for 3 hours. After cooling to room tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| carbon dioxide adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com